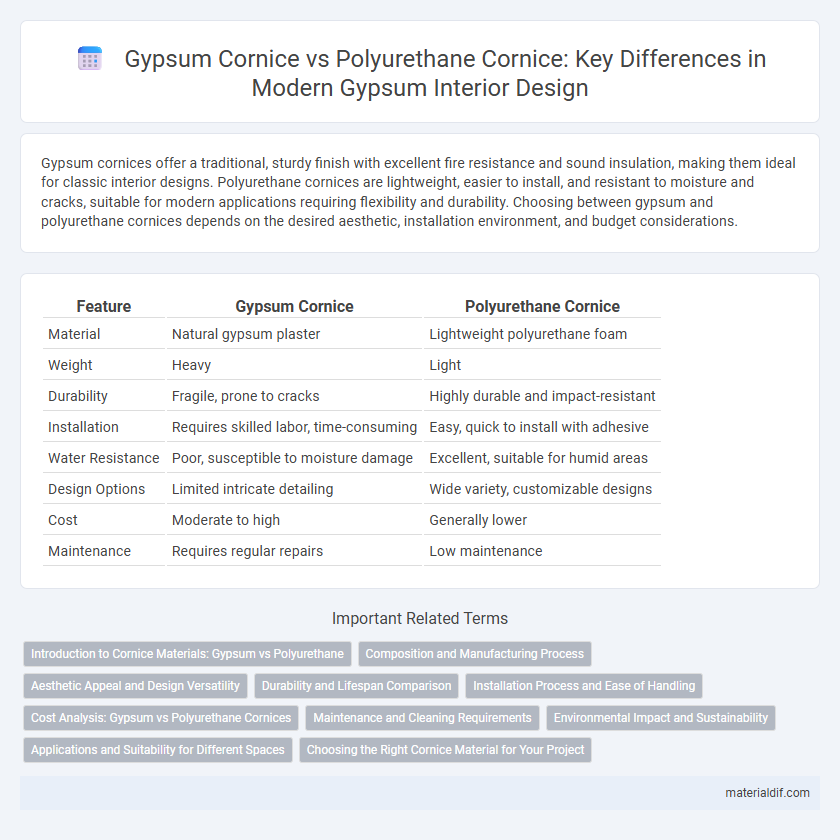

Gypsum cornices offer a traditional, sturdy finish with excellent fire resistance and sound insulation, making them ideal for classic interior designs. Polyurethane cornices are lightweight, easier to install, and resistant to moisture and cracks, suitable for modern applications requiring flexibility and durability. Choosing between gypsum and polyurethane cornices depends on the desired aesthetic, installation environment, and budget considerations.

Table of Comparison

| Feature | Gypsum Cornice | Polyurethane Cornice |

|---|---|---|

| Material | Natural gypsum plaster | Lightweight polyurethane foam |

| Weight | Heavy | Light |

| Durability | Fragile, prone to cracks | Highly durable and impact-resistant |

| Installation | Requires skilled labor, time-consuming | Easy, quick to install with adhesive |

| Water Resistance | Poor, susceptible to moisture damage | Excellent, suitable for humid areas |

| Design Options | Limited intricate detailing | Wide variety, customizable designs |

| Cost | Moderate to high | Generally lower |

| Maintenance | Requires regular repairs | Low maintenance |

Introduction to Cornice Materials: Gypsum vs Polyurethane

Gypsum cornices are made from mineral-based plaster, offering excellent fire resistance and durability ideal for classic interior designs. Polyurethane cornices, composed of lightweight synthetic foam, provide greater flexibility and ease of installation with moisture-resistant properties suitable for modern, intricate moldings. Both materials serve decorative and functional purposes, but gypsum excels in traditional sturdiness while polyurethane offers versatility and water resistance.

Composition and Manufacturing Process

Gypsum cornices are composed primarily of natural gypsum plaster mixed with water and additives, then molded and dried through a setting process that involves chemical hydration. Polyurethane cornices consist of polymer resin combined with fillers and catalysts, created through a chemical reaction in a mold that results in a lightweight, flexible product. The gypsum manufacturing process involves casting and curing, while polyurethane is produced via injection molding or casting with rapid curing times and enhanced durability.

Aesthetic Appeal and Design Versatility

Gypsum cornices offer a classic, elegant finish with intricate detailing that enhances traditional architectural styles, while polyurethane cornices provide superior design versatility due to their lightweight nature and ease of customization for modern or ornate patterns. Polyurethane is resistant to moisture and insects, making it ideal for both interior and exterior applications without compromising aesthetic appeal. The choice impacts not only the visual sophistication but also the durability and maintenance considerations of the cornice design.

Durability and Lifespan Comparison

Gypsum cornices provide excellent fire resistance and a hard, durable finish ideal for traditional interiors but are prone to cracking and water damage over time. Polyurethane cornices offer superior flexibility, resisting cracks, moisture, and termites, which extends their lifespan significantly in varying environmental conditions. The lifespan of polyurethane cornices typically exceeds 30 years, whereas gypsum cornices may require repairs or replacement within 10 to 15 years under similar conditions.

Installation Process and Ease of Handling

Gypsum cornices require careful handling due to their brittleness and heavier weight, often necessitating skilled labor and multiple installation steps including wetting and curing time. Polyurethane cornices are lightweight, flexible, and easier to cut and shape, allowing for faster, less labor-intensive installation with minimal tools. The ease of handling polyurethane reduces the risk of damage during installation, making it a preferred choice for complex or decorative designs.

Cost Analysis: Gypsum vs Polyurethane Cornices

Gypsum cornices typically have a lower initial cost compared to polyurethane cornices but may incur higher installation expenses due to their weight and fragility. Polyurethane cornices, while more expensive upfront, offer savings in labor costs thanks to their lightweight nature and ease of handling. Over time, polyurethane's durability and resistance to moisture reduce maintenance costs, potentially making it more cost-effective than gypsum for long-term applications.

Maintenance and Cleaning Requirements

Gypsum cornices require careful maintenance as they are prone to cracking and water damage, necessitating gentle cleaning with a soft, dry cloth to preserve their integrity. Polyurethane cornices offer superior durability and resistance to moisture, allowing for easier cleaning with mild soapy water without the risk of damage. Regular dusting and occasional wiping keep both types in good condition, but polyurethane's low porosity and resilience significantly reduce long-term upkeep.

Environmental Impact and Sustainability

Gypsum cornices are made from natural calcium sulfate, which is biodegradable and has a lower environmental footprint due to its abundant availability and energy-efficient manufacturing process. Polyurethane cornices, derived from petroleum-based products, contribute to higher carbon emissions and pose challenges in recycling and biodegradability, impacting their sustainability negatively. Choosing gypsum cornices supports eco-friendly building practices by reducing waste and promoting the use of renewable, non-toxic materials.

Applications and Suitability for Different Spaces

Gypsum cornices excel in traditional and formal interior spaces due to their fire resistance and ability to hold intricate, classical detailing, making them ideal for residential and heritage buildings. Polyurethane cornices offer superior moisture resistance and lightweight properties, making them suitable for modern commercial spaces, bathrooms, and humid environments where durability and ease of installation are critical. Both materials adapt to various architectural styles, but selecting gypsum or polyurethane depends on the space's moisture levels, structural requirements, and design complexity.

Choosing the Right Cornice Material for Your Project

Gypsum cornices offer excellent fire resistance and a smooth finish ideal for traditional interiors, while polyurethane cornices provide superior flexibility, lightweight installation, and resistance to moisture, making them suitable for complex designs and humid environments. Choosing the right cornice material depends on project requirements such as durability, environmental conditions, and budget constraints. For restoration or high-end finishes, gypsum is preferable, whereas polyurethane suits modern builds requiring quick installation and intricate detailing.

Gypsum cornice vs Polyurethane cornice Infographic

materialdif.com

materialdif.com