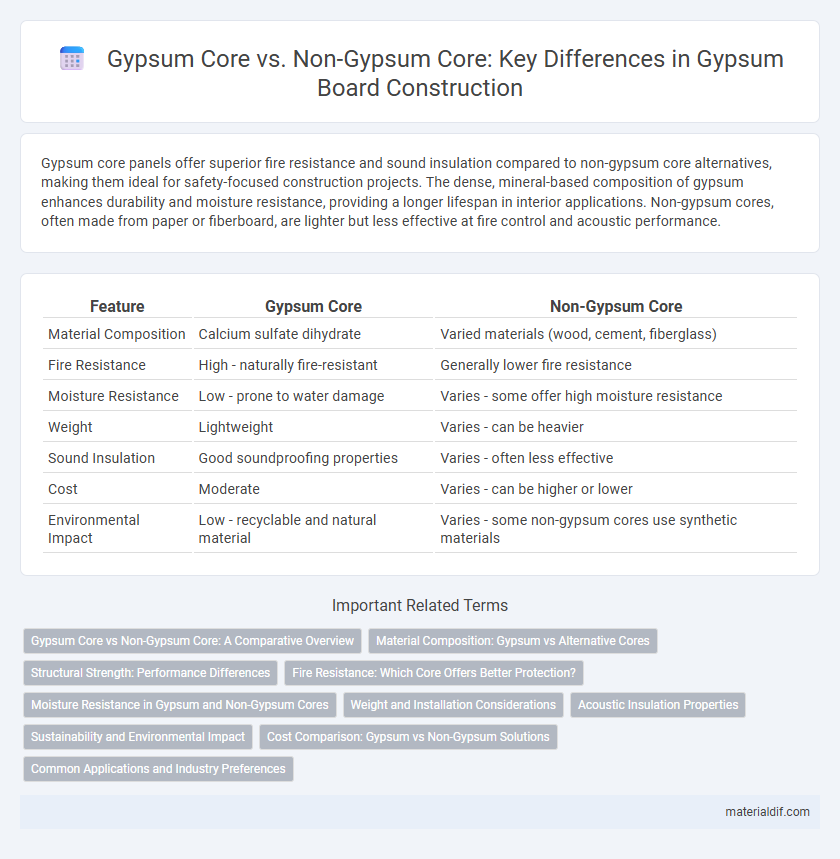

Gypsum core panels offer superior fire resistance and sound insulation compared to non-gypsum core alternatives, making them ideal for safety-focused construction projects. The dense, mineral-based composition of gypsum enhances durability and moisture resistance, providing a longer lifespan in interior applications. Non-gypsum cores, often made from paper or fiberboard, are lighter but less effective at fire control and acoustic performance.

Table of Comparison

| Feature | Gypsum Core | Non-Gypsum Core |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate | Varied materials (wood, cement, fiberglass) |

| Fire Resistance | High - naturally fire-resistant | Generally lower fire resistance |

| Moisture Resistance | Low - prone to water damage | Varies - some offer high moisture resistance |

| Weight | Lightweight | Varies - can be heavier |

| Sound Insulation | Good soundproofing properties | Varies - often less effective |

| Cost | Moderate | Varies - can be higher or lower |

| Environmental Impact | Low - recyclable and natural material | Varies - some non-gypsum cores use synthetic materials |

Gypsum Core vs Non-Gypsum Core: A Comparative Overview

Gypsum core panels offer superior fire resistance, sound insulation, and moisture regulation compared to non-gypsum cores, making them ideal for residential and commercial construction. Non-gypsum core materials, such as fiberglass or foam, typically provide enhanced lightweight properties and flexibility but may lack the durability and environmental benefits of gypsum. Selecting between gypsum core and non-gypsum core depends on project-specific requirements like fire safety standards, acoustic performance, and budget constraints.

Material Composition: Gypsum vs Alternative Cores

Gypsum core panels are primarily composed of calcium sulfate dihydrate, providing excellent fire resistance and sound insulation due to its natural mineral properties. Non-gypsum cores often utilize materials like fiberglass, MDF, or recycled wood fibers, which offer enhanced moisture resistance and structural strength but may lack the inherent fire-retardant capabilities of gypsum. The choice between gypsum and alternative cores hinges on balancing fire safety, durability, and environmental factors specific to construction requirements.

Structural Strength: Performance Differences

Gypsum core drywall provides improved fire resistance and sound attenuation compared to non-gypsum core materials, enhancing overall structural safety. The dense, chemically bonded core of gypsum offers superior rigidity and load-bearing capacity, making it less prone to sagging or warping under stress. In contrast, non-gypsum cores, such as fiberboard or cement, may lack consistent strength and durability, leading to potential weaknesses in structural applications.

Fire Resistance: Which Core Offers Better Protection?

Gypsum core drywall provides superior fire resistance due to its non-combustible core composed of calcium sulfate dihydrate, which releases water vapor when exposed to heat, slowing fire spread. Non-gypsum cores, such as paper or fiberglass, lack this inherent fire-resistant property and are more susceptible to ignition and structural compromise during a fire. Therefore, gypsum core panels are widely preferred in construction for enhancing fire safety and meeting building code fire ratings.

Moisture Resistance in Gypsum and Non-Gypsum Cores

Gypsum core boards offer superior moisture resistance compared to non-gypsum cores due to their natural ability to absorb and release humidity, preventing mold growth and structural damage. Non-gypsum cores, often made from materials like wood or fiberglass, are more susceptible to moisture absorption, leading to swelling, warping, and reduced durability over time. Moisture-resistant gypsum cores are typically enhanced with additives such as fiberglass matting and water-repellent treatments, improving their performance in humid environments.

Weight and Installation Considerations

Gypsum core drywall is lighter compared to non-gypsum core materials, reducing overall structural load and simplifying handling during installation. This lighter weight facilitates faster installation, minimizing labor costs and fatigue for workers. Non-gypsum cores, often denser or reinforced, may provide enhanced impact resistance but require more effort and time to install due to increased weight.

Acoustic Insulation Properties

Gypsum core panels provide superior acoustic insulation due to their dense, sound-absorbing structure, effectively reducing noise transmission between rooms. Non-gypsum core materials, such as fiberglass or mineral wool, often rely on porous, fibrous composition to dampen sound but may lack the combined fire resistance and structural integrity offered by gypsum. Selecting gypsum core products enhances soundproofing performance in residential and commercial construction by balancing sound reduction and durability.

Sustainability and Environmental Impact

Gypsum core panels demonstrate superior sustainability due to their recyclability and minimal environmental footprint during production compared to non-gypsum cores, which often rely on synthetic or less eco-friendly materials. The natural composition of gypsum allows for energy-efficient manufacturing and end-of-life reuse, significantly reducing landfill waste and harmful emissions. Non-gypsum cores typically involve higher embodied carbon and limited recyclability, increasing environmental impact throughout their lifecycle.

Cost Comparison: Gypsum vs Non-Gypsum Solutions

Gypsum core panels generally offer a more cost-effective solution due to the lower price of raw gypsum materials and efficient manufacturing processes compared to non-gypsum cores such as fiberglass or cement-based alternatives. Non-gypsum core products often incur higher costs influenced by more expensive raw materials, increased fabrication complexity, and enhanced durability features. Overall, gypsum core solutions provide a competitive balance of affordability and performance, making them preferred in budget-sensitive construction projects.

Common Applications and Industry Preferences

Gypsum core panels dominate the construction industry for interior drywall applications due to their fire resistance, sound attenuation, and cost-effectiveness in residential and commercial buildings. Non-gypsum core boards, often featuring materials like cement or magnesium oxide, are preferred in environments requiring higher moisture resistance and durability, such as exterior sheathing or wet areas in hospitals and kitchens. Industry preferences favor gypsum core for standard wall and ceiling assemblies, while specialized sectors select non-gypsum cores to meet stringent performance criteria in harsh or load-bearing conditions.

Gypsum core vs Non-gypsum core Infographic

materialdif.com

materialdif.com