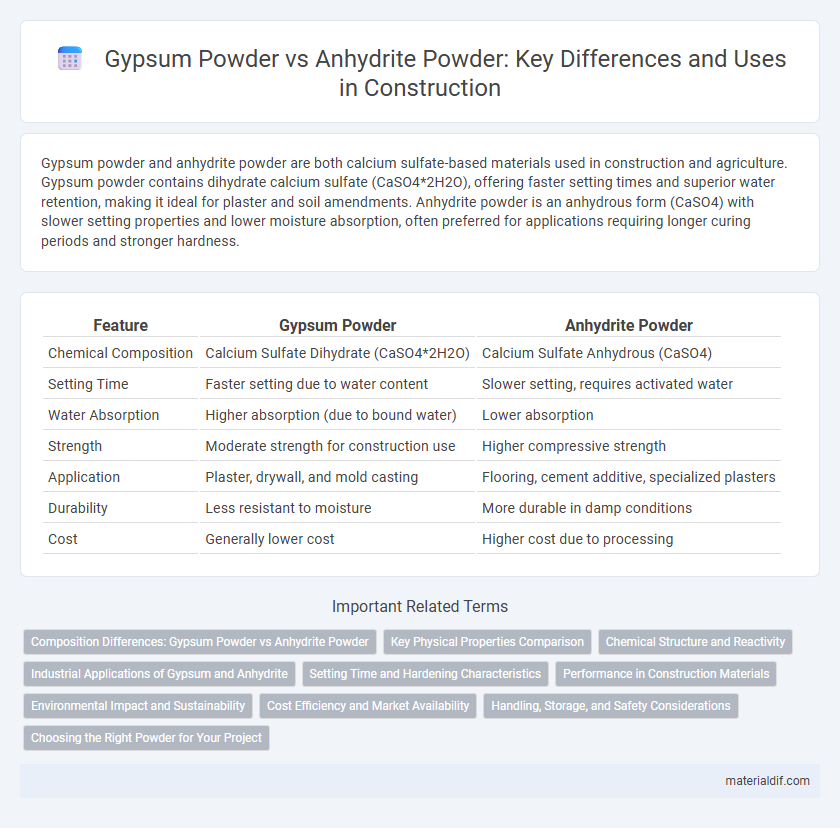

Gypsum powder and anhydrite powder are both calcium sulfate-based materials used in construction and agriculture. Gypsum powder contains dihydrate calcium sulfate (CaSO4*2H2O), offering faster setting times and superior water retention, making it ideal for plaster and soil amendments. Anhydrite powder is an anhydrous form (CaSO4) with slower setting properties and lower moisture absorption, often preferred for applications requiring longer curing periods and stronger hardness.

Table of Comparison

| Feature | Gypsum Powder | Anhydrite Powder |

|---|---|---|

| Chemical Composition | Calcium Sulfate Dihydrate (CaSO4*2H2O) | Calcium Sulfate Anhydrous (CaSO4) |

| Setting Time | Faster setting due to water content | Slower setting, requires activated water |

| Water Absorption | Higher absorption (due to bound water) | Lower absorption |

| Strength | Moderate strength for construction use | Higher compressive strength |

| Application | Plaster, drywall, and mold casting | Flooring, cement additive, specialized plasters |

| Durability | Less resistant to moisture | More durable in damp conditions |

| Cost | Generally lower cost | Higher cost due to processing |

Composition Differences: Gypsum Powder vs Anhydrite Powder

Gypsum powder primarily consists of calcium sulfate dihydrate (CaSO4*2H2O), which contains two molecules of water chemically bound to each calcium sulfate unit, providing its characteristic softness and ease of handling. In contrast, anhydrite powder is composed of calcium sulfate anhydrous (CaSO4), lacking water molecules, resulting in a denser and harder material with slower setting times. The compositional difference impacts their hydration behavior, solubility, and applications, with gypsum favoring rapid setting in construction and anhydrite being preferred in specialized industrial processes.

Key Physical Properties Comparison

Gypsum powder, primarily composed of calcium sulfate dihydrate, exhibits excellent water retention and sets rapidly upon mixing with water, making it ideal for construction and plaster applications. Anhydrite powder, consisting of calcium sulfate anhydrous, features lower water demand and slower setting times but offers higher compressive strength and improved dimensional stability. The particle size distribution and hardness differences between gypsum and anhydrite powders critically influence their respective handling characteristics and suitability for specific industrial uses.

Chemical Structure and Reactivity

Gypsum powder primarily consists of calcium sulfate dihydrate (CaSO4*2H2O), exhibiting higher reactivity due to its water molecules facilitating rapid hydration and setting in construction applications. Anhydrite powder, composed of anhydrous calcium sulfate (CaSO4), has a denser crystalline structure with lower chemical reactivity, leading to slower hydration and longer setting times. The presence of water molecules in gypsum powder enhances its chemical reactivity compared to the more stable and less reactive anhydrite powder.

Industrial Applications of Gypsum and Anhydrite

Gypsum powder and anhydrite powder serve distinct industrial applications based on their hydration properties and mineral composition, with gypsum widely used in the construction industry for drywall, plaster, and cement additives due to its ability to set quickly and improve workability. Anhydrite powder finds applications in the production of anhydrite plaster, soil stabilization, and as a drying agent in industrial processes because it offers slow-setting characteristics and higher sulfate content. Both minerals are crucial in cement manufacturing for controlling setting times and enhancing strength, but gypsum's faster hydration makes it preferred in rapid construction projects.

Setting Time and Hardening Characteristics

Gypsum powder sets faster due to its higher reactivity and contains more water molecules in its crystalline structure, promoting rapid hydration and initial hardening. Anhydrite powder exhibits slower setting times because it lacks bound water, leading to gradual water absorption and longer hydration phases. The hardening characteristics of gypsum result in a more brittle finish, while anhydrite provides denser and stronger end strength suitable for applications requiring prolonged setting periods.

Performance in Construction Materials

Gypsum powder offers superior workability and faster setting times compared to anhydrite powder, making it ideal for applications requiring quick strength development in construction materials. Anhydrite powder provides enhanced dimensional stability and lower shrinkage due to its slower hydration process, which improves the durability of plaster and screed systems. Both materials contribute to improved fire resistance and sound insulation, but selection depends on the specific performance requirements of the construction project.

Environmental Impact and Sustainability

Gypsum powder, derived from natural gypsum, typically has lower environmental impact due to its abundant availability and minimal processing requirements compared to anhydrite powder, which demands higher energy for production through calcination. Anhydrite powder's induced energy consumption results in increased carbon emissions, making gypsum powder a more sustainable choice for construction and agricultural applications. Recycling gypsum from industrial by-products further enhances environmental benefits by reducing raw material extraction and waste generation.

Cost Efficiency and Market Availability

Gypsum powder offers greater cost efficiency due to its abundant natural reserves and simpler processing methods compared to anhydrite powder, which requires higher energy inputs for production. Market availability of gypsum powder is significantly higher globally, driven by its widespread use in construction and agriculture. Anhydrite powder, though valued for specialized applications, remains less accessible and often commands a premium price due to limited supply and more complex extraction processes.

Handling, Storage, and Safety Considerations

Gypsum powder requires careful storage in dry, well-ventilated areas to prevent moisture absorption, while anhydrite powder is less hygroscopic but still demands protection from humidity to maintain quality. Both materials should be handled with protective gear, including masks and gloves, to avoid respiratory irritation and skin contact due to fine particulate matter. Fire safety measures are essential since both powders are non-combustible but can create dust explosions in confined spaces if not properly controlled.

Choosing the Right Powder for Your Project

Gypsum powder, known for its faster setting time and higher water retention, is ideal for indoor applications like drywall and plaster repairs requiring smooth finishes. Anhydrite powder, with its slower hydration and superior hardness, is preferred in flooring and large-scale construction projects where durability and minimal shrinkage are critical. Understanding the specific setting properties and moisture requirements of your project ensures optimal performance and longevity when selecting between gypsum and anhydrite powders.

Gypsum powder vs Anhydrite powder Infographic

materialdif.com

materialdif.com