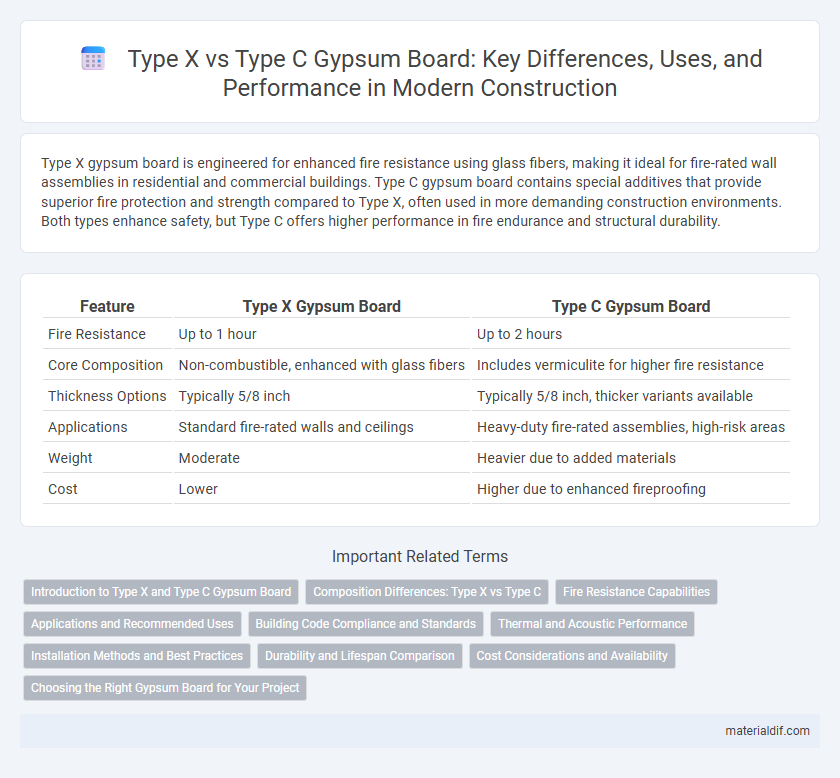

Type X gypsum board is engineered for enhanced fire resistance using glass fibers, making it ideal for fire-rated wall assemblies in residential and commercial buildings. Type C gypsum board contains special additives that provide superior fire protection and strength compared to Type X, often used in more demanding construction environments. Both types enhance safety, but Type C offers higher performance in fire endurance and structural durability.

Table of Comparison

| Feature | Type X Gypsum Board | Type C Gypsum Board |

|---|---|---|

| Fire Resistance | Up to 1 hour | Up to 2 hours |

| Core Composition | Non-combustible, enhanced with glass fibers | Includes vermiculite for higher fire resistance |

| Thickness Options | Typically 5/8 inch | Typically 5/8 inch, thicker variants available |

| Applications | Standard fire-rated walls and ceilings | Heavy-duty fire-rated assemblies, high-risk areas |

| Weight | Moderate | Heavier due to added materials |

| Cost | Lower | Higher due to enhanced fireproofing |

Introduction to Type X and Type C Gypsum Board

Type X gypsum board features enhanced fire-resistant properties achieved through glass fibers reinforcing the gypsum core, making it ideal for fire-rated assemblies. Type C gypsum board offers superior fire resistance compared to Type X, incorporating additives like vermiculite and more glass fibers for extended fire endurance. Both Type X and Type C boards comply with ASTM C1396 standards and are commonly used in commercial construction to meet fire safety codes.

Composition Differences: Type X vs Type C

Type X gypsum board contains glass fibers and special additives to enhance fire resistance, typically with a core formulated for improved structural integrity under heat. Type C gypsum board incorporates a higher concentration of fiberglass and uses a vermiculite additive, providing superior fire resistance and longer fire endurance than Type X. The composition differences result in Type C offering enhanced performance in fire-rated assemblies, while Type X is suitable for standard fire protection needs.

Fire Resistance Capabilities

Type X gypsum board offers fire resistance of up to one hour due to its non-combustible glass fibers and enhanced core design, making it suitable for walls and ceilings requiring moderate fire protection. Type C gypsum board provides superior fire resistance, often rated for up to two hours, thanks to thicker core layers and additives like vermiculite that improve thermal insulation and structural integrity under extreme heat. These enhanced fire resistance capabilities make Type C gypsum board ideal for high-risk areas and stringent building code applications.

Applications and Recommended Uses

Type X gypsum board is primarily used in fire-resistant wall and ceiling assemblies, providing up to one-hour fire protection in residential and commercial buildings. Type C gypsum board features enhanced fire resistance with additives like fiberglass mesh, making it ideal for areas requiring longer fire ratings, such as stairwells and corridors in high-rise structures. Both boards are recommended for use in fire-rated partitions but differ in thickness and fire endurance capabilities tailored to specific building code requirements.

Building Code Compliance and Standards

Type X gypsum board meets ASTM C1396 standards and provides fire resistance of up to one hour, making it compliant with most building codes for fire-rated assemblies. Type C gypsum board, adhering to enhanced ASTM and UL standards, offers superior fire protection with resistance up to two hours, often required in commercial and high-occupancy structures. Both types must be installed according to local building codes such as the International Building Code (IBC) to ensure proper fire barrier performance and certification.

Thermal and Acoustic Performance

Type X gypsum board features enhanced fire resistance with a denser core that also offers improved sound attenuation compared to standard gypsum boards. Type C gypsum board surpasses Type X by incorporating chemical additives that increase thermal performance, providing superior heat resistance and longer fire endurance. Acoustic insulation in Type C boards is marginally better due to thicker core composition and enhanced density, resulting in more effective noise reduction in building applications.

Installation Methods and Best Practices

Type X gypsum board requires staggered joints and minimum 5/8-inch thickness for fire resistance, installed using corrosion-resistant screws spaced 8 inches apart on ceilings and 12 inches on walls. Type C gypsum board, offering enhanced fire and thermal performance, demands careful sealing of joints with fire-resistant tape and compound, along with fastening per manufacturer guidelines to maintain integrity under extreme conditions. Both types benefit from proper framing alignment, moisture control, and adherence to local building codes to ensure optimal safety and durability.

Durability and Lifespan Comparison

Type X gypsum board offers enhanced fire resistance with a core containing glass fibers, providing a standard durability suitable for most commercial applications. Type C gypsum board incorporates special additives like fiberglass and vermiculite, resulting in superior fire resistance and longer lifespan under high-heat conditions. The increased density and specialized composition of Type C contribute to greater durability, making it ideal for environments requiring extended fire protection and structural integrity.

Cost Considerations and Availability

Type X gypsum board generally has a moderate cost and is widely available due to its standard use in fire-resistant construction. Type C gypsum board is typically more expensive because of its enhanced fire-resistance properties and additional additives like glass fibers, making it less commonly stocked. Budget constraints often dictate the choice, with Type X providing cost-effective fire protection, while Type C is preferred in projects requiring superior fire ratings despite higher expenses and limited availability.

Choosing the Right Gypsum Board for Your Project

Type X gypsum board is designed for fire resistance, featuring glass fibers and additives that enhance its ability to withstand fire for up to one hour, making it ideal for residential and commercial projects requiring standard fire-rated assemblies. Type C gypsum board offers superior fire protection with increased thickness and specialized core additives, providing up to two-hour fire resistance, suitable for high-risk areas such as stairwells and corridors in commercial buildings. Selecting the right gypsum board depends on the specific fire safety requirements, building codes, and environmental conditions of the project, ensuring compliance and optimal protection.

Type X gypsum board vs Type C gypsum board Infographic

materialdif.com

materialdif.com