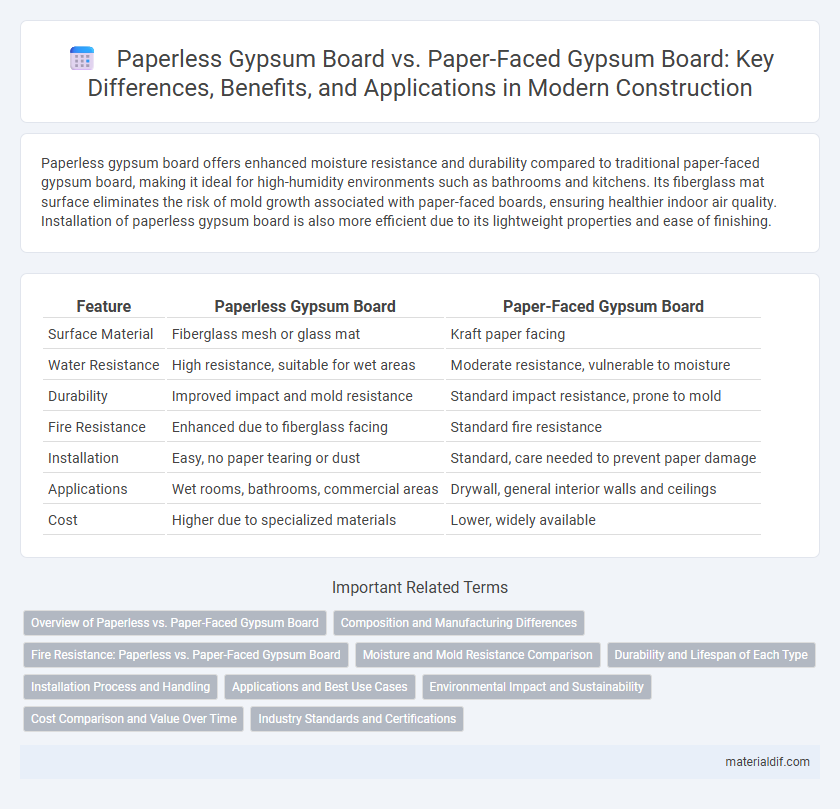

Paperless gypsum board offers enhanced moisture resistance and durability compared to traditional paper-faced gypsum board, making it ideal for high-humidity environments such as bathrooms and kitchens. Its fiberglass mat surface eliminates the risk of mold growth associated with paper-faced boards, ensuring healthier indoor air quality. Installation of paperless gypsum board is also more efficient due to its lightweight properties and ease of finishing.

Table of Comparison

| Feature | Paperless Gypsum Board | Paper-Faced Gypsum Board |

|---|---|---|

| Surface Material | Fiberglass mesh or glass mat | Kraft paper facing |

| Water Resistance | High resistance, suitable for wet areas | Moderate resistance, vulnerable to moisture |

| Durability | Improved impact and mold resistance | Standard impact resistance, prone to mold |

| Fire Resistance | Enhanced due to fiberglass facing | Standard fire resistance |

| Installation | Easy, no paper tearing or dust | Standard, care needed to prevent paper damage |

| Applications | Wet rooms, bathrooms, commercial areas | Drywall, general interior walls and ceilings |

| Cost | Higher due to specialized materials | Lower, widely available |

Overview of Paperless vs. Paper-Faced Gypsum Board

Paperless gypsum board features a fiberglass mat facing that enhances moisture resistance and mold prevention compared to traditional paper-faced gypsum board, which uses a cellulose paper facing. This difference in facing material makes paperless boards ideal for high-humidity environments such as bathrooms and kitchens. Paper-faced gypsum boards remain popular for general drywall applications due to their cost-effectiveness and ease of installation in dry areas.

Composition and Manufacturing Differences

Paperless gypsum boards are composed of gypsum core reinforced with fiber mats or fiberglass mesh on both sides, eliminating the need for traditional paper facing. Paper-faced gypsum boards consist of a gypsum core encased in heavyweight paper layers, providing surface durability and ease of finishing. Manufacturing paperless boards involves embedding fiberglass reinforcement directly into the core during extrusion, while paper-faced boards are produced by drying the core and laminating paper sheets onto both surfaces in a separate process.

Fire Resistance: Paperless vs. Paper-Faced Gypsum Board

Paperless gypsum boards demonstrate superior fire resistance compared to paper-faced gypsum boards due to their inorganic fiberglass facings that do not burn or support combustion. Paper-faced gypsum boards include cellulose-based paper layers, which can ignite and compromise the fire protection capabilities. Fire-rated assemblies using paperless gypsum effectively enhance building safety by maintaining structural integrity longer during exposure to high temperatures.

Moisture and Mold Resistance Comparison

Paperless gypsum boards exhibit superior moisture resistance by utilizing fiberglass mats instead of traditional paper facings, significantly reducing mold growth potential. Paper-faced gypsum boards are more susceptible to moisture absorption, which can lead to mold development and structural deterioration over time. Enhanced water-resistant additives and fiberglass facings in paperless boards improve durability in high-humidity environments such as bathrooms and basements.

Durability and Lifespan of Each Type

Paperless gypsum boards exhibit superior moisture resistance and enhanced durability compared to traditional paper-faced gypsum boards, resulting in a longer lifespan in humid or high-moisture environments. The fiberglass mesh surface of paperless boards minimizes vulnerability to mold and deterioration, which commonly affect paper-faced gypsum boards over time. Consequently, paperless gypsum boards maintain structural integrity and aesthetic quality significantly longer, reducing maintenance and replacement costs.

Installation Process and Handling

Paperless gypsum board simplifies the installation process by eliminating the risk of paper tearing and reducing moisture absorption, resulting in faster handling and increased durability on-site. Unlike paper-faced gypsum board, paperless versions resist mold and mildew, minimizing damage during storage and transportation while ensuring a more resilient finish. The lightweight nature and enhanced moisture resistance of paperless gypsum boards improve overall handling efficiency and reduce labor costs during installation.

Applications and Best Use Cases

Paperless gypsum boards are highly resistant to moisture, making them ideal for high-humidity areas such as bathrooms, kitchens, and basements, where mold and mildew resistance is critical. Paper-faced gypsum boards are commonly used in standard interior walls and ceilings where easy finishing and painting are required, offering better nail-holding capacity and smooth surface textures. For applications requiring enhanced durability against moisture and impact, paperless gypsum boards provide superior performance, while paper-faced boards are preferred for typical residential and commercial indoor environments.

Environmental Impact and Sustainability

Paperless gypsum boards offer enhanced environmental sustainability by eliminating the need for paper facings, reducing resource consumption and minimizing waste in production and disposal compared to paper-faced gypsum boards. The absence of paper reduces susceptibility to mold and moisture damage, extending the product's lifespan and decreasing the frequency of replacements. Manufacturing paperless boards typically results in lower carbon emissions, aligning with green building practices and LEED certification goals.

Cost Comparison and Value Over Time

Paperless gypsum boards typically have a lower initial cost compared to paper-faced gypsum boards due to reduced material and manufacturing expenses. Over time, paperless boards offer higher value in moisture-prone environments by resisting mold and maintaining structural integrity, decreasing maintenance and replacement costs. Paper-faced gypsum boards may incur hidden expenses related to paper degradation and susceptibility to water damage, impacting long-term cost efficiency.

Industry Standards and Certifications

Paperless gypsum boards are favored in environments requiring enhanced moisture resistance and durability, often meeting ASTM C1396 standards for fire resistance and ASTM C1177 for mold resistance certifications. Paper-faced gypsum boards conform to ASTM C1396 for structural integrity and are widely certified under GREENGUARD for low chemical emissions, supporting indoor air quality standards. Both types adhere to ISO 9001 quality management systems, ensuring consistent manufacturing processes and compliance with regional building codes.

Paperless gypsum board vs Paper-faced gypsum board Infographic

materialdif.com

materialdif.com