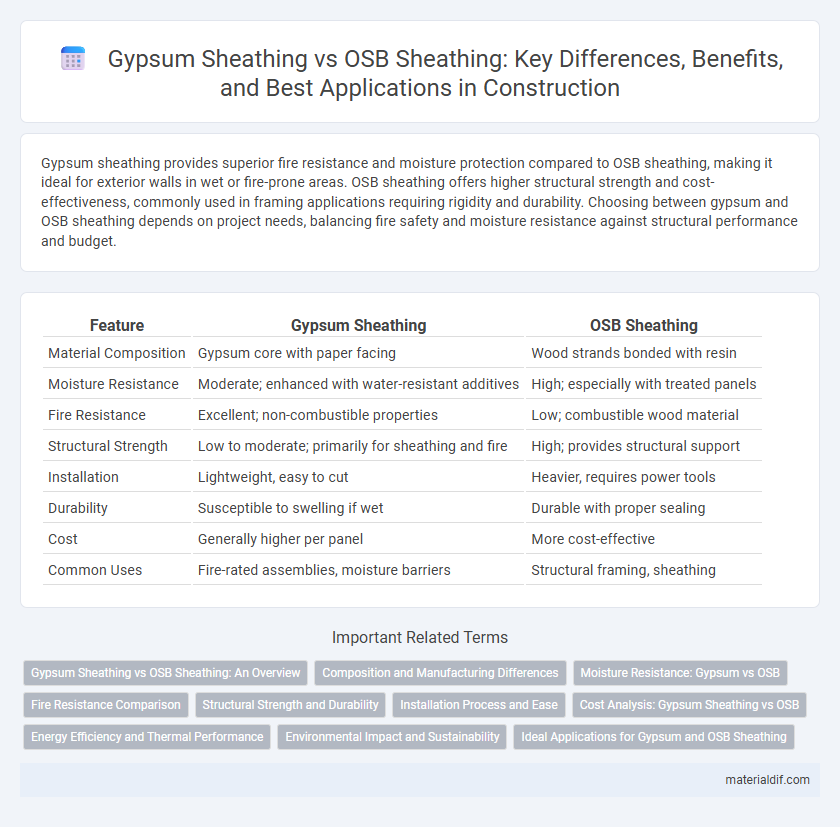

Gypsum sheathing provides superior fire resistance and moisture protection compared to OSB sheathing, making it ideal for exterior walls in wet or fire-prone areas. OSB sheathing offers higher structural strength and cost-effectiveness, commonly used in framing applications requiring rigidity and durability. Choosing between gypsum and OSB sheathing depends on project needs, balancing fire safety and moisture resistance against structural performance and budget.

Table of Comparison

| Feature | Gypsum Sheathing | OSB Sheathing |

|---|---|---|

| Material Composition | Gypsum core with paper facing | Wood strands bonded with resin |

| Moisture Resistance | Moderate; enhanced with water-resistant additives | High; especially with treated panels |

| Fire Resistance | Excellent; non-combustible properties | Low; combustible wood material |

| Structural Strength | Low to moderate; primarily for sheathing and fire | High; provides structural support |

| Installation | Lightweight, easy to cut | Heavier, requires power tools |

| Durability | Susceptible to swelling if wet | Durable with proper sealing |

| Cost | Generally higher per panel | More cost-effective |

| Common Uses | Fire-rated assemblies, moisture barriers | Structural framing, sheathing |

Gypsum Sheathing vs OSB Sheathing: An Overview

Gypsum sheathing offers superior fire resistance and moisture resistance compared to OSB sheathing, making it ideal for exterior wall applications where durability against weather and fire is critical. OSB sheathing provides higher structural strength and stiffness, enhancing overall wall system performance in load-bearing scenarios. Selecting between gypsum and OSB sheathing depends on project-specific requirements such as fire protection, moisture exposure, and structural needs.

Composition and Manufacturing Differences

Gypsum sheathing consists primarily of gypsum plaster pressed between fiberglass mats, offering superior fire resistance and moisture control, while oriented strand board (OSB) is made from compressed wood strands bonded with synthetic resins, providing high structural strength. The manufacturing of gypsum sheathing involves hydrating gypsum to form a dense core bound by fiberglass, whereas OSB production uses wood strands layered in specific orientations and bonded under heat and pressure. These fundamental composition and manufacturing differences influence their performance in terms of durability, water resistance, and suitability for various building applications.

Moisture Resistance: Gypsum vs OSB

Gypsum sheathing offers superior moisture resistance compared to OSB sheathing due to its water-resistant core and ability to delay water penetration, reducing the risk of mold and structural damage. OSB, being wood-based, is more susceptible to moisture absorption, swelling, and degradation when exposed to prolonged wet conditions. This makes gypsum sheathing a preferred choice in areas prone to high humidity or water exposure, enhancing durability and building envelope protection.

Fire Resistance Comparison

Gypsum sheathing exhibits superior fire resistance compared to OSB sheathing due to its non-combustible properties and ability to slow heat transfer during fire exposure. The calcium sulfate dihydrate composition in gypsum provides a natural fire barrier, delaying flame spread and structural damage. In contrast, OSB sheathing, made of compressed wood strands, ignites and burns more readily, leading to faster structural compromise in fire scenarios.

Structural Strength and Durability

Gypsum sheathing offers superior fire resistance and moisture resistance compared to OSB sheathing, which enhances its durability in harsh environments. OSB provides greater structural strength and load-bearing capacity due to its composition from wood strands bound with adhesives, making it ideal for framing and roof decking. Gypsum sheathing's resistance to mold and rot contributes to long-term durability, while OSB requires proper sealing to prevent water damage and swelling.

Installation Process and Ease

Gypsum sheathing offers a straightforward installation process due to its lightweight panels and easy cutting with standard tools, reducing labor time compared to OSB sheathing, which often requires more effort to handle and fasten securely. Gypsum panels are less prone to splintering, allowing for cleaner edges and easier fitting around openings, whereas OSB sheathing can produce rough edges and demands more precise alignment to prevent structural gaps. The moisture-resistant properties of gypsum sheathing also improve installation efficiency by minimizing warping and swelling, common challenges when working with OSB in damp conditions.

Cost Analysis: Gypsum Sheathing vs OSB

Gypsum sheathing generally has a higher upfront cost compared to OSB sheathing but offers superior fire resistance and moisture tolerance, potentially reducing long-term repair and insurance expenses. OSB sheathing is more affordable initially, making it a popular choice for budget-conscious projects, though it may require additional waterproofing measures that increase overall costs. Evaluating total lifecycle costs, including durability, maintenance, and insurance implications, is essential when choosing between gypsum and OSB sheathing for construction.

Energy Efficiency and Thermal Performance

Gypsum sheathing offers superior fire resistance and moisture control, enhancing overall energy efficiency by maintaining stable indoor temperatures and reducing HVAC load. Oriented Strand Board (OSB) sheathing provides structural strength but is more susceptible to moisture infiltration, which can compromise thermal performance over time. The insulating properties of gypsum contribute to improved thermal performance, making it a preferred choice for energy-efficient building envelopes.

Environmental Impact and Sustainability

Gypsum sheathing offers a more environmentally sustainable option compared to OSB sheathing due to its non-toxic composition and recyclability, reducing landfill waste. It provides excellent moisture resistance and fire retardancy without relying on formaldehyde-based adhesives common in OSB, enhancing indoor air quality and reducing harmful emissions. Additionally, gypsum's mineral-based nature results in lower embodied energy and promotes circular economy practices in construction.

Ideal Applications for Gypsum and OSB Sheathing

Gypsum sheathing is ideal for exterior walls in residential and commercial buildings where fire resistance and moisture control are critical, providing a non-combustible barrier that enhances structural safety. OSB sheathing, made from compressed wood strands, is best suited for roof decking and wall sheathing in load-bearing applications due to its high strength and rigidity. Choosing gypsum over OSB is beneficial in areas prone to mold or requiring enhanced fire ratings, while OSB serves well in framing projects demanding durability and cost-effectiveness.

Gypsum sheathing vs OSB sheathing Infographic

materialdif.com

materialdif.com