Paper-faced gypsum boards offer superior ease of finishing and paint adhesion due to their absorbent paper surface, making them a preferred choice for interior walls and ceilings. Glass-mat gypsum boards feature a moisture-resistant fiberglass mat surface, enhancing durability and mold resistance, ideal for high-humidity environments such as bathrooms and basements. Both types provide fire resistance and structural support, but selecting between them depends on the specific requirements of moisture control and finishing quality.

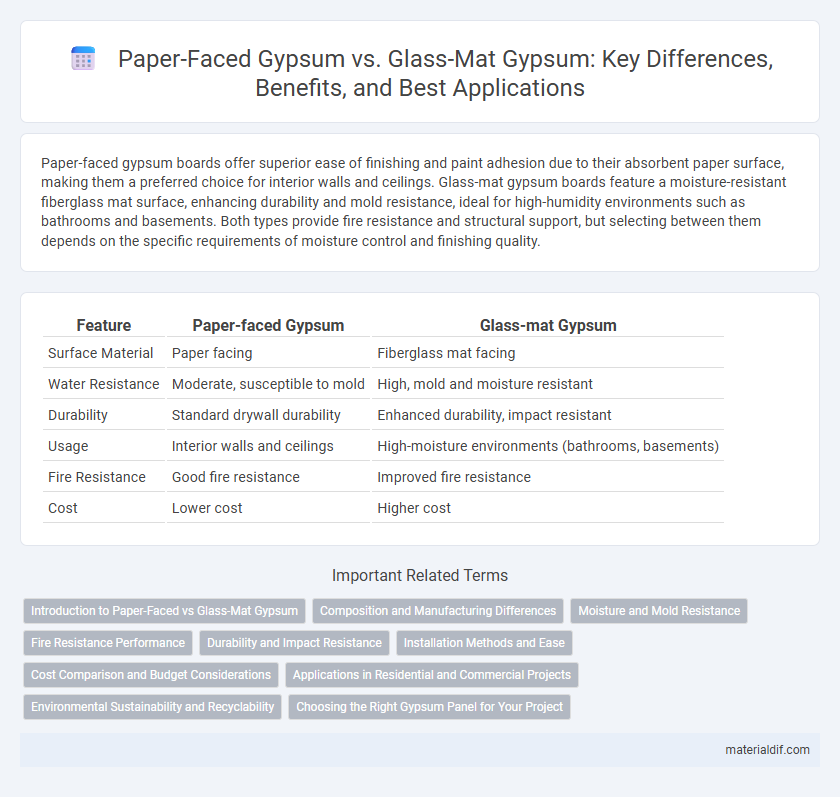

Table of Comparison

| Feature | Paper-faced Gypsum | Glass-mat Gypsum |

|---|---|---|

| Surface Material | Paper facing | Fiberglass mat facing |

| Water Resistance | Moderate, susceptible to mold | High, mold and moisture resistant |

| Durability | Standard drywall durability | Enhanced durability, impact resistant |

| Usage | Interior walls and ceilings | High-moisture environments (bathrooms, basements) |

| Fire Resistance | Good fire resistance | Improved fire resistance |

| Cost | Lower cost | Higher cost |

Introduction to Paper-Faced vs Glass-Mat Gypsum

Paper-faced gypsum boards feature a cellulose paper facing that provides a smooth surface ideal for painting and finishing, commonly used in interior wall and ceiling applications. Glass-mat gypsum boards utilize fiberglass mats instead of paper, offering superior moisture resistance, mold resistance, and durability in high-humidity environments such as bathrooms and commercial kitchens. Selection between paper-faced and glass-mat gypsum depends on project requirements, with glass-mat favored for moisture-prone areas and paper-faced preferred for standard interior drywall installations.

Composition and Manufacturing Differences

Paper-faced gypsum consists of a core made from natural gypsum plaster applied between layers of heavy paper, providing a smooth surface ideal for painting and finishing. Glass-mat gypsum replaces the paper facing with fiberglass mats bonded to the gypsum core, enhancing moisture resistance and durability. Manufacturing paper-faced gypsum involves pressing the gypsum slurry between paper sheets, while glass-mat gypsum production requires embedding fiberglass mats into the gypsum slurry before curing.

Moisture and Mold Resistance

Paper-faced gypsum typically offers less moisture and mold resistance due to its organic paper facing, which can absorb water and foster mold growth over time. Glass-mat gypsum features a fiberglass mat facing that provides superior resistance to moisture and inhibits mold development, making it ideal for high-humidity environments. These moisture-resistant properties make glass-mat gypsum preferred in bathrooms, basements, and other areas prone to damp conditions.

Fire Resistance Performance

Paper-faced gypsum boards typically offer moderate fire resistance due to their organic paper facings, which can char and burn under high temperatures. Glass-mat gypsum boards contain non-combustible fiberglass mats that enhance fire resistance by maintaining structural integrity and limiting flame spread during exposure to fire. Fire resistance ratings for glass-mat gypsum often exceed those of paper-faced products, making them suitable for applications requiring stringent fire safety standards.

Durability and Impact Resistance

Paper-faced gypsum offers moderate durability and impact resistance, suitable for standard interior wall applications where moisture exposure is minimal. Glass-mat gypsum, reinforced with fiberglass matting, provides superior durability and high impact resistance, making it ideal for high-traffic areas and environments prone to moisture or humidity. The fiberglass content in glass-mat gypsum enhances structural integrity and prevents mold growth, outperforming traditional paper-faced gypsum in longevity and resilience.

Installation Methods and Ease

Paper-faced gypsum boards are installed using standard drywall techniques such as taping, mudding, and sanding, making them widely familiar to contractors and relatively easy to work with. Glass-mat gypsum boards often require specific adhesives or mechanical fasteners and may need specialized cutting tools due to their moisture-resistant glass-mat surface. The ease of installation for paper-faced gypsum is generally higher for typical interior applications, while glass-mat gypsum provides better performance in wet areas at the cost of more careful handling and installation.

Cost Comparison and Budget Considerations

Paper-faced gypsum boards generally cost less than glass-mat gypsum boards, making them a more budget-friendly option for standard interior wall applications. Glass-mat gypsum, while pricier, offers enhanced moisture resistance and durability, which can reduce long-term maintenance and replacement expenses in high-humidity or corrosive environments. Project budgets should consider initial material costs alongside performance benefits to determine the most cost-effective solution.

Applications in Residential and Commercial Projects

Paper-faced gypsum boards are widely used in residential and commercial projects for interior walls and ceilings due to their smooth surface, ease of finishing, and cost-effectiveness. Glass-mat gypsum boards offer superior moisture resistance and durability, making them ideal for areas prone to humidity such as bathrooms, kitchens, and commercial spaces requiring enhanced mold and fire resistance. Both materials support efficient installation and finishing, but selection depends on specific environmental conditions and project performance requirements.

Environmental Sustainability and Recyclability

Paper-faced gypsum boards are traditionally made with cellulose fibers, which are biodegradable and promote easier recycling, enhancing environmental sustainability by reducing landfill waste. Glass-mat gypsum boards employ fiberglass mats that, while offering superior moisture resistance and durability, present more complex recycling challenges due to the combination of inorganic and synthetic materials. Sustainable construction favors paper-faced gypsum when prioritizing recyclability and lower environmental impact, although advancements in glass-mat recycling technologies are improving their eco-friendly profile.

Choosing the Right Gypsum Panel for Your Project

Paper-faced gypsum panels offer excellent compatibility with paint and easy finishing, making them ideal for interior walls and ceilings in dry environments. Glass-mat gypsum panels provide superior moisture resistance and mold inhibition, suited for high-humidity areas such as bathrooms and basements. Selecting the right gypsum panel depends on specific project needs, including moisture exposure and desired durability.

Paper-faced gypsum vs Glass-mat gypsum Infographic

materialdif.com

materialdif.com