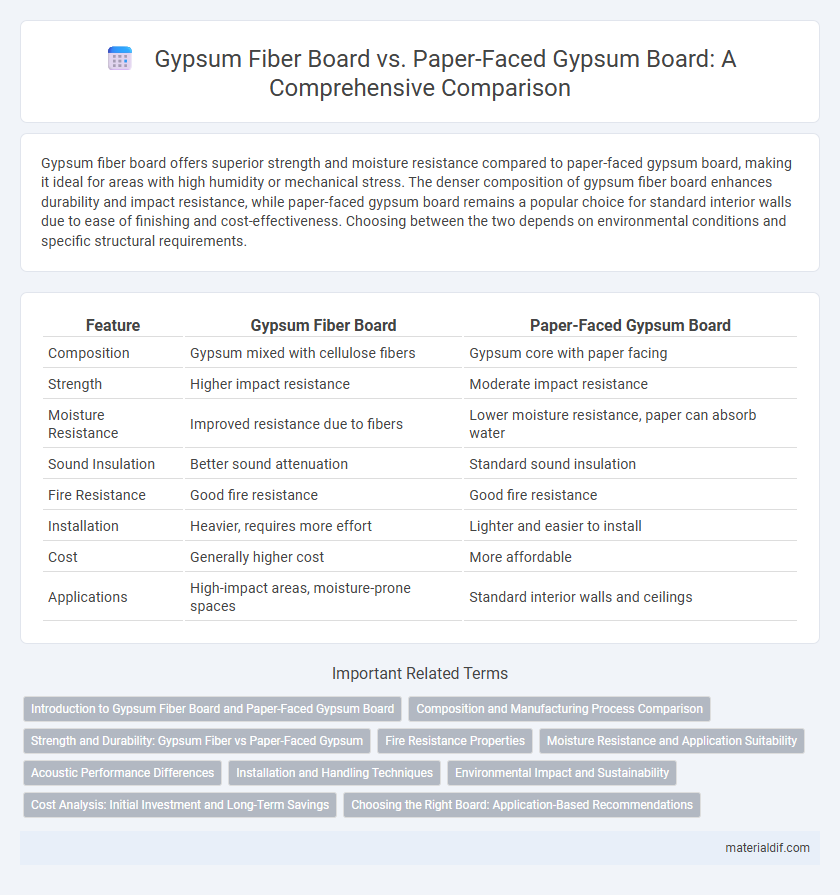

Gypsum fiber board offers superior strength and moisture resistance compared to paper-faced gypsum board, making it ideal for areas with high humidity or mechanical stress. The denser composition of gypsum fiber board enhances durability and impact resistance, while paper-faced gypsum board remains a popular choice for standard interior walls due to ease of finishing and cost-effectiveness. Choosing between the two depends on environmental conditions and specific structural requirements.

Table of Comparison

| Feature | Gypsum Fiber Board | Paper-Faced Gypsum Board |

|---|---|---|

| Composition | Gypsum mixed with cellulose fibers | Gypsum core with paper facing |

| Strength | Higher impact resistance | Moderate impact resistance |

| Moisture Resistance | Improved resistance due to fibers | Lower moisture resistance, paper can absorb water |

| Sound Insulation | Better sound attenuation | Standard sound insulation |

| Fire Resistance | Good fire resistance | Good fire resistance |

| Installation | Heavier, requires more effort | Lighter and easier to install |

| Cost | Generally higher cost | More affordable |

| Applications | High-impact areas, moisture-prone spaces | Standard interior walls and ceilings |

Introduction to Gypsum Fiber Board and Paper-Faced Gypsum Board

Gypsum fiber board is a composite panel made from gypsum core reinforced with cellulose fibers, offering enhanced strength, impact resistance, and moisture durability compared to traditional paper-faced gypsum board, which consists of a calcined gypsum core sandwiched between two layers of paper. The incorporation of cellulose fibers in gypsum fiber board improves structural integrity and fire resistance, making it suitable for demanding environments. In contrast, paper-faced gypsum board remains the most common interior wall and ceiling material due to its cost-effectiveness and ease of installation but has lower resistance to impact and moisture.

Composition and Manufacturing Process Comparison

Gypsum fiber board consists of gypsum combined with cellulose fibers, creating a dense, uniform panel formed under high pressure and heat, which enhances strength and moisture resistance. Paper-faced gypsum board is composed of a gypsum core encased in paper liners on both sides, produced by continuously shaping and setting the slurry between paper sheets in a conveyor process. The inclusion of cellulose fibers in gypsum fiber board differentiates its composition and manufacturing, resulting in improved durability compared to the traditional paper-faced variant.

Strength and Durability: Gypsum Fiber vs Paper-Faced Gypsum

Gypsum fiber board offers superior strength and durability due to its composite structure reinforced with cellulose fibers, making it more resistant to impacts and sagging compared to traditional paper-faced gypsum board. The fiber reinforcement enhances flexibility and reduces susceptibility to cracking and water damage, extending the board's lifespan in high-traffic or moisture-prone environments. Paper-faced gypsum board, while economical and easy to handle, lacks the robust tensile strength and impact resistance characteristic of gypsum fiber boards, leading to more frequent repairs and replacements.

Fire Resistance Properties

Gypsum fiber board demonstrates enhanced fire resistance compared to paper-faced gypsum board due to its dense composition and the absence of combustible paper facing. The fiber-reinforced structure improves thermal insulation and slows heat transfer, providing better performance in fire scenarios. In contrast, paper-faced gypsum board's organic paper layer can ignite or contribute to smoke generation, reducing its overall fire resistance.

Moisture Resistance and Application Suitability

Gypsum fiber board exhibits superior moisture resistance compared to paper-faced gypsum board, making it ideal for high-humidity environments such as bathrooms and kitchens. The dense fiber matrix in gypsum fiber boards reduces water absorption, enhancing durability and mold resistance. Paper-faced gypsum boards, while easier to install and finish, are better suited for interior applications with low moisture exposure.

Acoustic Performance Differences

Gypsum fiber board offers superior acoustic performance compared to paper-faced gypsum board due to its dense fiber composition that enhances sound insulation and reduces noise transmission. The composite structure of gypsum fiber boards increases sound absorption coefficients, making them ideal for spaces requiring high acoustic control such as recording studios or office partitions. Paper-faced gypsum boards typically provide lower soundproofing capabilities because the paper layer is less effective at dampening sound vibrations.

Installation and Handling Techniques

Gypsum fiber board offers enhanced durability and moisture resistance, making installation less prone to damage during handling compared to paper-faced gypsum board. Its denser composition requires specific cutting tools and slower fastening speeds to prevent material cracking. Paper-faced gypsum board is lighter and easier to cut but demands careful handling to avoid tearing the paper surface, especially during transportation and mounting.

Environmental Impact and Sustainability

Gypsum fiber boards are made from recycled cellulose fibers combined with gypsum, offering enhanced sustainability through reduced waste and lower embodied energy compared to paper-faced gypsum boards, which primarily use virgin paper products that contribute to deforestation and higher carbon footprints. The manufacturing process of gypsum fiber boards typically involves fewer chemical additives, resulting in lower emissions and improved recyclability at end-of-life. Consequently, gypsum fiber boards provide a more environmentally responsible building material choice with reduced ecological impact and better alignment with green building certifications such as LEED.

Cost Analysis: Initial Investment and Long-Term Savings

Gypsum fiber board typically demands a higher initial investment than paper-faced gypsum board due to its enhanced durability and moisture resistance. However, the long-term savings arise from reduced maintenance, lower replacement frequency, and improved fire resistance, making it cost-effective over time. Paper-faced gypsum board offers lower upfront costs but may incur higher expenses related to repairs and replacements in high-moisture or high-impact environments.

Choosing the Right Board: Application-Based Recommendations

Gypsum fiber board offers superior moisture resistance and impact durability, making it ideal for high-humidity areas and commercial spaces requiring enhanced strength. Paper-faced gypsum board remains a cost-effective solution best suited for interior walls and ceilings in dry, low-traffic environments. Selecting the right board depends on specific application needs such as moisture exposure, load-bearing requirements, and budget constraints.

Gypsum fiber board vs Paper-faced gypsum board Infographic

materialdif.com

materialdif.com