Gypsum lath offers a smooth, moisture-resistant surface ideal for interior walls and ceilings, providing excellent fire resistance and ease of installation compared to metal lath. Metal lath, typically made of galvanized steel, is preferred for exterior applications and plaster reinforcement due to its superior strength and durability in harsh environments. Choosing between gypsum lath and metal lath depends on the specific project requirements, including exposure to moisture, structural support, and finishing preferences.

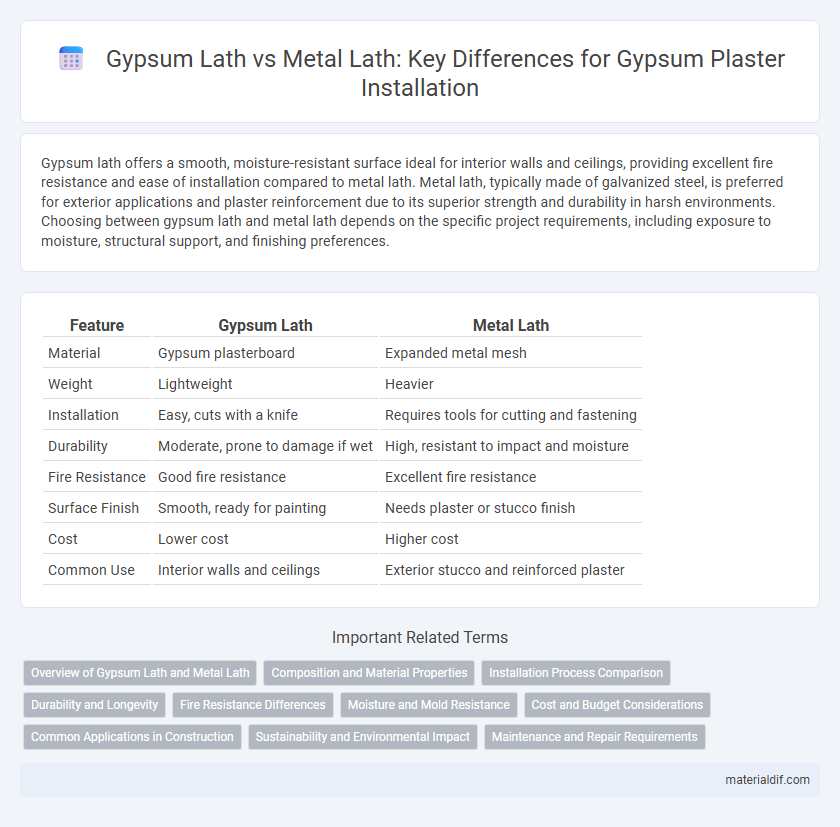

Table of Comparison

| Feature | Gypsum Lath | Metal Lath |

|---|---|---|

| Material | Gypsum plasterboard | Expanded metal mesh |

| Weight | Lightweight | Heavier |

| Installation | Easy, cuts with a knife | Requires tools for cutting and fastening |

| Durability | Moderate, prone to damage if wet | High, resistant to impact and moisture |

| Fire Resistance | Good fire resistance | Excellent fire resistance |

| Surface Finish | Smooth, ready for painting | Needs plaster or stucco finish |

| Cost | Lower cost | Higher cost |

| Common Use | Interior walls and ceilings | Exterior stucco and reinforced plaster |

Overview of Gypsum Lath and Metal Lath

Gypsum lath is a lightweight backing material made from plasterboard or gypsum panels, commonly used in interior walls and ceilings to provide a smooth surface for finishing. Metal lath consists of expanded or woven metal mesh, offering superior strength, durability, and excellent adhesion for plaster or stucco, making it ideal for both interior and exterior applications. While gypsum lath is easier to install and fire-resistant, metal lath excels in structural reinforcement and moisture resistance.

Composition and Material Properties

Gypsum lath is composed primarily of a gypsum core encased in paper facings, offering excellent fire resistance and ease of cutting, while metal lath is made from galvanized steel or expanded metal mesh, providing superior strength and durability. The paper facing on gypsum lath enhances sound insulation and moisture resistance, whereas metal lath serves as a robust base for plaster application, especially in exterior or high-impact environments. Metal lath's corrosion resistance and rigidity make it ideal for structural support, contrasting with gypsum lath's lightweight, smooth surface optimized for interior finishing.

Installation Process Comparison

Gypsum lath installation involves fastening lightweight gypsum panels directly to framing, offering faster setup with minimal cutting or shaping required compared to metal lath. Metal lath installation requires securing expanded metal mesh to studs, followed by applying multiple coats of plaster for a durable finish, resulting in a more labor-intensive and time-consuming process. The simpler handling and reduced material preparation make gypsum lath preferred for expedited drywall applications, while metal lath suits projects demanding higher strength and impact resistance.

Durability and Longevity

Gypsum lath offers moderate durability but is more prone to damage from moisture and impact compared to metal lath, which provides superior strength and resistance to corrosion and cracking. Metal lath's galvanized steel composition enhances its longevity, making it ideal for exterior applications or areas with high humidity. The choice between gypsum and metal lath significantly affects the lifespan and maintenance requirements of plaster or stucco finishes.

Fire Resistance Differences

Gypsum lath offers superior fire resistance due to its non-combustible, moisture-resistant core that slows heat transfer and provides a durable barrier against flames. Metal lath, while structurally strong and often used as a base for plaster, lacks inherent fire-resistant properties and may conduct heat, potentially compromising fire containment. Fire-rated gypsum lath systems meet strict building codes for fire safety, making them a preferred choice in fire-sensitive applications over metal lath.

Moisture and Mold Resistance

Gypsum lath offers superior moisture resistance compared to metal lath, making it ideal for environments prone to humidity and damp conditions. Its sulfur component inherently inhibits mold growth, enhancing indoor air quality and structural longevity. Metal lath, while durable, is more susceptible to rust and mold buildup when exposed to prolonged moisture.

Cost and Budget Considerations

Gypsum lath offers a lower upfront cost compared to metal lath, making it more budget-friendly for residential projects. Metal lath, while more expensive initially, provides enhanced durability and long-term value in commercial or high-moisture environments. Evaluating project requirements and lifecycle expenses is essential to determine the most cost-effective lath option.

Common Applications in Construction

Gypsum lath is commonly used in residential interior wall and ceiling applications, providing a smooth base for plaster finishes and enhancing fire resistance. Metal lath is preferred in commercial and exterior construction, offering superior durability and support for heavy stucco or cement plaster. Both materials improve plaster adherence but are selected based on structural requirements and environmental exposure.

Sustainability and Environmental Impact

Gypsum lath offers greater sustainability compared to metal lath due to its lower embodied energy and recyclability, contributing to reduced carbon emissions during production and disposal. Unlike metal lath, gypsum lath is biodegradable and often made from abundant natural materials like calcium sulfate dihydrate, minimizing environmental impact. Choosing gypsum lath supports eco-friendly construction by enhancing indoor air quality and reducing resource depletion in building projects.

Maintenance and Repair Requirements

Gypsum lath requires less frequent maintenance due to its resistance to rust and corrosion, making it ideal for interior applications where moisture exposure is low. Metal lath, while stronger and more durable in high-impact areas, is prone to rust and requires regular inspection and possible replacement in humid or wet conditions. Repairing gypsum lath is generally simpler and involves patching with joint compound, whereas metal lath repair often demands welding or replacement of damaged sections.

Gypsum lath vs Metal lath Infographic

materialdif.com

materialdif.com