Edge-taped gypsum board features a reinforced edge sealed with tape, improving joint durability and reducing the risk of cracks during installation and finishing. Untaped gypsum board lacks this reinforcement, making it more susceptible to edge damage and requiring extra care when finishing seams. Choosing edge-taped gypsum board enhances the overall strength and smoothness of walls and ceilings, especially in high-traffic or high-use areas.

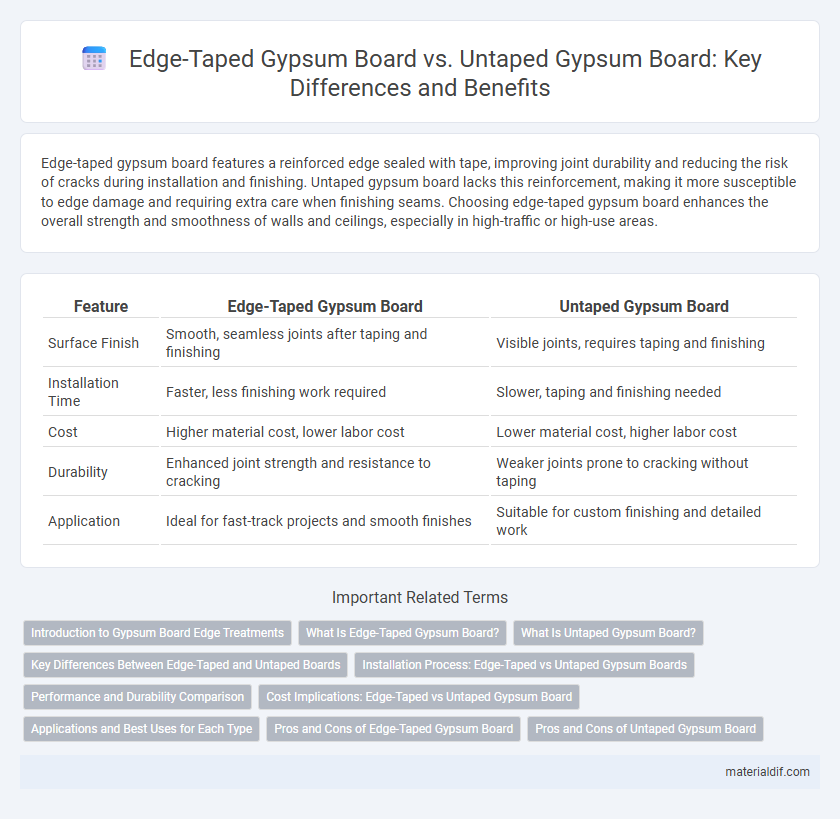

Table of Comparison

| Feature | Edge-Taped Gypsum Board | Untaped Gypsum Board |

|---|---|---|

| Surface Finish | Smooth, seamless joints after taping and finishing | Visible joints, requires taping and finishing |

| Installation Time | Faster, less finishing work required | Slower, taping and finishing needed |

| Cost | Higher material cost, lower labor cost | Lower material cost, higher labor cost |

| Durability | Enhanced joint strength and resistance to cracking | Weaker joints prone to cracking without taping |

| Application | Ideal for fast-track projects and smooth finishes | Suitable for custom finishing and detailed work |

Introduction to Gypsum Board Edge Treatments

Edge-taped gypsum boards feature paper tape applied over the edges to reinforce joints and create a smooth, crack-resistant finish, enhancing durability and paint adhesion. Untaped gypsum boards lack this reinforcement, making edges more prone to damage, cracking, and imperfections during installation and finishing. Proper edge treatment with tape significantly improves the structural integrity and long-term performance of gypsum board assemblies in interior wall and ceiling systems.

What Is Edge-Taped Gypsum Board?

Edge-taped gypsum board features a narrow strip of paper tape applied along the edges to reinforce joints and prevent cracks, enhancing durability and finish quality. This treatment improves the board's resistance to moisture and impact compared to untaped gypsum board, which lacks edge reinforcement and is more prone to damage during handling and installation. Edge-taped gypsum board is commonly used in drywall applications where a smoother, more resilient surface is required for painting or wallpapering.

What Is Untaped Gypsum Board?

Untaped gypsum board refers to drywall sheets that have not been finished with joint tape or compound along the seams, leaving the edges exposed and vulnerable to cracking or moisture infiltration. This untreated state requires additional finishing work for durability and aesthetic appeal in construction projects. Untaped gypsum board is typically used in initial installation phases before the application of tape and joint compound to create a smooth, seamless surface.

Key Differences Between Edge-Taped and Untaped Boards

Edge-taped gypsum boards feature reinforced edges with paper tape that enhances joint strength and reduces cracking during installation, while untaped gypsum boards lack this reinforcement, making them more prone to edge damage. Edge-taped boards streamline finishing processes by providing a smoother surface for joint compounds, resulting in faster and cleaner drywall installation. Untaped gypsum boards require additional taping and finishing, increasing labor time and the risk of visible seams or joint failure.

Installation Process: Edge-Taped vs Untaped Gypsum Boards

Edge-taped gypsum boards feature factory-applied tape and joint compound along the edges, streamlining the installation process by reducing the need for on-site taping and minimizing labor time. Untaped gypsum boards require manual taping and joint finishing during installation, increasing the complexity and duration of the process. The pre-taped edges on edge-taped boards enhance joint durability and facilitate faster wall finishing compared to untaped boards.

Performance and Durability Comparison

Edge-taped gypsum board offers enhanced moisture resistance and improved joint stability compared to untaped gypsum board, reducing the risk of cracking and water damage. The taped edges reinforce the board, providing increased durability in high-traffic or humid environments, while untaped boards are more prone to edge deterioration and require additional finishing work for a smooth surface. Performance-wise, edge-taped gypsum boards ensure a longer-lasting, more resilient wall system ideal for both residential and commercial construction.

Cost Implications: Edge-Taped vs Untaped Gypsum Board

Edge-taped gypsum board typically incurs higher initial costs due to the added manufacturing process of applying edge tape, which enhances moisture resistance and joint strength. Untaped gypsum board is less expensive upfront but may lead to increased labor and material costs during installation and finishing, as additional taping and reinforcement are required. Over time, edge-taped boards can reduce maintenance expenses by minimizing crack formation and improving durability, offering better long-term value despite higher initial investment.

Applications and Best Uses for Each Type

Edge-taped gypsum board features reinforced tape along the edges, providing enhanced durability and resistance to cracking, making it ideal for high-traffic commercial spaces, office buildings, and areas requiring frequent cleaning or repainting. Untaped gypsum board is typically used in residential construction or locations where walls are less susceptible to impacts and where finishing materials, such as plaster or joint compound, provide adequate edge protection. Choosing between edge-taped and untaped gypsum board depends on the project's required finish quality, durability, and environmental conditions.

Pros and Cons of Edge-Taped Gypsum Board

Edge-taped gypsum board offers enhanced moisture resistance and cleaner, more durable edges compared to untaped gypsum board, improving overall surface finish and reducing cracking at joints. However, edge-taped boards tend to be more expensive and may require specialized handling during installation to avoid damaging the tape. Untaped gypsum boards provide greater flexibility for custom edge treatments but often result in increased finishing time and susceptibility to edge damage.

Pros and Cons of Untaped Gypsum Board

Untaped gypsum board offers a smoother surface for custom finishing and painting, allowing greater flexibility in design and texture application. It avoids the risk of tape bubbles or peeling, which can occur with edge-taped gypsum board, but requires more labor and materials to complete joints for a finished look. The absence of tape can result in increased vulnerability to joint cracking if not properly treated, potentially affecting long-term durability.

Edge-Taped Gypsum Board vs Untaped Gypsum Board Infographic

materialdif.com

materialdif.com