Gypsum powder is a finely ground form of gypsum rock, offering faster setting times and greater ease of application in construction and plastering tasks. In contrast, gypsum rock is the raw, natural mineral that requires processing to be transformed into powder, often used as a source material in agriculture and industry. Choosing between gypsum powder and gypsum rock depends on the specific project needs, with powder preferred for immediate use and rock favored for bulk applications or further refinement.

Table of Comparison

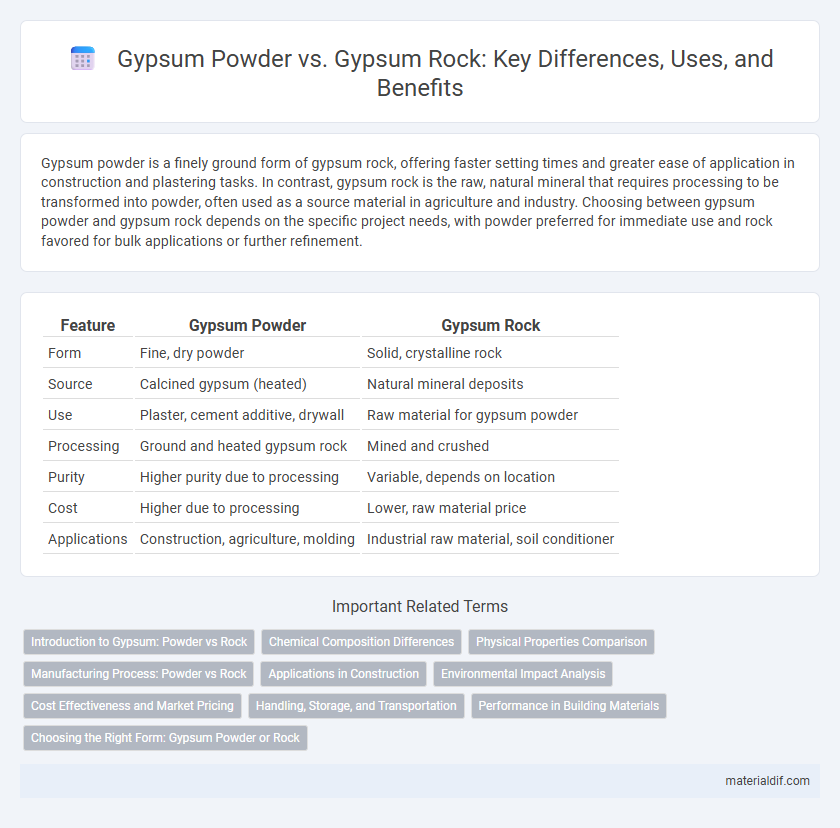

| Feature | Gypsum Powder | Gypsum Rock |

|---|---|---|

| Form | Fine, dry powder | Solid, crystalline rock |

| Source | Calcined gypsum (heated) | Natural mineral deposits |

| Use | Plaster, cement additive, drywall | Raw material for gypsum powder |

| Processing | Ground and heated gypsum rock | Mined and crushed |

| Purity | Higher purity due to processing | Variable, depends on location |

| Cost | Higher due to processing | Lower, raw material price |

| Applications | Construction, agriculture, molding | Industrial raw material, soil conditioner |

Introduction to Gypsum: Powder vs Rock

Gypsum powder is a finely ground form of gypsum rock, widely used in construction for plaster, drywall, and cement additives due to its quick-setting properties and ease of application. Gypsum rock, a natural mineral primarily composed of calcium sulfate dihydrate, is extracted through mining and often processed into powder for industrial and agricultural uses. The key difference lies in their form and usability: gypsum powder offers uniform consistency and faster reactivity, while gypsum rock retains its raw mineral structure suitable for large-scale manufacturing and raw material supply.

Chemical Composition Differences

Gypsum powder primarily consists of calcium sulfate dihydrate (CaSO4*2H2O), obtained by grinding gypsum rock into a fine, uniform consistency, enhancing its reactivity and application. Gypsum rock, a naturally occurring mineral, contains the same chemical compound but may include impurities like silica, clay, or sand, which affect its purity and industrial use. The dehydration process in producing gypsum powder reduces moisture content, resulting in variations in chemical stability and performance between the two forms.

Physical Properties Comparison

Gypsum powder exhibits fine particle size, high surface area, and fast hydration rates, enhancing workability and setting time in construction applications. Gypsum rock, in its natural form, has a coarser texture, lower solubility, and slower reaction kinetics, impacting its direct use efficiency. The density of gypsum powder ranges from 2.3 to 2.4 g/cm3, while gypsum rock density typically measures around 2.31 g/cm3, influencing material handling and mixing properties.

Manufacturing Process: Powder vs Rock

Gypsum powder is produced by heating natural gypsum rock to remove moisture and then grinding it into a fine powder, a process known as calcination. In contrast, gypsum rock is extracted directly from quarries without significant alteration, preserving its natural crystalline form. The manufacturing process of gypsum powder enhances its versatility in construction applications, while gypsum rock is primarily used in its raw state or further processed depending on industrial requirements.

Applications in Construction

Gypsum powder is widely used in construction for creating smooth plaster finishes, drywall boards, and joint compounds due to its fine texture and quick setting properties. Gypsum rock, on the other hand, is primarily utilized as a raw material for manufacturing cement and soil stabilization in large-scale infrastructure projects. Both forms enhance building durability and fire resistance, but gypsum powder offers more versatility in detailed interior applications.

Environmental Impact Analysis

Gypsum powder, produced by grinding and calcining natural gypsum rock, has a lower environmental impact in transportation due to its lightweight and ease of handling compared to bulky gypsum rock. Mining gypsum rock leads to habitat disruption and energy-intensive extraction processes, resulting in higher carbon emissions and soil degradation. Utilizing gypsum powder in construction reduces raw material waste and promotes recycling of by-products such as flue-gas desulfurization gypsum, minimizing overall environmental footprint.

Cost Effectiveness and Market Pricing

Gypsum powder offers greater cost effectiveness than gypsum rock due to its processing efficiency and ease of transportation, reducing overall project expenses. Market pricing of gypsum powder tends to be more stable and affordable as it requires less refinement and bulk handling compared to raw gypsum rock. Construction and agricultural industries favor gypsum powder for its consistent quality and lower price per unit, enhancing budget management and project feasibility.

Handling, Storage, and Transportation

Gypsum powder requires careful handling to avoid dust generation, which can affect air quality and worker safety, while gypsum rock is less prone to airborne particles during transport. Storage of gypsum powder demands moisture-controlled environments to prevent clumping and degradation, whereas gypsum rock is more tolerant to varying humidity levels but must be protected from excessive weather exposure to maintain quality. Transportation of gypsum powder often involves sealed containers or bulk bags to minimize spillage and contamination, compared to gypsum rock that can be transported in open trucks or containers with basic protection measures.

Performance in Building Materials

Gypsum powder offers superior workability and faster setting times compared to gypsum rock, making it ideal for plastering and drywall applications in construction. Its fine particle size ensures better adhesion, smooth finishes, and enhanced fire resistance within building materials. In contrast, gypsum rock requires processing to convert into powder form, limiting its direct use and performance in structural applications.

Choosing the Right Form: Gypsum Powder or Rock

Gypsum powder offers superior workability and faster setting times, making it ideal for plastering and finishing applications, while gypsum rock is primarily used in cement production and as a raw material for manufacturing plaster products. The choice between gypsum powder and rock depends on project requirements, with powder providing ease of mixing and application, whereas rock delivers cost-effective bulk supply for industrial processes. Understanding the specific use case and desired performance characteristics ensures optimal material selection for construction or manufacturing needs.

Gypsum powder vs Gypsum rock Infographic

materialdif.com

materialdif.com