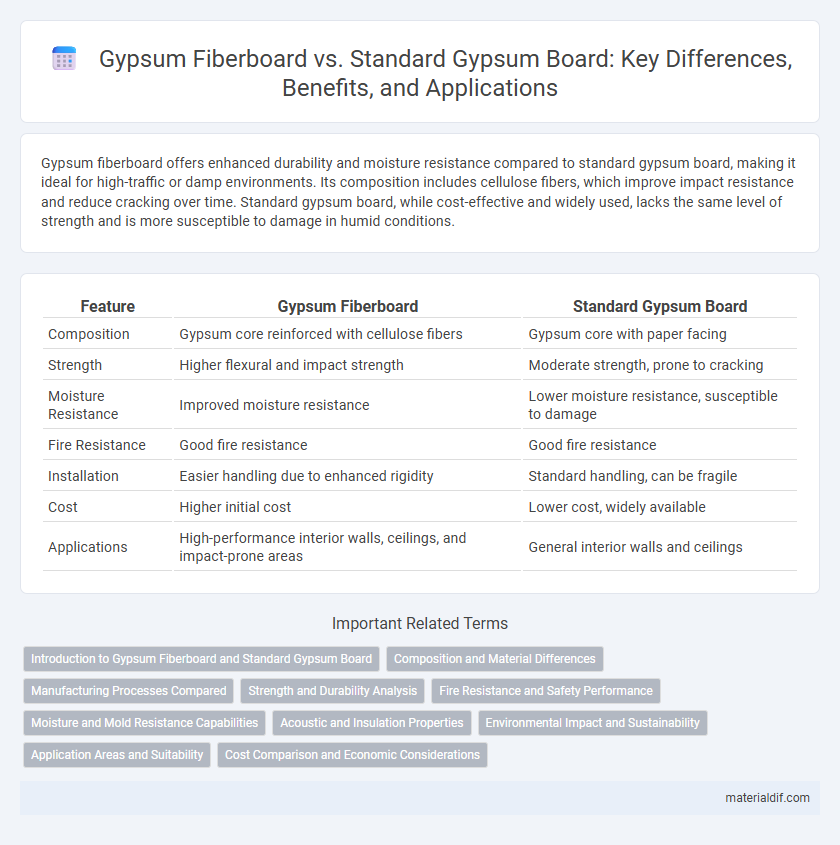

Gypsum fiberboard offers enhanced durability and moisture resistance compared to standard gypsum board, making it ideal for high-traffic or damp environments. Its composition includes cellulose fibers, which improve impact resistance and reduce cracking over time. Standard gypsum board, while cost-effective and widely used, lacks the same level of strength and is more susceptible to damage in humid conditions.

Table of Comparison

| Feature | Gypsum Fiberboard | Standard Gypsum Board |

|---|---|---|

| Composition | Gypsum core reinforced with cellulose fibers | Gypsum core with paper facing |

| Strength | Higher flexural and impact strength | Moderate strength, prone to cracking |

| Moisture Resistance | Improved moisture resistance | Lower moisture resistance, susceptible to damage |

| Fire Resistance | Good fire resistance | Good fire resistance |

| Installation | Easier handling due to enhanced rigidity | Standard handling, can be fragile |

| Cost | Higher initial cost | Lower cost, widely available |

| Applications | High-performance interior walls, ceilings, and impact-prone areas | General interior walls and ceilings |

Introduction to Gypsum Fiberboard and Standard Gypsum Board

Gypsum fiberboard combines gypsum with cellulose fibers to enhance strength, moisture resistance, and durability compared to standard gypsum board, which primarily consists of a gypsum core sandwiched between paper facings. Standard gypsum board, commonly used in interior walls and ceilings, offers ease of installation and cost-efficiency but lacks the reinforced structural properties of gypsum fiberboard. The integration of fibers in gypsum fiberboard improves impact resistance and reduces susceptibility to sagging and warping in humid environments.

Composition and Material Differences

Gypsum fiberboard incorporates cellulose fibers and synthetic additives mixed with gypsum, enhancing strength, flexibility, and moisture resistance compared to standard gypsum board. Standard gypsum board primarily consists of a gypsum core sandwiched between paper facings, which provides basic fire resistance and soundproofing but lacks the increased durability of fiber-reinforced panels. The addition of natural fibers in gypsum fiberboard improves insulation properties and reduces the risk of cracking and sagging under load.

Manufacturing Processes Compared

Gypsum fiberboard is manufactured by incorporating cellulose fibers into the gypsum slurry, enhancing strength and moisture resistance, whereas standard gypsum board consists primarily of calcium sulfate dihydrate layered between paper facings. The addition of fibers in gypsum fiberboard improves dimensional stability and impact resistance during production, involving a more complex curing and drying process compared to the conventional process of forming and setting gypsum slurry in standard boards. Manufacturing gypsum fiberboard demands precise control over fiber distribution and slurry consistency, resulting in a denser, more durable product suited for specialized construction applications.

Strength and Durability Analysis

Gypsum fiberboard exhibits superior strength and durability compared to standard gypsum board due to its dense composition reinforced with cellulose fibers, enhancing resistance to impact and flexural stress. This fiber reinforcement reduces cracking and improves load-bearing capacity, making gypsum fiberboard ideal for high-traffic or moisture-prone environments. Standard gypsum board, while cost-effective and easy to install, lacks the enhanced toughness and long-term durability offered by fiberboard variants.

Fire Resistance and Safety Performance

Gypsum fiberboard offers enhanced fire resistance compared to standard gypsum board due to its composition, which includes cellulose fibers that improve structural integrity during high heat exposure. This increased fire resistance results in higher safety performance, making gypsum fiberboard suitable for applications requiring stringent fire ratings and improved durability under fire conditions. Standard gypsum board, while fire-resistant, typically provides lower thermal insulation and less structural stability in prolonged fire scenarios.

Moisture and Mold Resistance Capabilities

Gypsum fiberboard offers superior moisture resistance compared to standard gypsum board due to its denser composition and enhanced water-repellent properties, making it ideal for high-humidity environments. The fiber-reinforced matrix inhibits mold growth more effectively by reducing water absorption and maintaining structural integrity under damp conditions. Standard gypsum board, while cost-effective, is more susceptible to moisture damage and mold proliferation, limiting its use in moisture-prone areas.

Acoustic and Insulation Properties

Gypsum fiberboard offers enhanced acoustic performance due to its denser composition, which effectively reduces sound transmission compared to standard gypsum board. The fiber reinforcement improves thermal insulation by minimizing heat transfer, making gypsum fiberboard a superior choice for energy-efficient building applications. Standard gypsum board provides basic insulation but lacks the sound dampening and thermal resistance capabilities inherent in gypsum fiberboard products.

Environmental Impact and Sustainability

Gypsum fiberboard offers improved environmental benefits compared to standard gypsum board due to its use of recycled cellulose fibers, which reduce reliance on virgin materials and decrease landfill waste. The production process of gypsum fiberboard typically consumes less energy and generates fewer emissions, enhancing its sustainability profile. Unlike traditional gypsum board, fiberboard also demonstrates better biodegradability, supporting circular economy practices in building materials.

Application Areas and Suitability

Gypsum fiberboard offers enhanced durability and moisture resistance, making it ideal for high-humidity environments like bathrooms and kitchens, whereas standard gypsum board is predominantly used for interior walls and ceilings in dry areas. The fiberboard's dense composition supports heavy-duty applications, including exterior sheathing and fire-rated assemblies, while standard gypsum board suits basic partitioning and acoustic control. Selecting between the two depends on factors such as moisture exposure, impact resistance, and fire safety requirements.

Cost Comparison and Economic Considerations

Gypsum fiberboard typically incurs higher upfront costs compared to standard gypsum board due to its composite materials and manufacturing process. However, its enhanced durability and moisture resistance can reduce long-term maintenance and replacement expenses, offering better economic value in humid or high-traffic environments. Standard gypsum board remains more cost-effective for budget-conscious projects with low exposure to environmental stressors, making material selection dependent on specific application requirements and lifecycle cost analysis.

Gypsum fiberboard vs Standard gypsum board Infographic

materialdif.com

materialdif.com