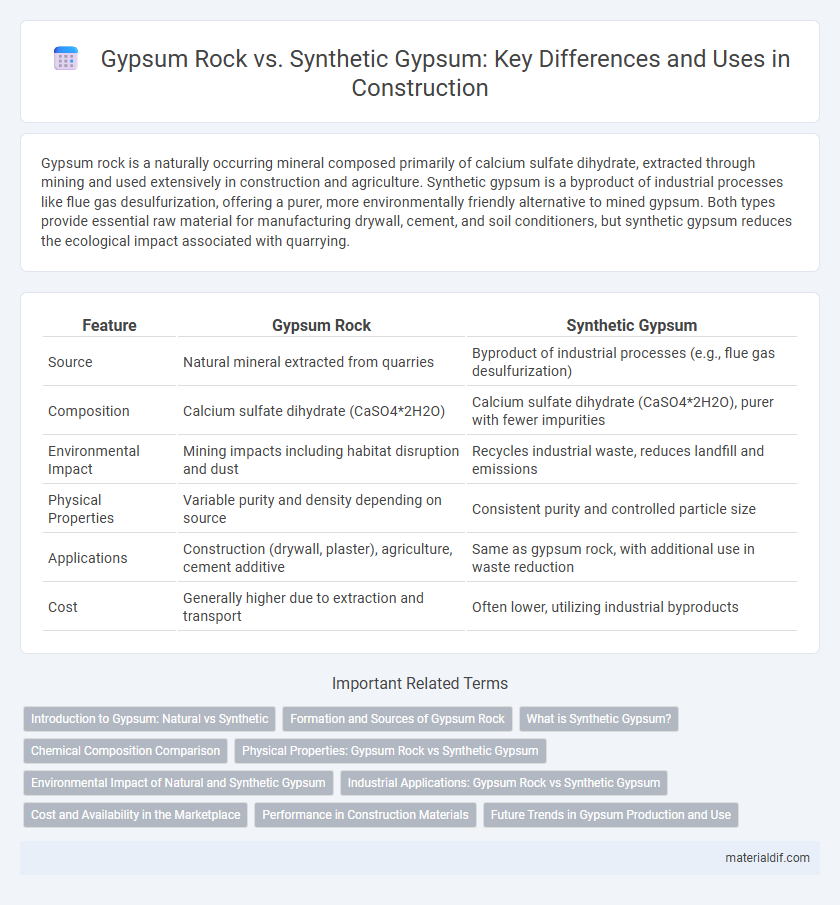

Gypsum rock is a naturally occurring mineral composed primarily of calcium sulfate dihydrate, extracted through mining and used extensively in construction and agriculture. Synthetic gypsum is a byproduct of industrial processes like flue gas desulfurization, offering a purer, more environmentally friendly alternative to mined gypsum. Both types provide essential raw material for manufacturing drywall, cement, and soil conditioners, but synthetic gypsum reduces the ecological impact associated with quarrying.

Table of Comparison

| Feature | Gypsum Rock | Synthetic Gypsum |

|---|---|---|

| Source | Natural mineral extracted from quarries | Byproduct of industrial processes (e.g., flue gas desulfurization) |

| Composition | Calcium sulfate dihydrate (CaSO4*2H2O) | Calcium sulfate dihydrate (CaSO4*2H2O), purer with fewer impurities |

| Environmental Impact | Mining impacts including habitat disruption and dust | Recycles industrial waste, reduces landfill and emissions |

| Physical Properties | Variable purity and density depending on source | Consistent purity and controlled particle size |

| Applications | Construction (drywall, plaster), agriculture, cement additive | Same as gypsum rock, with additional use in waste reduction |

| Cost | Generally higher due to extraction and transport | Often lower, utilizing industrial byproducts |

Introduction to Gypsum: Natural vs Synthetic

Gypsum rock is a natural mineral composed primarily of calcium sulfate dihydrate, formed through the evaporation of saline water in sedimentary environments. Synthetic gypsum, by contrast, is a man-made byproduct generated mainly from industrial processes such as flue gas desulfurization in power plants. Both types of gypsum serve as essential raw materials for producing wallboard, cement, and soil conditioners, with synthetic gypsum offering a sustainable alternative by recycling industrial waste.

Formation and Sources of Gypsum Rock

Gypsum rock forms naturally through the evaporation of saline water in sedimentary basins, primarily sourced from ancient sea beds rich in calcium sulfate minerals. Synthetic gypsum is produced as a byproduct of industrial processes such as flue gas desulfurization in coal-fired power plants, offering a man-made alternative with consistent purity. While gypsum rock extraction depends on geological deposits, synthetic gypsum relies on industrial emissions, providing a sustainable solution by recycling waste materials.

What is Synthetic Gypsum?

Synthetic gypsum is a byproduct produced primarily from flue gas desulfurization (FGD) processes in power plants that burn coal. This man-made gypsum closely resembles natural gypsum rock in composition and purity, often containing high levels of calcium sulfate dihydrate. It serves as a sustainable alternative in industries such as construction, especially for drywall manufacturing, reducing the demand for mining natural gypsum.

Chemical Composition Comparison

Gypsum rock primarily consists of calcium sulfate dihydrate (CaSO4*2H2O), characterized by natural impurities like quartz, clay, and organic matter. Synthetic gypsum, produced from industrial processes such as flue gas desulfurization, typically contains higher purity calcium sulfate dihydrate with minimal contaminants and more consistent chemical composition. The elevated purity of synthetic gypsum enhances its suitability for applications requiring precise chemical properties and reduces variability found in natural gypsum rock.

Physical Properties: Gypsum Rock vs Synthetic Gypsum

Gypsum rock typically exhibits a crystalline structure with natural variations in hardness, density, and moisture content, whereas synthetic gypsum offers more uniform physical properties due to controlled manufacturing processes. The density of gypsum rock ranges from 2.3 to 2.4 g/cm3, while synthetic gypsum usually maintains consistent density around 2.3 g/cm3, leading to predictable performance in construction applications. Synthetic gypsum also tends to have lower impurity levels, resulting in enhanced purity and improved workability compared to natural gypsum rock.

Environmental Impact of Natural and Synthetic Gypsum

Natural gypsum rock extraction involves mining processes that disrupt land and ecosystems, generating dust and consuming significant energy, leading to habitat loss and greenhouse gas emissions. In contrast, synthetic gypsum, a byproduct of industrial processes like flue-gas desulfurization, reduces waste by repurposing pollutants and lowers environmental impact through decreased mining activities and resource conservation. Utilizing synthetic gypsum supports circular economy principles, cuts carbon footprints, and minimizes ecological damage compared to reliance on natural gypsum rock.

Industrial Applications: Gypsum Rock vs Synthetic Gypsum

Gypsum rock is widely utilized in construction for producing cement, plaster, and drywall due to its natural purity and availability. Synthetic gypsum, a byproduct of industrial processes like flue gas desulfurization, offers a consistent chemical composition ideal for high-quality wallboard manufacturing and soil conditioning. Industrial applications favor synthetic gypsum for its environmental benefits and enhanced performance characteristics in construction materials compared to traditional gypsum rock.

Cost and Availability in the Marketplace

Gypsum rock is typically more cost-effective due to its natural abundance and widespread mining operations, whereas synthetic gypsum, produced as a byproduct of industrial processes like flue gas desulfurization, often carries higher processing costs. Availability of gypsum rock is generally more stable and region-specific, depending on geological deposits, while synthetic gypsum availability fluctuates with industrial activity and environmental regulations. Market prices for synthetic gypsum can be less predictable compared to gypsum rock, influenced by factors such as industrial output and disposal regulations.

Performance in Construction Materials

Gypsum rock offers natural hardness and durability, making it ideal for construction materials like drywall and plaster. Synthetic gypsum, produced as a byproduct of industrial processes, often exhibits higher purity and finer particle size, enhancing workability and consistency in applications. Both materials contribute to structural integrity, but synthetic gypsum typically provides improved setting times and surface finish in construction projects.

Future Trends in Gypsum Production and Use

Gypsum rock extraction is expected to decline as synthetic gypsum, a byproduct of industrial processes like flue gas desulfurization, grows due to its environmental benefits and high purity levels. Innovations in sustainable construction materials drive the adoption of synthetic gypsum in drywall and cement production, aligning with carbon reduction goals. Advancements in recycling and resource-efficient technologies will further shift the industry toward synthetic gypsum, enhancing circular economy practices in building material manufacturing.

Gypsum Rock vs Synthetic Gypsum Infographic

materialdif.com

materialdif.com