Gypsum fiber board offers superior fire resistance and sound insulation compared to OSB (Oriented Strand Board), making it ideal for interior walls and ceilings. OSB provides higher structural strength and moisture resistance, which benefits exterior sheathing and load-bearing applications. Choosing between the two depends on specific project requirements such as durability, environmental exposure, and fire safety standards.

Table of Comparison

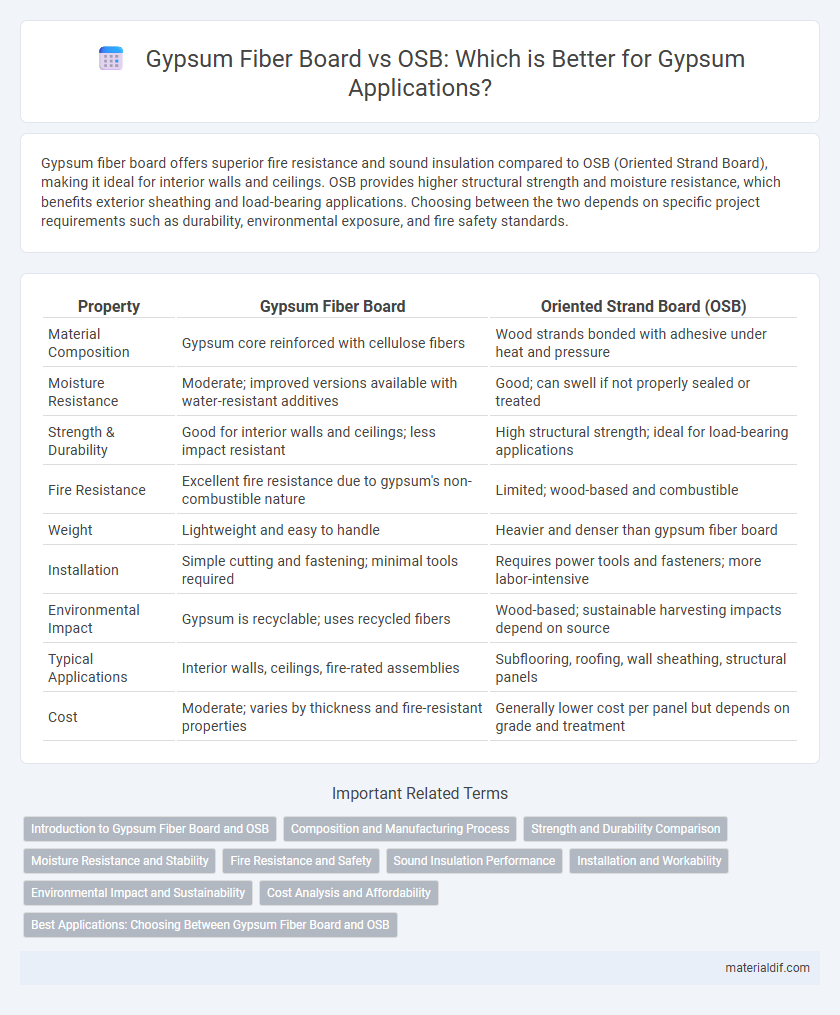

| Property | Gypsum Fiber Board | Oriented Strand Board (OSB) |

|---|---|---|

| Material Composition | Gypsum core reinforced with cellulose fibers | Wood strands bonded with adhesive under heat and pressure |

| Moisture Resistance | Moderate; improved versions available with water-resistant additives | Good; can swell if not properly sealed or treated |

| Strength & Durability | Good for interior walls and ceilings; less impact resistant | High structural strength; ideal for load-bearing applications |

| Fire Resistance | Excellent fire resistance due to gypsum's non-combustible nature | Limited; wood-based and combustible |

| Weight | Lightweight and easy to handle | Heavier and denser than gypsum fiber board |

| Installation | Simple cutting and fastening; minimal tools required | Requires power tools and fasteners; more labor-intensive |

| Environmental Impact | Gypsum is recyclable; uses recycled fibers | Wood-based; sustainable harvesting impacts depend on source |

| Typical Applications | Interior walls, ceilings, fire-rated assemblies | Subflooring, roofing, wall sheathing, structural panels |

| Cost | Moderate; varies by thickness and fire-resistant properties | Generally lower cost per panel but depends on grade and treatment |

Introduction to Gypsum Fiber Board and OSB

Gypsum fiber board combines gypsum with cellulose fibers, offering enhanced fire resistance, sound insulation, and durability compared to traditional boards. Oriented Strand Board (OSB) consists of compressed wood strands arranged in layers, providing structural strength and cost-effectiveness primarily for sheathing and subflooring. Each material serves distinct construction needs, with gypsum fiber board excelling in interior applications requiring moisture and fire resistance, while OSB is favored for load-bearing structural components.

Composition and Manufacturing Process

Gypsum fiber board is composed primarily of gypsum crystals combined with cellulose fibers, providing enhanced fire resistance and sound insulation properties. Its manufacturing process involves mixing gypsum slurry with natural fibers followed by board formation and drying under controlled conditions. OSB is produced by compressing layers of wood strands with adhesives in specific orientations, resulting in a strong, moisture-resistant panel used predominantly in structural applications.

Strength and Durability Comparison

Gypsum fiber board offers superior fire resistance and moisture stability compared to OSB, making it a durable choice for interior applications. OSB exhibits higher structural strength and load-bearing capacity, suitable for subflooring and wall sheathing in construction. Both materials provide durability, but gypsum fiber board excels in moisture-prone environments, while OSB performs better under heavy load stresses.

Moisture Resistance and Stability

Gypsum fiber board offers superior moisture resistance compared to OSB due to its dense, non-porous composition that minimizes water absorption and inhibits mold growth. OSB, made from wood strands and adhesives, is more susceptible to moisture damage, swelling, and deformation over time when exposed to high humidity or water. The inherent stability of gypsum fiber board under moist conditions makes it a preferred choice for areas prone to dampness, ensuring long-term structural integrity and durability.

Fire Resistance and Safety

Gypsum fiber board offers superior fire resistance compared to OSB (Oriented Strand Board) due to its non-combustible core and ability to release water vapor when exposed to heat, slowing fire spread. OSB, made from wood strands bonded with adhesives, is more combustible and less effective at containing flames. Gypsum fiber board enhances safety in building applications by meeting stringent fire-rated construction standards, making it an ideal choice for fire-resistant walls and ceilings.

Sound Insulation Performance

Gypsum fiber board offers superior sound insulation performance compared to OSB (Oriented Strand Board) due to its dense composition and ability to absorb sound waves effectively. The high mass and fibrous structure of gypsum fiber board reduce airborne noise transmission, making it ideal for interior walls and ceilings in acoustic-sensitive environments. OSB, being less dense and rigid, provides minimal sound dampening, which can result in higher noise transfer between rooms.

Installation and Workability

Gypsum fiber board offers easier cutting and shaping compared to OSB, reducing installation time for complex designs. Its lightweight nature improves handling and fastening, while OSB requires specialized tools due to its density and composition. Gypsum fiber board's smoother surface enhances finishing quality, making it preferable in detailed interior applications.

Environmental Impact and Sustainability

Gypsum fiber board offers superior environmental benefits compared to OSB due to its non-toxic composition, recyclability, and production from abundant, naturally occurring gypsum minerals that reduce reliance on wood resources. OSB, while made from wood strands, involves adhesives and resins that can emit volatile organic compounds (VOCs) and contribute to deforestation if not sourced sustainably. The lifecycle analysis of gypsum fiber board demonstrates lower carbon emissions and enhanced recyclability, making it a more sustainable choice for eco-conscious construction projects.

Cost Analysis and Affordability

Gypsum fiber board generally offers higher fire resistance and acoustic insulation at a slightly higher cost compared to OSB, which is typically more affordable due to its cost-effective manufacturing process using wood strands. OSB is favored in budget-conscious construction projects for its lower price per square foot and ease of installation, while gypsum fiber board, despite higher initial costs, may reduce long-term expenses through improved durability and mold resistance. Cost analysis reveals that the choice between gypsum fiber board and OSB depends on balancing upfront material costs with potential lifecycle savings and specific performance requirements.

Best Applications: Choosing Between Gypsum Fiber Board and OSB

Gypsum fiber board excels in fire resistance and sound insulation, making it ideal for interior walls and ceilings in residential and commercial buildings where safety and acoustic performance are priorities. OSB (Oriented Strand Board) offers superior structural strength and moisture resistance, suited for subflooring, roofing, and exterior wall sheathing in construction projects requiring durability and load-bearing capacity. Selecting between gypsum fiber board and OSB depends on specific application needs such as fire rating, moisture environment, and structural demands.

Gypsum fiber board vs OSB (Oriented Strand Board) Infographic

materialdif.com

materialdif.com