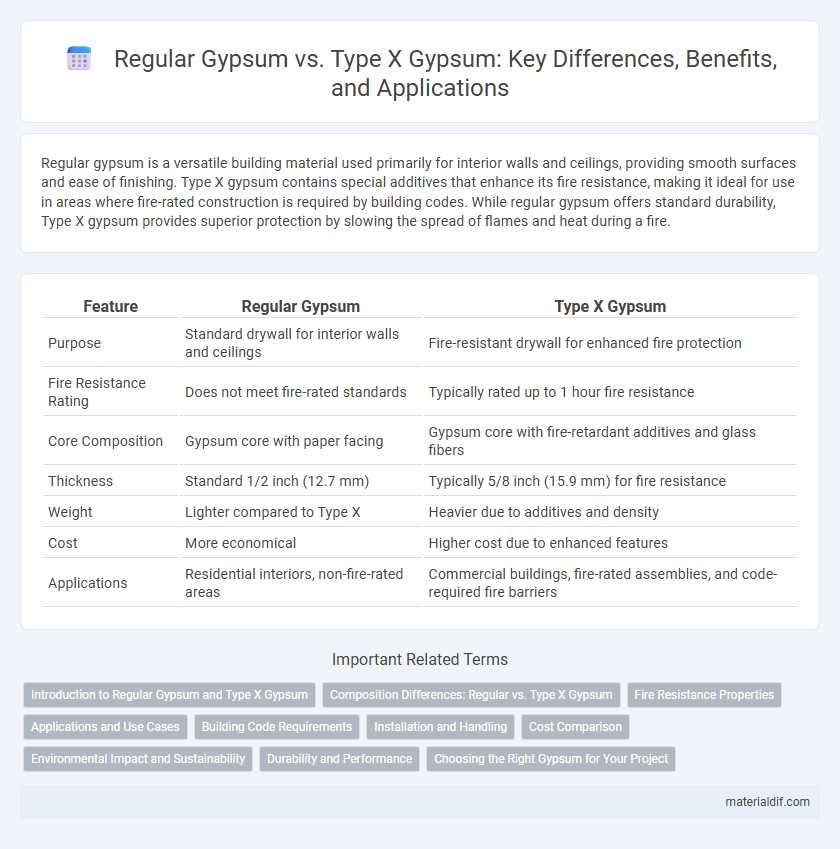

Regular gypsum is a versatile building material used primarily for interior walls and ceilings, providing smooth surfaces and ease of finishing. Type X gypsum contains special additives that enhance its fire resistance, making it ideal for use in areas where fire-rated construction is required by building codes. While regular gypsum offers standard durability, Type X gypsum provides superior protection by slowing the spread of flames and heat during a fire.

Table of Comparison

| Feature | Regular Gypsum | Type X Gypsum |

|---|---|---|

| Purpose | Standard drywall for interior walls and ceilings | Fire-resistant drywall for enhanced fire protection |

| Fire Resistance Rating | Does not meet fire-rated standards | Typically rated up to 1 hour fire resistance |

| Core Composition | Gypsum core with paper facing | Gypsum core with fire-retardant additives and glass fibers |

| Thickness | Standard 1/2 inch (12.7 mm) | Typically 5/8 inch (15.9 mm) for fire resistance |

| Weight | Lighter compared to Type X | Heavier due to additives and density |

| Cost | More economical | Higher cost due to enhanced features |

| Applications | Residential interiors, non-fire-rated areas | Commercial buildings, fire-rated assemblies, and code-required fire barriers |

Introduction to Regular Gypsum and Type X Gypsum

Regular gypsum is a widely used building material known for its ease of installation, affordability, and fire resistance properties suitable for standard interior walls and ceilings. Type X gypsum is specifically engineered with enhanced fire-resistant additives, enabling it to provide extended fire protection and meet stringent building code requirements in fire-rated assemblies. Both materials share gypsum as the base component but differ significantly in their fire resistance performance and application scope.

Composition Differences: Regular vs. Type X Gypsum

Regular gypsum primarily consists of calcium sulfate dihydrate, which provides basic fire resistance and structural support in drywall applications. Type X gypsum incorporates glass fibers within the calcium sulfate matrix, significantly enhancing its fire-resistant properties by increasing the material's ability to withstand high temperatures and slow fire penetration. This compositional difference makes Type X gypsum the preferred choice for fire-rated assemblies in construction.

Fire Resistance Properties

Regular gypsum offers basic fire resistance suitable for residential applications, with a typical fire rating of up to 30 minutes. Type X gypsum contains special non-combustible fibers and additives that enhance its fire-resistant capabilities, providing fire ratings of 1 hour or more. The improved thermal barrier performance of Type X gypsum significantly slows heat transfer, making it essential for commercial building safety codes.

Applications and Use Cases

Regular gypsum is widely used in residential interiors for standard wallboards, ceilings, and partitions due to its cost-effectiveness and ease of installation. Type X gypsum incorporates glass fibers and other additives to provide enhanced fire resistance, making it essential for commercial buildings, fire-rated walls, and areas requiring compliance with strict fire codes. Its use in fire barriers, stairwells, and shared walls helps improve safety by slowing fire spread and meeting insurance and building regulations.

Building Code Requirements

Regular gypsum boards meet general building code requirements for fire resistance in standard residential and commercial constructions, providing basic wall and ceiling protection. Type X gypsum boards are specifically designed to comply with stricter fire-resistance standards outlined in the International Building Code (IBC), featuring enhanced fire-retardant additives that extend fire resistance up to one hour or more. Building codes typically mandate the use of Type X gypsum in fire-rated assemblies such as fire barriers, corridors, and stairwells to ensure occupant safety and structural integrity during fire events.

Installation and Handling

Regular gypsum boards are easier to cut and handle due to their lighter weight and softer core composition, making installation quicker and less labor-intensive. Type X gypsum incorporates glass fibers for enhanced fire resistance, resulting in a denser and heavier panel that requires specialized tools and more careful handling during installation. Contractors often need additional support and fasteners for Type X gypsum to meet fire code requirements and maintain structural integrity.

Cost Comparison

Regular gypsum typically costs less than Type X gypsum due to its standard fire resistance properties and simpler manufacturing process. Type X gypsum sheets, engineered with glass fibers for enhanced fire resistance, incur higher production costs that reflect in their market price, often 25-40% more expensive than regular gypsum. Budget considerations must balance initial costs against the increased safety and code compliance benefits of Type X gypsum in fire-rated construction projects.

Environmental Impact and Sustainability

Regular gypsum offers moderate environmental benefits by utilizing natural mineral deposits and recycling industrial byproducts, yet it lacks fire resistance, which can affect building longevity and sustainability. Type X gypsum contains glass fibers and additives enhancing fire resistance, potentially extending building lifespan and reducing resource consumption over time, though its production involves more energy-intensive processes. Choosing Type X gypsum supports improved safety standards and long-term sustainability goals, balancing environmental impact with enhanced performance in fire-rated construction applications.

Durability and Performance

Regular gypsum offers standard durability suitable for most interior applications, providing basic fire resistance and structural support. Type X gypsum, enhanced with glass fibers and other additives, delivers superior fire resistance and durability, making it ideal for environments requiring higher safety standards. Its improved performance under heat exposure ensures extended structural integrity during fire incidents.

Choosing the Right Gypsum for Your Project

Regular gypsum boards offer standard fire resistance suitable for residential and light commercial applications, providing cost-effective and easy installation options. Type X gypsum boards contain non-combustible fibers enhancing fire-resistance ratings up to 1-2 hours, making them essential for commercial buildings and code-compliant structures requiring stringent fire protection. Selecting between regular and Type X gypsum hinges on project-specific fire safety codes, budget constraints, and the desired level of fire protection to ensure compliance and durability.

Regular gypsum vs Type X gypsum Infographic

materialdif.com

materialdif.com