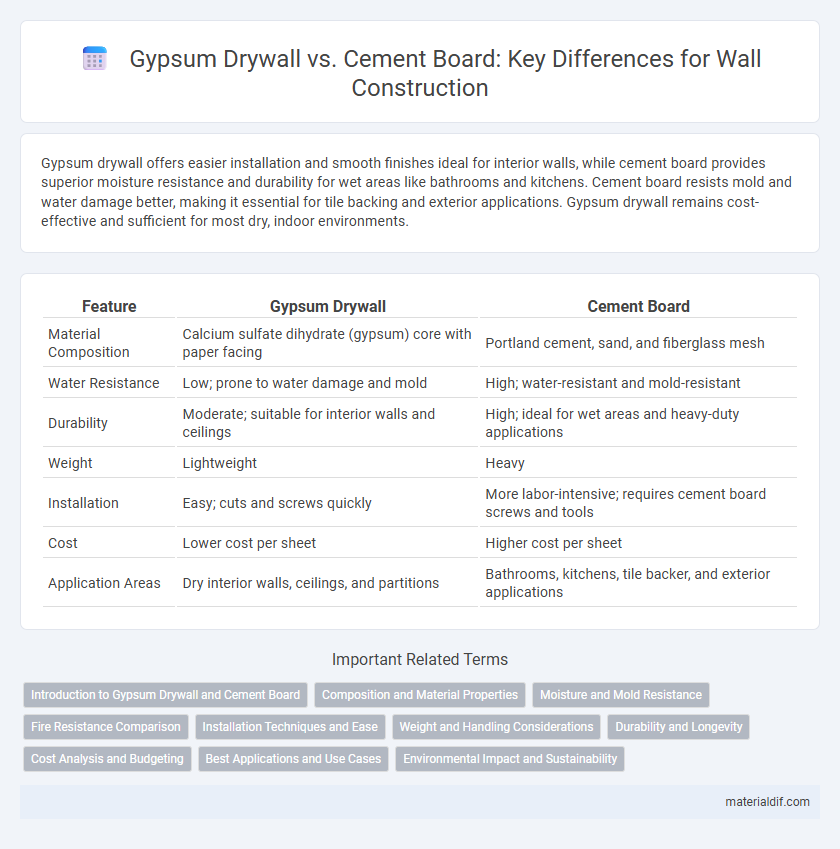

Gypsum drywall offers easier installation and smooth finishes ideal for interior walls, while cement board provides superior moisture resistance and durability for wet areas like bathrooms and kitchens. Cement board resists mold and water damage better, making it essential for tile backing and exterior applications. Gypsum drywall remains cost-effective and sufficient for most dry, indoor environments.

Table of Comparison

| Feature | Gypsum Drywall | Cement Board |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate (gypsum) core with paper facing | Portland cement, sand, and fiberglass mesh |

| Water Resistance | Low; prone to water damage and mold | High; water-resistant and mold-resistant |

| Durability | Moderate; suitable for interior walls and ceilings | High; ideal for wet areas and heavy-duty applications |

| Weight | Lightweight | Heavy |

| Installation | Easy; cuts and screws quickly | More labor-intensive; requires cement board screws and tools |

| Cost | Lower cost per sheet | Higher cost per sheet |

| Application Areas | Dry interior walls, ceilings, and partitions | Bathrooms, kitchens, tile backer, and exterior applications |

Introduction to Gypsum Drywall and Cement Board

Gypsum drywall consists of a gypsum core sandwiched between paper layers, providing a smooth, easy-to-install surface commonly used for interior walls and ceilings. Cement board, made from cement and reinforcing fibers, offers superior moisture resistance and durability, making it ideal for wet areas like bathrooms and kitchens. Both materials serve as essential substrates in construction, with gypsum drywall favored for general applications and cement board preferred for moisture-prone environments.

Composition and Material Properties

Gypsum drywall is primarily composed of a gypsum core sandwiched between paper facings, offering excellent fire resistance, sound insulation, and ease of installation due to its lightweight and smooth surface. Cement board consists of a mixture of cement and reinforcing fibers, which provides superior moisture resistance, durability, and strength, making it ideal for wet areas like bathrooms and kitchens. While gypsum drywall excels in indoor applications with low moisture exposure, cement board is preferred for high-moisture environments due to its dense, non-porous composition and resistance to mold and mildew.

Moisture and Mold Resistance

Gypsum drywall is susceptible to moisture damage and mold growth due to its paper-faced core, making it unsuitable for high-humidity areas like bathrooms or basements. Cement board features a non-organic composition with enhanced mold and moisture resistance, providing superior durability in wet environments. Its dense, impermeable structure prevents water absorption, reducing the risk of structural degradation and mold infestation over time.

Fire Resistance Comparison

Gypsum drywall offers standard fire resistance by containing chemically combined water that releases steam when exposed to heat, slowing fire spread. Cement board provides superior fire resistance due to its non-combustible composition made from cement and reinforcing fibers, making it ideal for high-heat areas. Building codes often require cement board in areas prone to moisture and fire, such as kitchens and bathrooms, due to its enhanced durability and fire-resistant properties.

Installation Techniques and Ease

Gypsum drywall offers quicker installation due to its lightweight panels that are easily cut and fastened with screws or nails, reducing labor time and costs. Cement board requires more specialized handling, as it is heavier and typically cut with a carbide-tipped scoring tool, needing corrosion-resistant screws for secure attachment. While gypsum drywall is ideal for standard interior walls, cement board provides superior moisture resistance suitable for tile substrates in wet areas, though its installation demands more effort and precision.

Weight and Handling Considerations

Gypsum drywall is significantly lighter than cement board, making it easier to handle and install, especially for ceiling applications or large wall areas. Cement board's denser composition increases its weight, requiring more effort and often additional labor or tools during installation. The lighter weight of gypsum drywall reduces fatigue and speeds up the construction process, while cement board's durability justifies its heavier handling in moisture-prone environments.

Durability and Longevity

Gypsum drywall offers moderate durability, suitable for interior walls in low-moisture areas, but is prone to damage from impact and water exposure. Cement board provides superior durability and longevity, resisting moisture, mold, and physical damage, making it ideal for high-humidity environments like bathrooms and kitchens. Choosing cement board over gypsum drywall ensures enhanced structural integrity and a longer lifespan in demanding applications.

Cost Analysis and Budgeting

Gypsum drywall generally costs between $10 and $15 per sheet, making it a budget-friendly option for interior walls with quick installation and ease of finishing. Cement board, priced around $20 to $30 per sheet, offers higher durability and moisture resistance, ideal for wet areas but results in increased material and labor expenses. Budget planning for construction projects should weigh these cost differences against project requirements, considering gypsum's affordability versus cement board's longevity and resistance benefits.

Best Applications and Use Cases

Gypsum drywall excels in interior applications such as residential walls and ceilings due to its ease of installation, smooth finish, and affordability, making it ideal for dry environments and standard living spaces. Cement board is preferred in wet or high-moisture areas like bathrooms, kitchens, and exterior walls because of its superior water resistance, durability, and mold resistance. Combining both materials optimizes building performance by using gypsum drywall in dry zones and cement board in moisture-prone areas to extend surface longevity and maintain structural integrity.

Environmental Impact and Sustainability

Gypsum drywall offers lower embodied energy and is recyclable, making it a more sustainable choice compared to cement board, which requires energy-intensive production and is less frequently recycled. Cement board, while more durable and moisture-resistant, contributes to higher carbon emissions due to cement manufacturing processes. Selecting gypsum drywall can reduce environmental impact through its use of abundant natural gypsum and lower waste generation.

Gypsum drywall vs Cement board Infographic

materialdif.com

materialdif.com