FGD gypsum is a byproduct of flue gas desulfurization in power plants, offering a purer, more consistent chemical composition than natural gypsum, which is mined from geological deposits. It contains fewer impurities and has finer particle size, making it highly suitable for use in the construction industry, especially in drywall and cement production. The sustainable advantage of FGD gypsum lies in its role as a recycled material that reduces environmental impact compared to the extraction of natural gypsum.

Table of Comparison

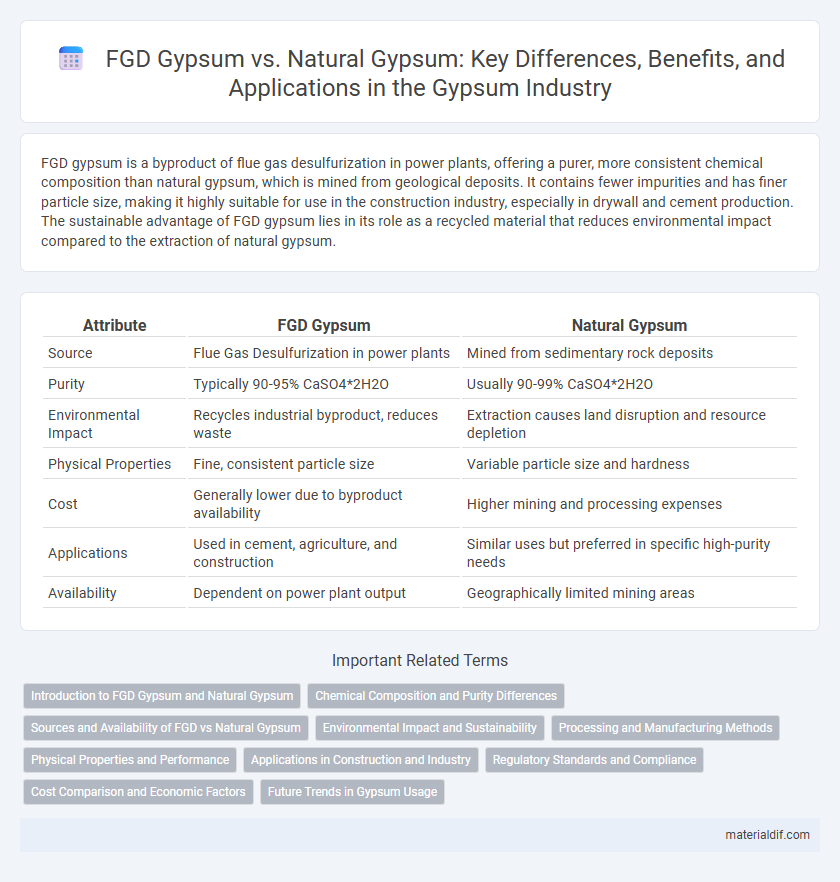

| Attribute | FGD Gypsum | Natural Gypsum |

|---|---|---|

| Source | Flue Gas Desulfurization in power plants | Mined from sedimentary rock deposits |

| Purity | Typically 90-95% CaSO4*2H2O | Usually 90-99% CaSO4*2H2O |

| Environmental Impact | Recycles industrial byproduct, reduces waste | Extraction causes land disruption and resource depletion |

| Physical Properties | Fine, consistent particle size | Variable particle size and hardness |

| Cost | Generally lower due to byproduct availability | Higher mining and processing expenses |

| Applications | Used in cement, agriculture, and construction | Similar uses but preferred in specific high-purity needs |

| Availability | Dependent on power plant output | Geographically limited mining areas |

Introduction to FGD Gypsum and Natural Gypsum

FGD gypsum, a byproduct of flue gas desulfurization in power plants, offers high purity and consistent quality compared to natural gypsum, which is mined directly from sedimentary deposits. Natural gypsum contains varying levels of impurities such as clay and organic material, affecting its suitability for certain industrial applications. The controlled production of FGD gypsum ensures a reliable supply for use in construction materials, soil amendment, and cement manufacturing.

Chemical Composition and Purity Differences

FGD gypsum, a byproduct of flue gas desulfurization in power plants, contains higher purity levels of calcium sulfate dihydrate (CaSO4*2H2O) compared to natural gypsum, which often includes impurities such as quartz, clay, and other minerals. The chemical composition of FGD gypsum is typically more consistent, with purity levels exceeding 90-95%, whereas natural gypsum purity can vary widely, often ranging from 70-90%. This higher purity and uniform chemical composition make FGD gypsum preferable for applications requiring precise chemical properties, such as in the cement and wallboard industries.

Sources and Availability of FGD vs Natural Gypsum

FGD gypsum is derived as a byproduct from flue gas desulfurization in coal-fired power plants, offering a more sustainable and consistent supply compared to natural gypsum, which is mined directly from sedimentary rock deposits formed over millions of years. Availability of FGD gypsum depends on industrial activity and regulatory policies on emissions, while natural gypsum extraction is subject to geological constraints and environmental considerations. The widespread use of FGD gypsum in construction and agriculture addresses the limitations of natural gypsum availability and helps reduce waste from power generation.

Environmental Impact and Sustainability

FGD gypsum, a byproduct of flue gas desulfurization in coal-fired power plants, offers environmental benefits by recycling industrial waste that would otherwise contribute to landfill and air pollution. Unlike natural gypsum, which requires mining and causes habitat disruption, FGD gypsum reduces the depletion of natural resources and lowers carbon emissions associated with extraction processes. Utilizing FGD gypsum supports sustainability by promoting circular economy principles and minimizing environmental degradation.

Processing and Manufacturing Methods

FGD gypsum is produced through the flue gas desulfurization process in power plants, capturing sulfur dioxide emissions and converting them into synthetic gypsum, which requires purification and drying before use. Natural gypsum is mined directly from sedimentary deposits, then crushed, ground, and sometimes calcined to remove moisture and impurities for industrial applications. The manufacturing of FGD gypsum involves chemical processing steps, whereas natural gypsum relies primarily on mechanical processing.

Physical Properties and Performance

FGD gypsum, derived from flue gas desulfurization, has a finer particle size and higher purity compared to natural gypsum, resulting in improved setting times and strength development in construction applications. Its consistent chemical composition enhances hydration and reduces variability in performance, making it preferable for high-quality drywall and cement production. Natural gypsum contains impurities and coarser particles, which can affect uniformity and durability in finished products.

Applications in Construction and Industry

FGD gypsum, a byproduct of flue gas desulfurization in coal-fired power plants, offers a high-purity alternative to natural gypsum with consistent quality ideal for manufacturing drywall, cement, and plaster products. Its controlled particle size and low impurity levels enhance the strength and durability of construction materials compared to natural gypsum extracted from quarries. Both types serve key roles in agriculture and industry, but FGD gypsum's eco-friendly sourcing supports sustainable building practices by recycling industrial waste.

Regulatory Standards and Compliance

FGD gypsum, a byproduct of flue gas desulfurization in coal-fired power plants, must meet stringent regulatory standards concerning purity and heavy metal content to ensure safe use in agriculture and construction. Natural gypsum, mined from geological deposits, typically complies with established environmental regulations but faces stricter scrutiny due to potential impurities and varying mineral content. Compliance with EPA guidelines and ASTM standards is crucial for both types to minimize environmental impact and guarantee material quality in applications.

Cost Comparison and Economic Factors

FGD gypsum, produced as a byproduct of flue gas desulfurization in coal-fired power plants, generally offers a cost advantage over natural gypsum due to its lower raw material and extraction expenses. Economic factors favor FGD gypsum for construction and agricultural uses because processing and transportation costs tend to be reduced, given its proximity to industrial sources. However, price fluctuations and availability of natural gypsum in certain regions can influence the overall cost competitiveness between the two.

Future Trends in Gypsum Usage

Future trends in gypsum usage emphasize the increasing preference for FGD gypsum due to its sustainable properties and consistency in quality compared to natural gypsum. Advancements in flue gas desulfurization technology enhance the production efficiency of FGD gypsum, making it a viable alternative for construction materials and agriculture. The growing regulatory pressure to reduce industrial emissions further accelerates the demand and innovation in recycling FGD gypsum, positioning it as a critical resource in circular economy models.

FGD gypsum vs Natural gypsum Infographic

materialdif.com

materialdif.com