Gypsum core offers excellent fire resistance and sound insulation, making it a popular choice for interior wallboard applications. Fiber reinforced gypsum enhances durability and impact resistance by incorporating fibers, which increase its strength and reduce susceptibility to cracking. This combination results in a more robust material suitable for heavy-use environments while maintaining the core benefits of traditional gypsum.

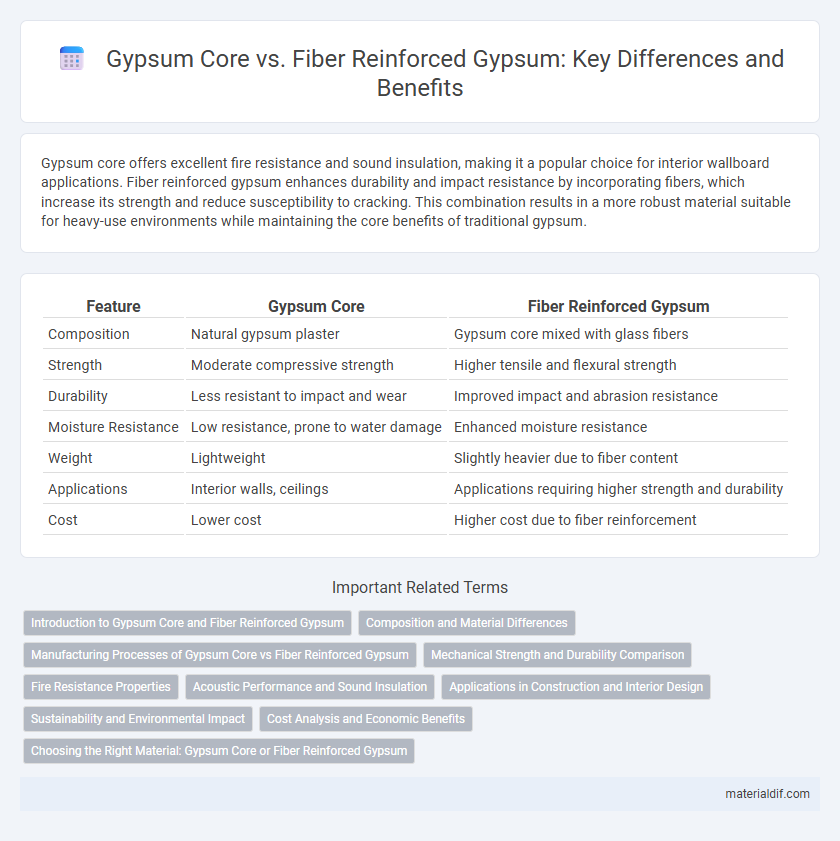

Table of Comparison

| Feature | Gypsum Core | Fiber Reinforced Gypsum |

|---|---|---|

| Composition | Natural gypsum plaster | Gypsum core mixed with glass fibers |

| Strength | Moderate compressive strength | Higher tensile and flexural strength |

| Durability | Less resistant to impact and wear | Improved impact and abrasion resistance |

| Moisture Resistance | Low resistance, prone to water damage | Enhanced moisture resistance |

| Weight | Lightweight | Slightly heavier due to fiber content |

| Applications | Interior walls, ceilings | Applications requiring higher strength and durability |

| Cost | Lower cost | Higher cost due to fiber reinforcement |

Introduction to Gypsum Core and Fiber Reinforced Gypsum

Gypsum core is a widely used building material known for its fire resistance, sound insulation, and moisture regulation properties, primarily consisting of a calcium sulfate dihydrate core. Fiber reinforced gypsum enhances these characteristics by incorporating cellulose or glass fibers, improving tensile strength, durability, and impact resistance. This reinforcement makes fiber reinforced gypsum ideal for applications requiring greater structural integrity and long-term performance in wallboard and ceiling systems.

Composition and Material Differences

Gypsum core consists primarily of calcium sulfate dihydrate, providing a lightweight and cost-effective base ideal for standard drywall applications. Fiber reinforced gypsum incorporates cellulose or glass fibers, enhancing tensile strength, impact resistance, and overall durability. This composite material composition improves structural integrity and makes fiber reinforced gypsum suitable for use in high-performance construction and specialized architectural panels.

Manufacturing Processes of Gypsum Core vs Fiber Reinforced Gypsum

Gypsum core is typically manufactured by mixing calcined gypsum with water and additives, then poured into molds or onto paper facings before drying and curing to achieve a smooth, dense structure. Fiber reinforced gypsum incorporates cellulose or synthetic fibers into this gypsum slurry, enhancing tensile strength and crack resistance through fiber distribution during the forming process. The key difference in manufacturing lies in the fiber integration step, which requires additional mixing and controlled dispersion to maintain homogeneity and optimal mechanical properties.

Mechanical Strength and Durability Comparison

Gypsum core boards offer moderate mechanical strength and are widely used for interior partitions but show limited resistance to impact and moisture. Fiber reinforced gypsum incorporates fiberglass strands, significantly enhancing tensile and flexural strength while improving durability against cracks and environmental factors. The fiber reinforcement results in superior load-bearing capacity and extended lifespan, making it suitable for applications requiring higher structural performance and moisture resistance.

Fire Resistance Properties

Gypsum core panels offer excellent fire resistance due to the presence of chemically bound water, which releases steam to slow heat damage. Fiber reinforced gypsum enhances this property by integrating glass or cellulose fibers, improving structural integrity and reducing cracking under high temperatures. This combination results in superior fire resistance performance, making fiber reinforced gypsum ideal for demanding fire-rated construction applications.

Acoustic Performance and Sound Insulation

Gypsum core panels offer moderate sound insulation with density values typically around 900-1,100 kg/m3, effectively reducing airborne noise in standard interior applications. Fiber reinforced gypsum enhances acoustic performance by incorporating glass fibers, increasing tensile strength and density up to 1,300 kg/m3, which significantly improves sound absorption coefficients and impact resistance. This reinforcement results in better sound insulation ratings (STC up to 55), making fiber reinforced gypsum ideal for environments requiring superior acoustic control.

Applications in Construction and Interior Design

Gypsum core boards are widely used in interior wall partitions and ceilings due to their fire resistance, sound insulation, and smooth finish, making them ideal for residential and commercial construction. Fiber reinforced gypsum (FRG) offers enhanced mechanical strength and durability, making it suitable for exterior facades, curved surfaces, and architectural moldings where higher impact resistance and moisture tolerance are required. Both materials support sustainable building practices but FRG extends application possibilities in demanding environments while maintaining the aesthetic benefits of traditional gypsum.

Sustainability and Environmental Impact

Gypsum core products are highly recyclable and made from abundant natural minerals, minimizing raw material extraction and reducing landfill waste. Fiber reinforced gypsum incorporates cellulose fibers, enhancing durability and reducing resource consumption by extending product lifespan and lowering replacement frequency. Both materials offer sustainable building solutions, but fiber reinforced gypsum provides superior environmental benefits through improved strength and reduced material waste.

Cost Analysis and Economic Benefits

Gypsum core panels offer a lower initial cost compared to fiber reinforced gypsum due to simpler materials and manufacturing processes, making them ideal for budget-sensitive projects. Fiber reinforced gypsum provides enhanced durability and impact resistance, reducing long-term maintenance and replacement expenses, which can translate into greater economic benefits over the lifespan of the installation. Choosing fiber reinforced gypsum often results in a lower total cost of ownership despite higher upfront prices, due to its superior performance in demanding environments.

Choosing the Right Material: Gypsum Core or Fiber Reinforced Gypsum

Gypsum core offers excellent fire resistance and sound insulation, making it ideal for standard drywall applications where cost-efficiency is crucial. Fiber reinforced gypsum enhances tensile strength and impact resistance through cellulose or fiberglass additives, suitable for areas requiring greater durability and moisture resistance. Selecting between these materials depends on the specific structural demands, environmental conditions, and budget constraints of the project.

Gypsum core vs Fiber reinforced gypsum Infographic

materialdif.com

materialdif.com