Gypsum powder is the raw material derived from natural gypsum stone, whereas Plaster of Paris (POP) is produced by heating gypsum powder to remove water content, resulting in a fine white powder used for casting and molding. Gypsum powder retains moisture and is commonly used in agriculture and construction for soil conditioning, while POP is preferred for its quick-setting properties in decorative and medical applications. The key difference lies in their production process and usage, with POP offering faster hardening and smoother finishes compared to raw gypsum powder.

Table of Comparison

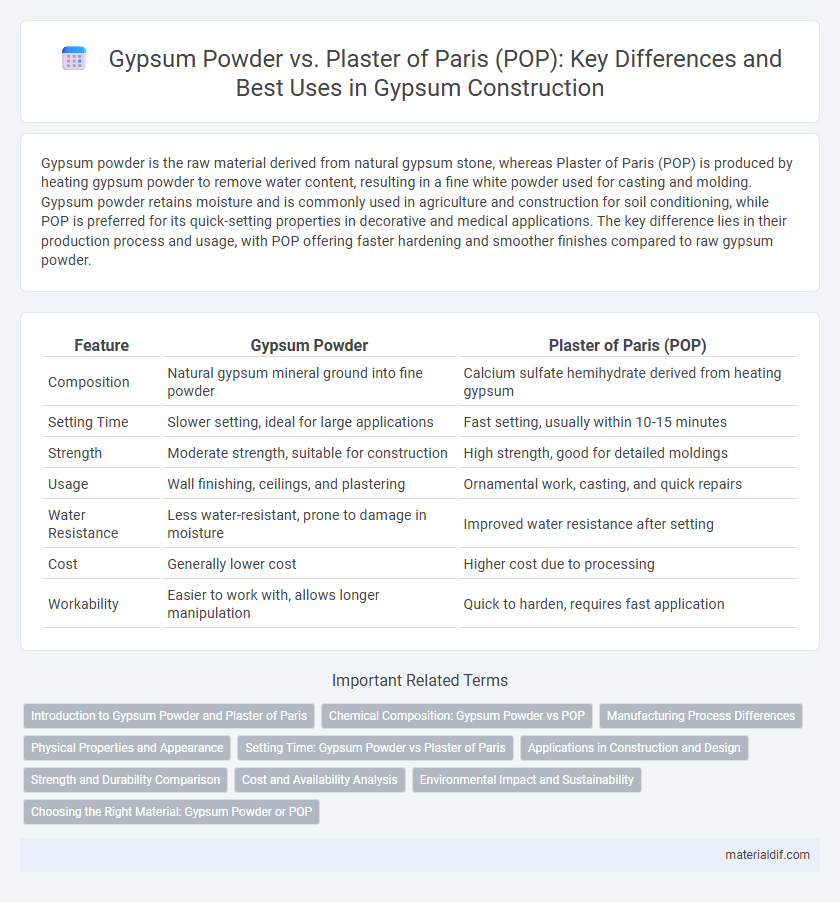

| Feature | Gypsum Powder | Plaster of Paris (POP) |

|---|---|---|

| Composition | Natural gypsum mineral ground into fine powder | Calcium sulfate hemihydrate derived from heating gypsum |

| Setting Time | Slower setting, ideal for large applications | Fast setting, usually within 10-15 minutes |

| Strength | Moderate strength, suitable for construction | High strength, good for detailed moldings |

| Usage | Wall finishing, ceilings, and plastering | Ornamental work, casting, and quick repairs |

| Water Resistance | Less water-resistant, prone to damage in moisture | Improved water resistance after setting |

| Cost | Generally lower cost | Higher cost due to processing |

| Workability | Easier to work with, allows longer manipulation | Quick to harden, requires fast application |

Introduction to Gypsum Powder and Plaster of Paris

Gypsum powder is a natural mineral composed of calcium sulfate dihydrate, widely used in construction for its fire-resistant and moisture-regulating properties. Plaster of Paris (POP) is a synthetic material derived from heating gypsum to remove water content, resulting in a fast-setting powder ideal for molding and finishing surfaces. While both materials originate from gypsum, gypsum powder retains its natural composition, whereas POP undergoes processing for enhanced workability and rapid setting.

Chemical Composition: Gypsum Powder vs POP

Gypsum powder primarily consists of calcium sulfate dihydrate (CaSO4*2H2O), while Plaster of Paris (POP) is produced by heating gypsum to remove water molecules, resulting in calcium sulfate hemihydrate (CaSO4*0.5H2O). This chemical transformation in POP enables rapid setting and hardening upon mixing with water, distinguishing its practical use from raw gypsum powder. The hydrated form in gypsum powder offers slower setting properties, suitable for applications requiring extended workability.

Manufacturing Process Differences

Gypsum powder is produced by heating natural gypsum minerals at a controlled temperature to remove water content, resulting in a fine, white powder with minimal chemical alteration. Plaster of Paris (POP) undergoes a higher temperature process known as calcination, where gypsum is heated to approximately 150degC to 170degC, driving off crystalline water and transforming it into a hemi-hydrate form. This difference in manufacturing leads to POP having quicker setting properties and a more reactive chemical composition compared to regular gypsum powder.

Physical Properties and Appearance

Gypsum powder is a naturally occurring mineral composed primarily of calcium sulfate dihydrate, featuring a fine, soft texture and off-white to light gray color, making it ideal for construction and agricultural uses. Plaster of Paris (POP) is derived by heating gypsum to remove water, resulting in a white, fine powder that sets quickly when mixed with water and hardens into a smooth, durable surface. Compared to gypsum powder, POP has higher setting strength and faster drying time but lacks the moisture control properties and slight flexibility of natural gypsum powder.

Setting Time: Gypsum Powder vs Plaster of Paris

Gypsum powder generally exhibits a slower setting time compared to Plaster of Paris (POP), allowing for more extended workability during application. POP sets rapidly, often within 10 to 15 minutes, making it suitable for quick repairs and detailed molding work. The controlled setting time of gypsum powder enhances its usability in construction where precision and longer manipulation are necessary.

Applications in Construction and Design

Gypsum powder, extracted from natural gypsum rock, is widely used in construction for creating durable wall finishes, ceilings, and decorative moldings due to its slow setting time and superior strength. In contrast, Plaster of Paris (POP), derived by heating gypsum to remove water, is favored for rapid setting applications such as creating intricate architectural details and quick repairs. Both materials play crucial roles in interior design, with gypsum powder offering longevity and POP providing versatility in molding and casting tasks.

Strength and Durability Comparison

Gypsum powder and Plaster of Paris (POP) differ significantly in strength and durability, with POP generally offering higher compressive strength and faster setting times due to its chemically processed form. Gypsum powder in its raw state is softer and less dense, resulting in lower durability when used directly in construction applications. For structural uses requiring long-lasting performance, POP is preferred, while pure gypsum powder is more suited for decorative or non-load-bearing finishes.

Cost and Availability Analysis

Gypsum powder is generally more cost-effective and widely available compared to Plaster of Paris (POP), making it a preferred choice for large-scale construction and casting projects. The manufacturing process of gypsum powder involves less energy, contributing to its lower price point and consistent supply in the market. POP, while offering finer texture and quicker setting time, tends to be more expensive and less readily available due to specialized production requirements and higher material costs.

Environmental Impact and Sustainability

Gypsum powder, derived directly from natural gypsum mineral, offers a more sustainable option compared to Plaster of Paris (POP), which undergoes a high-energy calcination process releasing CO2 emissions. Gypsum powder's lower processing requirements result in reduced carbon footprint and energy consumption, promoting eco-friendly construction practices. Additionally, gypsum's recyclability and non-toxic nature contribute to minimizing environmental impact, unlike POP, which can pose disposal challenges due to its chemically altered composition.

Choosing the Right Material: Gypsum Powder or POP

Gypsum powder and Plaster of Paris (POP) are both derived from gypsum but differ in processing and application. Gypsum powder is a raw form used for cement and soil conditioning, while POP is calcined gypsum that sets quickly, making it ideal for detailed moldings and interior finishes. Selecting the right material depends on specific construction needs, such as strength, setting time, and surface finish quality.

Gypsum powder vs POP (Plaster of Paris) Infographic

materialdif.com

materialdif.com