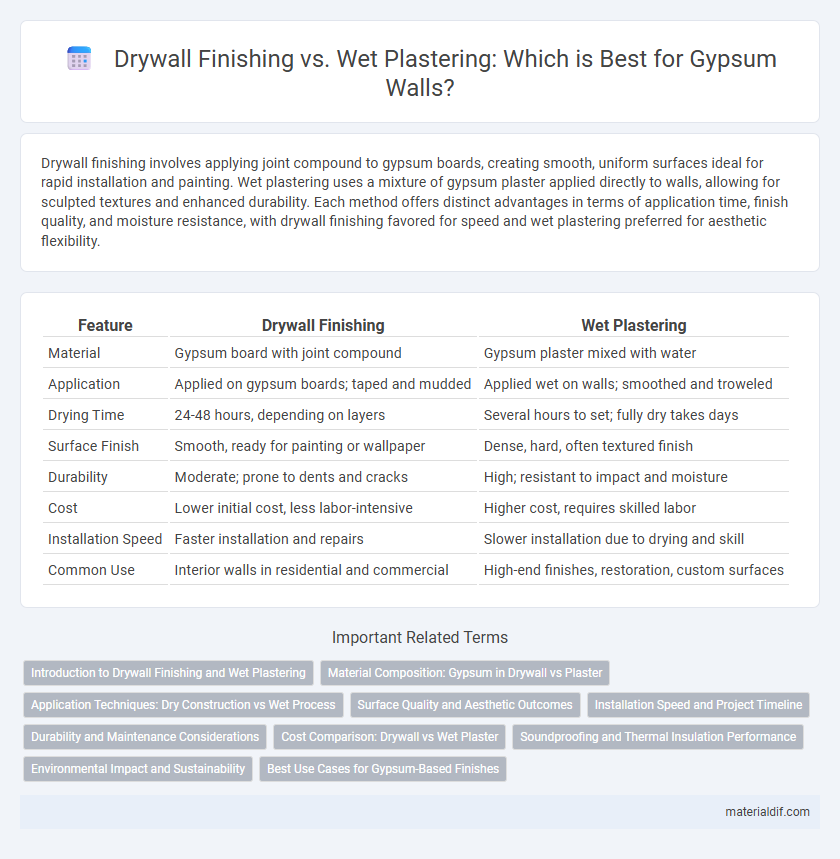

Drywall finishing involves applying joint compound to gypsum boards, creating smooth, uniform surfaces ideal for rapid installation and painting. Wet plastering uses a mixture of gypsum plaster applied directly to walls, allowing for sculpted textures and enhanced durability. Each method offers distinct advantages in terms of application time, finish quality, and moisture resistance, with drywall finishing favored for speed and wet plastering preferred for aesthetic flexibility.

Table of Comparison

| Feature | Drywall Finishing | Wet Plastering |

|---|---|---|

| Material | Gypsum board with joint compound | Gypsum plaster mixed with water |

| Application | Applied on gypsum boards; taped and mudded | Applied wet on walls; smoothed and troweled |

| Drying Time | 24-48 hours, depending on layers | Several hours to set; fully dry takes days |

| Surface Finish | Smooth, ready for painting or wallpaper | Dense, hard, often textured finish |

| Durability | Moderate; prone to dents and cracks | High; resistant to impact and moisture |

| Cost | Lower initial cost, less labor-intensive | Higher cost, requires skilled labor |

| Installation Speed | Faster installation and repairs | Slower installation due to drying and skill |

| Common Use | Interior walls in residential and commercial | High-end finishes, restoration, custom surfaces |

Introduction to Drywall Finishing and Wet Plastering

Drywall finishing involves applying joint compound over gypsum board seams to create a smooth, seamless surface, ideal for quick installation and easy repairs. Wet plastering uses a mixture of gypsum or lime plaster applied wet onto walls, offering a more durable and traditional finish with excellent sound insulation. Both methods enhance wall aesthetics and durability but differ in application techniques and drying times.

Material Composition: Gypsum in Drywall vs Plaster

Drywall finishing uses gypsum boards composed of a core of gypsum sandwiched between paper facings, providing a uniform and lightweight material ideal for rapid installation. Wet plastering relies on a mixture of gypsum plaster, water, sand, and sometimes lime, creating a thick, hardening layer that bonds directly to surfaces for enhanced texture and durability. The gypsum in drywall is pre-formed and processed for consistency, while plaster gypsum is raw and mixed on-site, impacting setting time and finish quality.

Application Techniques: Dry Construction vs Wet Process

Drywall finishing utilizes gypsum boards applied in dry construction, enabling faster installation with minimal curing time, while wet plastering involves applying a gypsum-based wet mix that requires skilled troweling and extended drying periods. Dry construction techniques allow for precise joint taping and sanding to create smooth surfaces, optimizing efficiency in commercial and residential projects. In contrast, the wet process delivers superior surface durability and mold resistance, favored in high-humidity environments but demands more labor-intensive application and controlled curing conditions.

Surface Quality and Aesthetic Outcomes

Drywall finishing offers a smooth, uniform surface ideal for modern interiors with consistent paint adhesion and minimal texture. Wet plastering produces a highly durable, seamless finish that can be sculpted for intricate textures and enhances acoustic insulation. Both methods impact surface quality and aesthetic outcomes, with drywall providing speed and cost-efficiency, while wet plastering delivers superior longevity and refined architectural detail.

Installation Speed and Project Timeline

Drywall finishing significantly accelerates the installation process with faster taping, mudding, and sanding stages, often completing within 1-3 days compared to wet plastering's 5-7 days drying time. Wet plastering requires multiple coats with extended curing periods, extending the project timeline but offering enhanced durability and a smoother finish. Choosing drywall finishing benefits tight schedules, while wet plastering suits projects prioritizing longevity and surface quality.

Durability and Maintenance Considerations

Drywall finishing offers ease of maintenance with its smooth, paint-ready surface that resists cracking and requires minimal upkeep, making it durable for most residential applications. Wet plastering, while more labor-intensive, provides a harder, more impact-resistant finish that can better withstand moisture and long-term wear in high-traffic or humid environments. Choosing between the two depends on balancing initial installation effort with the desired longevity and specific maintenance needs of the gypsum surface.

Cost Comparison: Drywall vs Wet Plaster

Drywall finishing generally costs less than wet plastering due to lower material expenses and faster installation times, averaging between $1.50 to $3 per square foot compared to wet plaster's $3 to $7 per square foot. Labor costs for wet plaster increase because of its complexity and longer drying times, resulting in higher overall project budgets. Choosing drywall finishing can significantly reduce upfront costs while still providing a smooth, paint-ready surface.

Soundproofing and Thermal Insulation Performance

Drywall finishing with gypsum boards offers moderate soundproofing and thermal insulation, benefiting from multiple layers and specialized insulating materials like fiberglass behind the panels. Wet plastering provides superior soundproofing by creating a dense, seamless surface that reduces sound transmission and improves thermal mass, enhancing heat retention and energy efficiency. Both methods can be optimized for insulation, but wet plaster inherently delivers higher performance due to its thickness and material density.

Environmental Impact and Sustainability

Drywall finishing produces less material waste and typically uses gypsum boards that are recyclable, contributing to reduced landfill impact and lower resource consumption. Wet plastering, though durable and providing better thermal insulation, often involves chemical additives and water-intensive processes that increase environmental footprints. Choosing drywall finishing supports sustainability efforts by minimizing water use and promoting efficient material recycling in construction projects.

Best Use Cases for Gypsum-Based Finishes

Drywall finishing using gypsum boards is ideal for fast, cost-effective interior wall construction in residential and commercial buildings, providing smooth surfaces ready for painting or wallpapering. Wet plastering with gypsum offers superior durability and moisture resistance, making it best suited for high-humidity areas such as kitchens and bathrooms. Both methods leverage gypsum's fire-resistant and mold-inhibiting properties, enhancing indoor air quality and structural safety.

Drywall Finishing vs Wet Plastering Infographic

materialdif.com

materialdif.com