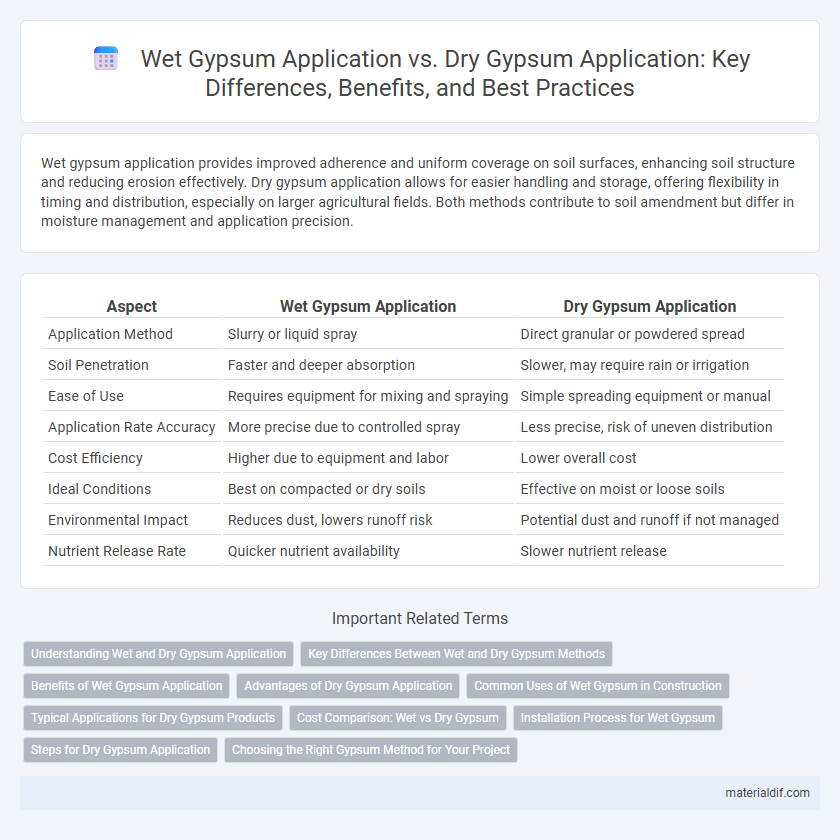

Wet gypsum application provides improved adherence and uniform coverage on soil surfaces, enhancing soil structure and reducing erosion effectively. Dry gypsum application allows for easier handling and storage, offering flexibility in timing and distribution, especially on larger agricultural fields. Both methods contribute to soil amendment but differ in moisture management and application precision.

Table of Comparison

| Aspect | Wet Gypsum Application | Dry Gypsum Application |

|---|---|---|

| Application Method | Slurry or liquid spray | Direct granular or powdered spread |

| Soil Penetration | Faster and deeper absorption | Slower, may require rain or irrigation |

| Ease of Use | Requires equipment for mixing and spraying | Simple spreading equipment or manual |

| Application Rate Accuracy | More precise due to controlled spray | Less precise, risk of uneven distribution |

| Cost Efficiency | Higher due to equipment and labor | Lower overall cost |

| Ideal Conditions | Best on compacted or dry soils | Effective on moist or loose soils |

| Environmental Impact | Reduces dust, lowers runoff risk | Potential dust and runoff if not managed |

| Nutrient Release Rate | Quicker nutrient availability | Slower nutrient release |

Understanding Wet and Dry Gypsum Application

Wet gypsum application involves mixing gypsum with water to create a slurry, ensuring even coverage and better adhesion on surfaces such as walls and ceilings. Dry gypsum application uses powdered gypsum directly in processes like drywall installation or patching, offering faster setup times without the need for mixing. Understanding the differences helps optimize usage based on project requirements, moisture conditions, and desired finish quality.

Key Differences Between Wet and Dry Gypsum Methods

Wet gypsum application involves mixing gypsum with water to create a slurry that can be sprayed or spread easily, enhancing soil infiltration and reducing dust. Dry gypsum application delivers finely ground gypsum directly onto the soil surface, allowing for quicker handling but potentially less immediate soil incorporation. The key differences lie in moisture content, application speed, and soil interaction, with wet gypsum promoting faster nutrient availability and dry gypsum offering operational convenience.

Benefits of Wet Gypsum Application

Wet gypsum application enhances soil structure by improving water infiltration and reducing surface runoff, leading to better moisture retention and root development. It promotes faster nutrient absorption and minimizes dust generation compared to dry applications, ensuring more efficient and environmentally friendly delivery. This method is particularly effective for correcting soil acidity and reclaiming sodic soils in agricultural practices.

Advantages of Dry Gypsum Application

Dry gypsum application offers precise nutrient delivery, minimizing soil runoff and enhancing crop uptake efficiency. This method enables easy storage and handling, reducing labor costs and application time in large-scale agricultural operations. Furthermore, dry gypsum improves soil structure by increasing calcium availability without causing soil compaction or moisture-related issues common in wet applications.

Common Uses of Wet Gypsum in Construction

Wet gypsum is commonly applied as a plaster or stucco in construction for interior wall finishes and ceiling coatings, providing smooth, fire-resistant surfaces. It is favored for its ease of molding and ability to create seamless joints, making it ideal for decorative elements and detailed architectural features. The moisture content in wet gypsum enhances workability, allowing for faster application and better adhesion compared to dry gypsum products.

Typical Applications for Dry Gypsum Products

Dry gypsum products are commonly used in wallboard, ceiling tiles, and plasterboard applications due to their ease of handling and quick installation. These products provide structural support, fire resistance, and improved sound insulation in residential and commercial buildings. The versatility of dry gypsum boards allows for efficient interior finishing with minimal moisture-related issues.

Cost Comparison: Wet vs Dry Gypsum

Wet gypsum application generally incurs higher initial costs due to the need for specialized spraying equipment and increased labor, while dry gypsum application tends to have lower upfront expenses because it can be broadcast using common farming tools. However, wet gypsum can offer improved soil penetration and faster nutrient availability, potentially reducing long-term soil amendment costs. In contrast, dry gypsum requires multiple applications over time, which may increase cumulative expenses despite lower initial investment.

Installation Process for Wet Gypsum

Wet gypsum application involves mixing gypsum powder with water to create a slurry that is applied directly to surfaces using trowels or spray machines, allowing for smooth and seamless finishes. This installation process requires careful control of water-to-gypsum ratios to ensure optimal setting times and durability, with drying periods that vary depending on environmental conditions. Unlike dry gypsum application, wet methods enable easier manipulation for complex architectural designs and better adhesion on uneven substrates.

Steps for Dry Gypsum Application

Dry gypsum application involves first preparing the soil by ensuring it is dry and crumbly to allow proper gypsum incorporation. The next step is to uniformly spread the gypsum in its powdered or granular form using mechanical spreaders or by hand for smaller areas. Finally, light tillage or irrigation is applied to help the gypsum penetrate the soil profile, improving calcium availability and reducing soil compaction.

Choosing the Right Gypsum Method for Your Project

Selecting the appropriate gypsum application method depends on project specifications, environmental conditions, and desired finish quality. Wet gypsum application offers smoother surfaces and faster adhesion, ideal for interior walls and ceilings, while dry gypsum is better suited for quick installations and repairs with minimal water use. Evaluating factors such as drying time, labor intensity, and material cost ensures efficient and effective gypsum application tailored to project needs.

Wet gypsum application vs Dry gypsum application Infographic

materialdif.com

materialdif.com