Casting gypsum is a finely ground, high-purity material designed primarily for detailed mold-making and artistic applications, offering smooth finishes and rapid setting times. Construction gypsum, commonly found as drywall or plasterboard, emphasizes structural strength, fire resistance, and ease of installation for building interiors. Both types share calcium sulfate dihydrate composition but diverge in particle size, additives, and performance characteristics tailored to their specific uses.

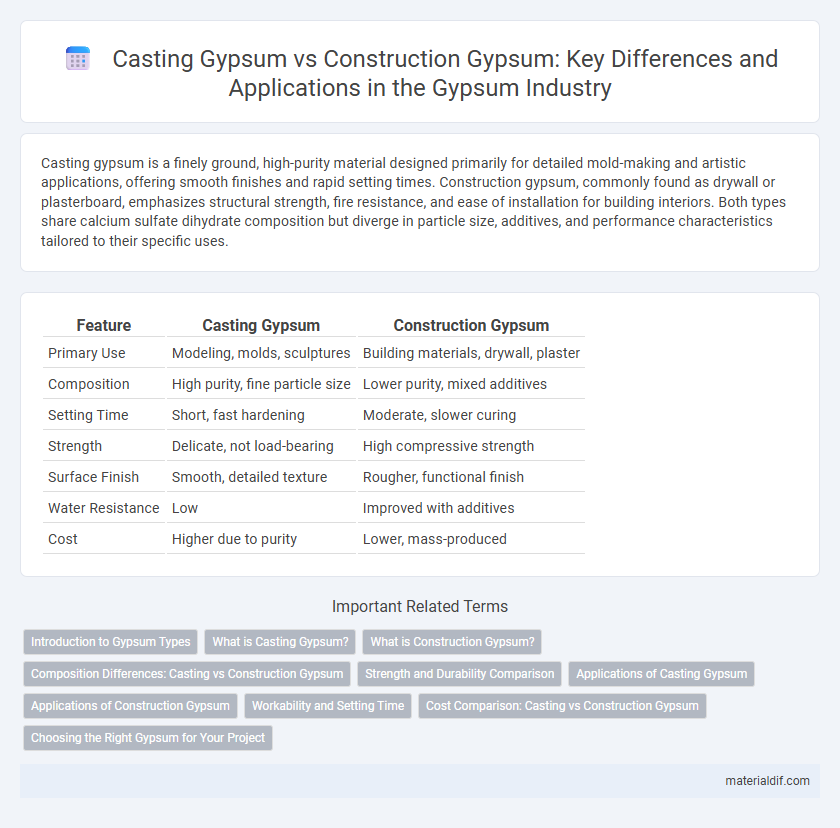

Table of Comparison

| Feature | Casting Gypsum | Construction Gypsum |

|---|---|---|

| Primary Use | Modeling, molds, sculptures | Building materials, drywall, plaster |

| Composition | High purity, fine particle size | Lower purity, mixed additives |

| Setting Time | Short, fast hardening | Moderate, slower curing |

| Strength | Delicate, not load-bearing | High compressive strength |

| Surface Finish | Smooth, detailed texture | Rougher, functional finish |

| Water Resistance | Low | Improved with additives |

| Cost | Higher due to purity | Lower, mass-produced |

Introduction to Gypsum Types

Casting gypsum and construction gypsum differ primarily in purity and setting time; casting gypsum is finely ground with rapid setting properties ideal for detailed molds and sculptures, whereas construction gypsum contains coarser particles and additives for durability and slower curing suited for building applications. The chemical composition remains calcium sulfate dihydrate, but manufacturing processes and particle size distribution tailor each type to its specific use. Understanding these distinctions allows optimal selection for artistic versus structural needs in various industries.

What is Casting Gypsum?

Casting gypsum is a fine, white powder primarily used for making detailed molds, sculptures, and decorative architectural elements due to its smooth texture and quick setting properties. Unlike construction gypsum, which is coarser and formulated for structural applications like drywall and plaster, casting gypsum offers higher purity and strength for precision casting. Its excellent fluidity when mixed with water allows for capturing intricate details in molds, making it ideal for artistic and ornamental purposes.

What is Construction Gypsum?

Construction gypsum is a type of gypsum specifically processed and formulated for use in building materials such as drywall, plaster, and ceiling tiles. It contains additives that enhance its strength, durability, and fire resistance compared to casting gypsum, which is primarily used for mold making and sculpting due to its fine texture and fast setting properties. The chemical composition of construction gypsum is optimized to meet industry standards for structural applications and moisture resistance in construction environments.

Composition Differences: Casting vs Construction Gypsum

Casting gypsum typically consists of finely ground, high-purity calcium sulfate hemihydrate, ensuring a smooth texture and rapid setting time for detailed mold replication. Construction gypsum contains more impurities and additives like retarders or fibers, enhancing its strength and durability for structural applications. The compositional differences directly influence the performance characteristics and end-use suitability of each gypsum type.

Strength and Durability Comparison

Casting gypsum typically exhibits higher compressive strength and finer particle structure, making it ideal for detailed molds and sculptures. Construction gypsum, engineered for wallboard and drywall applications, offers moderate strength optimized for impact resistance and long-term durability in building environments. The difference in additive composition and curing process significantly influences their respective toughness and wear resistance properties.

Applications of Casting Gypsum

Casting gypsum is primarily used in detailed mold-making, sculpture, and architectural ornamentation due to its fine grain and smooth finish, enabling precise replication of intricate designs. It sets quickly and provides high strength and surface hardness, making it ideal for producing decorative elements and prototypes. Unlike construction gypsum, which is formulated for durability and thermal insulation in building walls, casting gypsum excels in artistic and manufacturing applications requiring accuracy and surface detail.

Applications of Construction Gypsum

Construction gypsum primarily serves as a key material in building applications, including drywall panels, plasterboard, and cement additives that enhance fire resistance and sound insulation. Its chemical stability and workability make it ideal for interior wall finishes and ceiling systems, contributing to energy-efficient, lightweight construction. Unlike casting gypsum, construction gypsum is formulated to meet stringent building codes and long-term durability requirements.

Workability and Setting Time

Casting gypsum offers superior workability with a finer particle size that enhances smoothness and detail in molds, making it ideal for artistic and decorative applications. Construction gypsum features a coarser texture to provide increased strength and faster setting times, optimizing it for structural stability in building projects. The setting time for casting gypsum typically ranges from 10 to 20 minutes, while construction gypsum sets more rapidly, often within 5 to 15 minutes, to accommodate faster construction workflows.

Cost Comparison: Casting vs Construction Gypsum

Casting gypsum typically incurs higher material costs due to its fine particle size and purity, which provide superior detail and smooth finishes ideal for molds and sculptures. Construction gypsum, used mainly for drywall and plastering, is more cost-effective with bulk availability and lower processing requirements, making it suitable for large-scale building projects. The price difference reflects the quality demands and application purposes, with casting gypsum priced premium for precision and construction gypsum optimized for affordability.

Choosing the Right Gypsum for Your Project

Casting gypsum offers fine texture and quick setting properties ideal for detailed mold making and artistic applications, whereas construction gypsum provides higher strength and durability suited for wallboard and plastering in building projects. Selecting the right gypsum depends on factors like required finish quality, setting time, and structural demands, with casting gypsum favored for precision and construction gypsum preferred for robust, load-bearing uses. Understanding these distinctions ensures optimal performance and longevity in your project's outcome.

Casting gypsum vs Construction gypsum Infographic

materialdif.com

materialdif.com