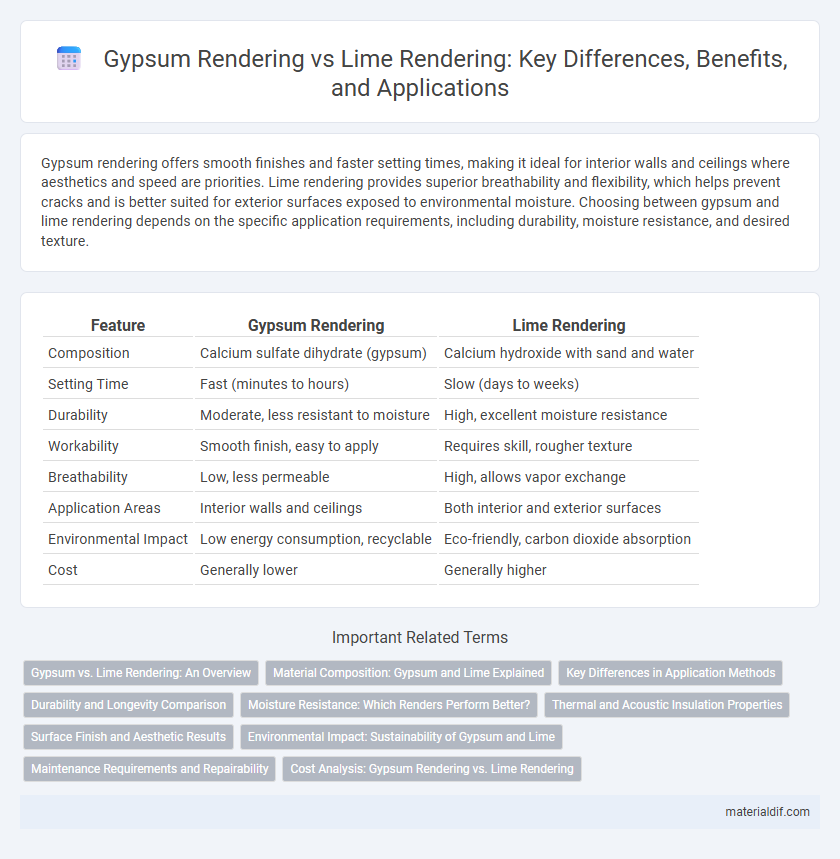

Gypsum rendering offers smooth finishes and faster setting times, making it ideal for interior walls and ceilings where aesthetics and speed are priorities. Lime rendering provides superior breathability and flexibility, which helps prevent cracks and is better suited for exterior surfaces exposed to environmental moisture. Choosing between gypsum and lime rendering depends on the specific application requirements, including durability, moisture resistance, and desired texture.

Table of Comparison

| Feature | Gypsum Rendering | Lime Rendering |

|---|---|---|

| Composition | Calcium sulfate dihydrate (gypsum) | Calcium hydroxide with sand and water |

| Setting Time | Fast (minutes to hours) | Slow (days to weeks) |

| Durability | Moderate, less resistant to moisture | High, excellent moisture resistance |

| Workability | Smooth finish, easy to apply | Requires skill, rougher texture |

| Breathability | Low, less permeable | High, allows vapor exchange |

| Application Areas | Interior walls and ceilings | Both interior and exterior surfaces |

| Environmental Impact | Low energy consumption, recyclable | Eco-friendly, carbon dioxide absorption |

| Cost | Generally lower | Generally higher |

Gypsum vs. Lime Rendering: An Overview

Gypsum rendering offers a smooth, fine finish ideal for interior walls, while lime rendering provides superior breathability and durability, making it suitable for external surfaces. Gypsum sets quickly, reducing construction time, but lacks the moisture resistance and flexibility of lime rendering. Lime's natural antifungal properties and ability to accommodate structural movement enhance building longevity compared to the more brittle gypsum render.

Material Composition: Gypsum and Lime Explained

Gypsum rendering consists primarily of calcium sulfate dihydrate, providing rapid setting and smooth finishes ideal for interior walls, while lime rendering is based on calcium hydroxide derived from limestone, offering superior breathability and flexibility suited for exterior applications. Gypsum's chemical composition enables faster drying and less cracking, whereas lime's carbonation process enhances durability and moisture regulation. Understanding these material differences is crucial for selecting the appropriate rendering system based on environmental conditions and substrate requirements.

Key Differences in Application Methods

Gypsum rendering involves applying a smooth, fast-setting plaster that requires a dry surface and is typically used for interior walls, whereas lime rendering uses a slower-drying, breathable material suitable for both interior and exterior surfaces. Gypsum plaster sets through chemical hydration, enabling quicker finishing, while lime sets by carbonation, allowing flexibility and moisture regulation. The application of gypsum requires precise mixing and swift application to prevent cracking, contrasting with lime's tolerance for moisture and its ability to self-heal minor cracks over time.

Durability and Longevity Comparison

Gypsum rendering offers smooth finishes but is less durable compared to lime rendering, as it can degrade faster in moist environments due to its water solubility. Lime rendering provides enhanced durability and longevity by resisting cracking and moisture penetration, making it suitable for external applications exposed to harsh weather. Its natural flexibility and breathability extend the lifespan of walls, outperforming gypsum renders in long-term structural protection.

Moisture Resistance: Which Renders Perform Better?

Gypsum rendering offers moderate moisture resistance but tends to absorb water, leading to potential deterioration in damp environments. Lime rendering excels in moisture resistance due to its breathable nature, allowing walls to release trapped moisture and reducing the risk of mold and damage. For areas prone to high humidity or frequent water exposure, lime renders provide superior durability and long-term performance compared to gypsum renders.

Thermal and Acoustic Insulation Properties

Gypsum rendering offers superior thermal insulation due to its low thermal conductivity, effectively reducing heat transfer in buildings. Lime rendering, while breathable and moisture-regulating, generally provides less acoustic insulation compared to gypsum, which dampens sound transmission more efficiently. Both materials enhance indoor comfort, but gypsum excels in soundproofing and thermal retention, making it a preferred choice for energy-efficient and noise-sensitive structures.

Surface Finish and Aesthetic Results

Gypsum rendering provides a smooth, fine surface finish that enhances indoor aesthetics with its uniform texture and bright white appearance, ideal for modern interiors. Lime rendering offers a more textured surface with a natural, matte finish that develops a charming patina over time, suitable for traditional or rustic designs. Gypsum is less breathable and moisture-resistant compared to lime, which allows lime renders to maintain durability and aesthetic appeal in humid environments.

Environmental Impact: Sustainability of Gypsum and Lime

Gypsum rendering offers a lower environmental impact due to its abundant natural availability and energy-efficient manufacturing process, producing significantly less carbon dioxide compared to lime rendering. Lime rendering, while also sustainable with its carbon-absorbing curing process, requires higher energy input for limestone calcination, resulting in larger CO2 emissions. Both materials contribute to sustainable construction, but gypsum's reduced carbon footprint and recyclability position it as a more eco-friendly option in modern building practices.

Maintenance Requirements and Repairability

Gypsum rendering requires careful protection from moisture due to its lower water resistance compared to lime rendering, increasing maintenance frequency in damp environments. Lime rendering's natural breathability and flexibility reduce the likelihood of cracking, making repairs less frequent and more straightforward. For long-term durability, lime rendering often offers enhanced maintenance efficiency and easier spot repairs compared to gypsum-based finishes.

Cost Analysis: Gypsum Rendering vs. Lime Rendering

Gypsum rendering generally offers a lower initial cost compared to lime rendering due to faster application times and reduced labor expenses. Lime rendering, while often more expensive upfront, provides greater durability and breathability, potentially reducing long-term maintenance costs. Evaluating total lifecycle expenses highlights gypsum as cost-effective for quick projects, whereas lime is advantageous for sustainable, moisture-regulating finishes.

Gypsum rendering vs Lime rendering Infographic

materialdif.com

materialdif.com