Gypsum underlayment offers superior moisture resistance and sound dampening compared to concrete underlayment, making it ideal for residential and commercial flooring projects requiring quieter environments. It provides a smoother, more uniform surface that enhances the adhesion and appearance of finished floors, while concrete underlayment is heavier and more durable for high-traffic or industrial spaces. Gypsum's lightweight composition reduces installation time and labor costs, offering an efficient alternative to traditional concrete layers in many construction applications.

Table of Comparison

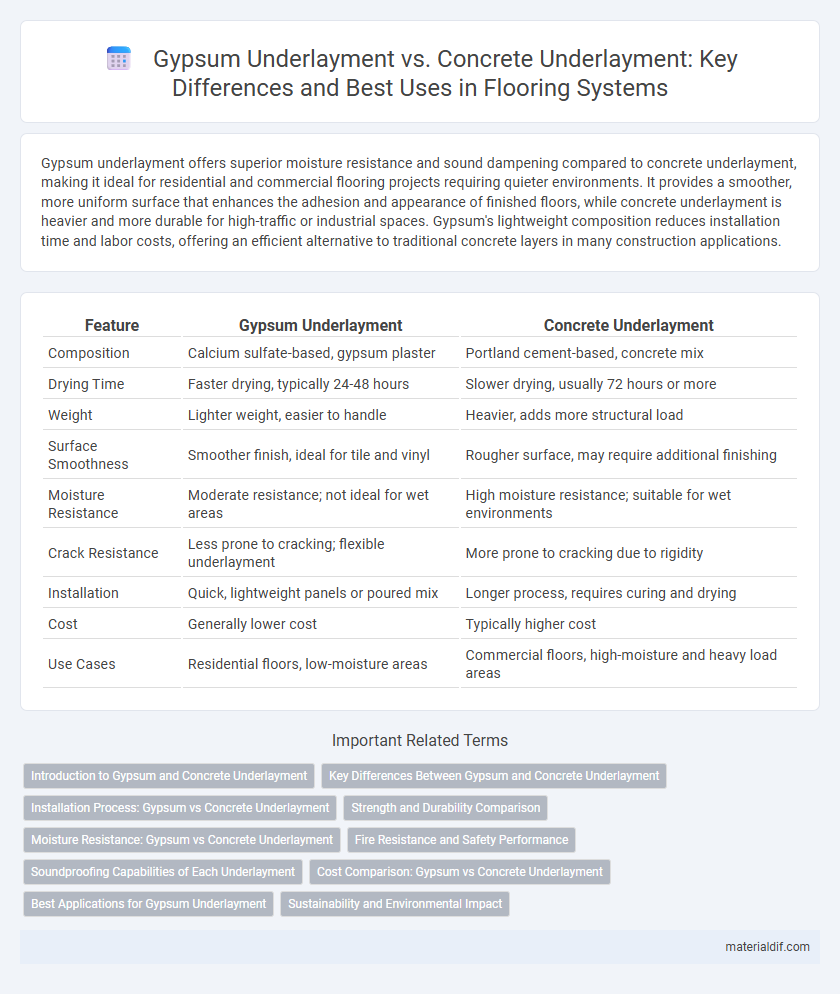

| Feature | Gypsum Underlayment | Concrete Underlayment |

|---|---|---|

| Composition | Calcium sulfate-based, gypsum plaster | Portland cement-based, concrete mix |

| Drying Time | Faster drying, typically 24-48 hours | Slower drying, usually 72 hours or more |

| Weight | Lighter weight, easier to handle | Heavier, adds more structural load |

| Surface Smoothness | Smoother finish, ideal for tile and vinyl | Rougher surface, may require additional finishing |

| Moisture Resistance | Moderate resistance; not ideal for wet areas | High moisture resistance; suitable for wet environments |

| Crack Resistance | Less prone to cracking; flexible underlayment | More prone to cracking due to rigidity |

| Installation | Quick, lightweight panels or poured mix | Longer process, requires curing and drying |

| Cost | Generally lower cost | Typically higher cost |

| Use Cases | Residential floors, low-moisture areas | Commercial floors, high-moisture and heavy load areas |

Introduction to Gypsum and Concrete Underlayment

Gypsum underlayment is a cementitious material composed of calcium sulfate dihydrate, offering a smooth, moisture-resistant surface ideal for tile and hardwood floor installations. Concrete underlayment, typically a cement-based mixture containing aggregates and additives, provides a durable, high-strength base suitable for heavy traffic and structural reinforcement. Both materials serve as foundational layers but differ in composition, drying time, and application suitability depending on project requirements and environmental conditions.

Key Differences Between Gypsum and Concrete Underlayment

Gypsum underlayment offers faster drying times and smoother finishes compared to concrete underlayment, making it ideal for residential and commercial flooring applications requiring quick installation. Concrete underlayment provides superior durability, moisture resistance, and load-bearing capacity, which suit industrial or high-traffic environments. Differences in composition, curing process, and performance attributes determine the appropriate choice for specific project requirements.

Installation Process: Gypsum vs Concrete Underlayment

Gypsum underlayment offers a faster installation process due to its lighter weight and ability to be poured or pumped easily over large areas, reducing labor time compared to concrete. Concrete underlayment requires more preparation, mixing, and curing time, often involving reinforced mesh and thicker layers for durability. Gypsum's rapid drying time accelerates subsequent flooring installation, making it ideal for projects needing quick turnaround.

Strength and Durability Comparison

Gypsum underlayment offers a smooth and moisture-resistant surface ideal for indoor applications but generally lacks the high compressive strength of concrete underlayment, which provides superior load-bearing capacity and long-term durability. Concrete underlayment excels in resistance to cracking and wear under heavy traffic, making it preferable for industrial and commercial flooring where strength is critical. While gypsum underlayment cures quickly and provides excellent fire resistance, concrete's enhanced structural integrity makes it the optimal choice for projects demanding maximum strength and durability.

Moisture Resistance: Gypsum vs Concrete Underlayment

Gypsum underlayment offers limited moisture resistance and is susceptible to damage in high-humidity environments, making it less suitable for areas prone to moisture exposure. Concrete underlayment provides superior moisture resistance due to its dense, non-porous composition, effectively preventing water infiltration and mold growth. Choosing concrete underlayment is critical for subfloor applications in bathrooms, basements, and other moisture-prone areas to ensure durability and longevity.

Fire Resistance and Safety Performance

Gypsum underlayment offers superior fire resistance due to its non-combustible properties and ability to slow heat transfer, making it an excellent choice for enhancing building safety. In contrast, concrete underlayment, while durable and strong, lacks the same level of fire retardant capabilities and may contribute to faster heat conduction during a fire event. Gypsum's inherent fire-resistant chemicals improve occupant protection and structural integrity, meeting stringent fire safety codes in residential and commercial applications.

Soundproofing Capabilities of Each Underlayment

Gypsum underlayment offers superior soundproofing capabilities due to its dense and porous structure that effectively absorbs sound waves and reduces impact noise. Concrete underlayment provides moderate sound insulation but tends to transmit higher frequencies more readily because of its rigid and solid composition. For applications prioritizing noise reduction, gypsum underlayment is often preferred in residential and commercial flooring systems for enhanced acoustic performance.

Cost Comparison: Gypsum vs Concrete Underlayment

Gypsum underlayment typically costs between $1.50 and $3.00 per square foot, making it a more affordable option compared to concrete underlayment, which ranges from $2.50 to $5.00 per square foot. Gypsum offers quicker installation and drying times, reducing labor costs, while concrete requires longer curing periods that can delay project timelines and increase expenses. Material choices should consider both the upfront cost and potential savings in labor and project duration when selecting between gypsum and concrete underlayments.

Best Applications for Gypsum Underlayment

Gypsum underlayment excels in interior applications requiring a smooth, level surface suitable for finished flooring such as vinyl, carpet, or tile, especially where weight considerations are important. It offers superior crack resistance and faster drying times compared to concrete underlayment, making it ideal for residential and commercial renovation projects. Gypsum's fire-resistant properties and sound control benefits enhance its performance in multi-story buildings and areas with strict building codes.

Sustainability and Environmental Impact

Gypsum underlayment offers a more sustainable option compared to concrete underlayment due to its lower carbon footprint and the ability to use recycled materials in its production. Gypsum is a natural mineral that is abundant and minimizes environmental degradation, whereas concrete manufacturing releases significant CO2 contributing to global warming. Additionally, gypsum underlayment is often recyclable and reduces landfill waste, enhancing its environmental benefits over traditional concrete underlayment.

Gypsum underlayment vs Concrete underlayment Infographic

materialdif.com

materialdif.com