Precast gypsum offers superior control over quality and faster installation times compared to cast-in-place gypsum, which requires on-site mixing and curing. Precast panels provide consistent density and finish, reducing labor costs and minimizing construction delays. Cast-in-place gypsum, on the other hand, offers greater flexibility for customized shapes and seamless integration with complex architectural designs.

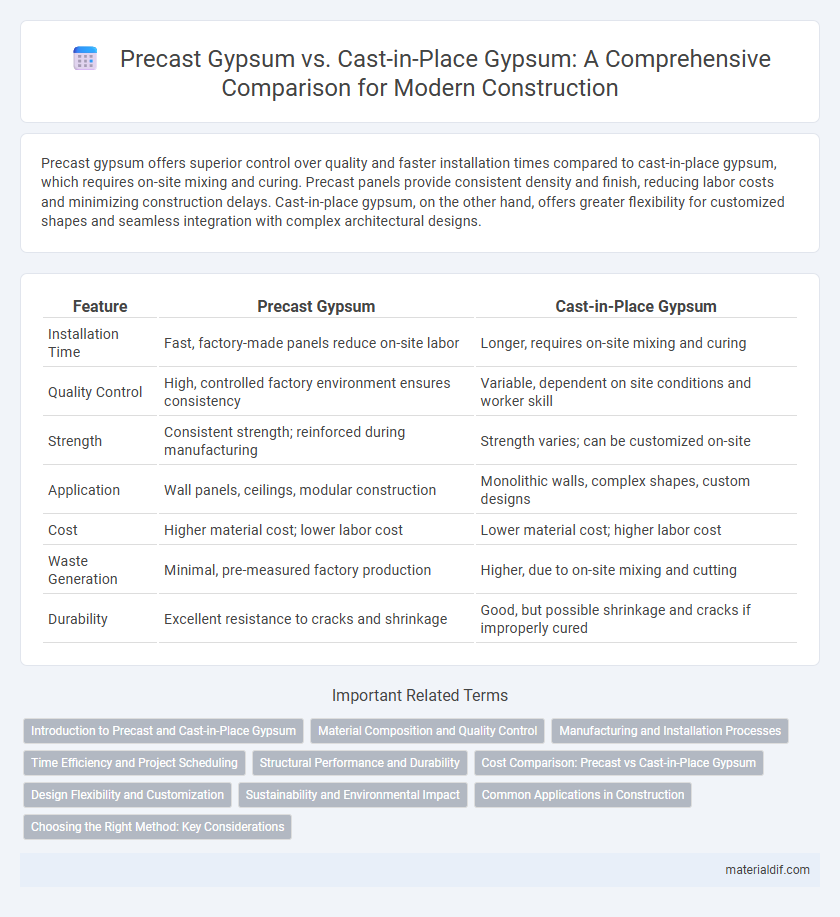

Table of Comparison

| Feature | Precast Gypsum | Cast-in-Place Gypsum |

|---|---|---|

| Installation Time | Fast, factory-made panels reduce on-site labor | Longer, requires on-site mixing and curing |

| Quality Control | High, controlled factory environment ensures consistency | Variable, dependent on site conditions and worker skill |

| Strength | Consistent strength; reinforced during manufacturing | Strength varies; can be customized on-site |

| Application | Wall panels, ceilings, modular construction | Monolithic walls, complex shapes, custom designs |

| Cost | Higher material cost; lower labor cost | Lower material cost; higher labor cost |

| Waste Generation | Minimal, pre-measured factory production | Higher, due to on-site mixing and cutting |

| Durability | Excellent resistance to cracks and shrinkage | Good, but possible shrinkage and cracks if improperly cured |

Introduction to Precast and Cast-in-Place Gypsum

Precast gypsum components are manufactured in controlled factory conditions, ensuring consistent quality and precise dimensions, making them ideal for modular construction and rapid installation. Cast-in-place gypsum involves pouring gypsum slurry directly on-site into molds or forms, allowing for customized shapes and seamless integration within the structure. Both methods offer distinct advantages, with precast gypsum emphasizing speed and uniformity, while cast-in-place gypsum provides design flexibility and adaptability to complex architectural requirements.

Material Composition and Quality Control

Precast gypsum is manufactured under controlled factory conditions, ensuring consistent material composition by precisely blending calcined gypsum, additives, and reinforcing fibers, resulting in uniform density and strength. Cast-in-place gypsum involves on-site mixing of gypsum plaster with water and sometimes additives, which can lead to variability in composition and quality due to environmental factors and manual application. Quality control in precast gypsum is superior due to standardized production processes and rigorous testing, whereas cast-in-place gypsum quality depends largely on skilled workmanship and site conditions.

Manufacturing and Installation Processes

Precast gypsum components are manufactured in controlled factory environments, ensuring consistent quality and precise dimensions, which reduces onsite labor and installation time. Cast-in-place gypsum is mixed and poured directly at the construction site, allowing for customizable shapes but often requiring longer curing times and more complex formwork. The factory production of precast gypsum minimizes waste and enhances structural integrity, while cast-in-place offers flexibility in design and immediate application.

Time Efficiency and Project Scheduling

Precast gypsum panels significantly reduce on-site installation time compared to cast-in-place gypsum, enabling faster project turnover and streamlined scheduling. Factory-controlled conditions for precast gypsum ensure consistent quality and minimize delays caused by weather or site variables. Efficient time management with precast gypsum supports tight construction timelines and lowers labor costs, optimizing overall project delivery.

Structural Performance and Durability

Precast gypsum offers superior structural performance due to factory-controlled conditions ensuring consistent density and strength, making it ideal for load-bearing applications. Cast-in-place gypsum, while adaptable to complex site geometries, may exhibit variable strength and durability because of on-site mixing inconsistencies and moisture exposure during curing. The enhanced durability of precast gypsum results from its lower porosity and improved resistance to cracking compared to cast-in-place counterparts.

Cost Comparison: Precast vs Cast-in-Place Gypsum

Precast gypsum panels typically offer lower labor costs and faster installation times than cast-in-place gypsum due to factory-controlled manufacturing and reduced on-site work. Although initial material costs for precast gypsum may be higher, overall project expenses often decrease because of minimized site delays and labor overhead. Cast-in-place gypsum tends to involve higher labor intensity and longer curing periods, increasing total project costs despite lower material expenses.

Design Flexibility and Customization

Precast gypsum offers high design flexibility through precise factory-controlled molding processes, enabling complex shapes and detailed architectural features with consistent quality. Cast-in-place gypsum allows on-site customization, accommodating last-minute design changes and irregular geometries, but may result in less uniform finishes. Both methods support tailored solutions, with precast excelling in repeatability and cast-in-place providing adaptability to unique project requirements.

Sustainability and Environmental Impact

Precast gypsum offers enhanced sustainability by reducing on-site waste and minimizing energy consumption during installation compared to cast-in-place gypsum, which often involves higher material waste and prolonged curing times. The controlled factory environment of precast gypsum allows for better resource efficiency and recycling of offcuts, significantly lowering the carbon footprint. In contrast, cast-in-place gypsum requires more energy-intensive processes on-site and can generate more dust and emissions, impacting air quality and overall environmental health.

Common Applications in Construction

Precast gypsum panels are widely used in interior wall partitions, ceiling systems, and decorative moldings due to their controlled manufacturing quality and fast installation times. Cast-in-place gypsum is favored for custom architectural shapes, seamless finishes, and on-site adjustments in complex building designs. Both materials provide excellent fire resistance and acoustic performance, making them essential in commercial and residential construction projects.

Choosing the Right Method: Key Considerations

Precast gypsum offers superior quality control, faster installation, and reduced site labor, making it ideal for projects with tight deadlines and consistent design requirements. Cast-in-place gypsum provides customization flexibility and seamless integration with existing structures, suited for complex architectural designs or irregular shapes. Key considerations include project timeline, budget, design complexity, and site conditions to determine the optimal method for efficiency and structural performance.

Precast gypsum vs Cast-in-place gypsum Infographic

materialdif.com

materialdif.com