Gypsum casting offers fine detail and rapid setting times, making it ideal for decorative elements and intricate molds, while concrete casting provides superior strength and durability for structural applications. Gypsum is lightweight and easier to shape, but it lacks the toughness and weather resistance of concrete. Concrete casting is preferred for load-bearing constructions, whereas gypsum is suited for interior design features and prototypes.

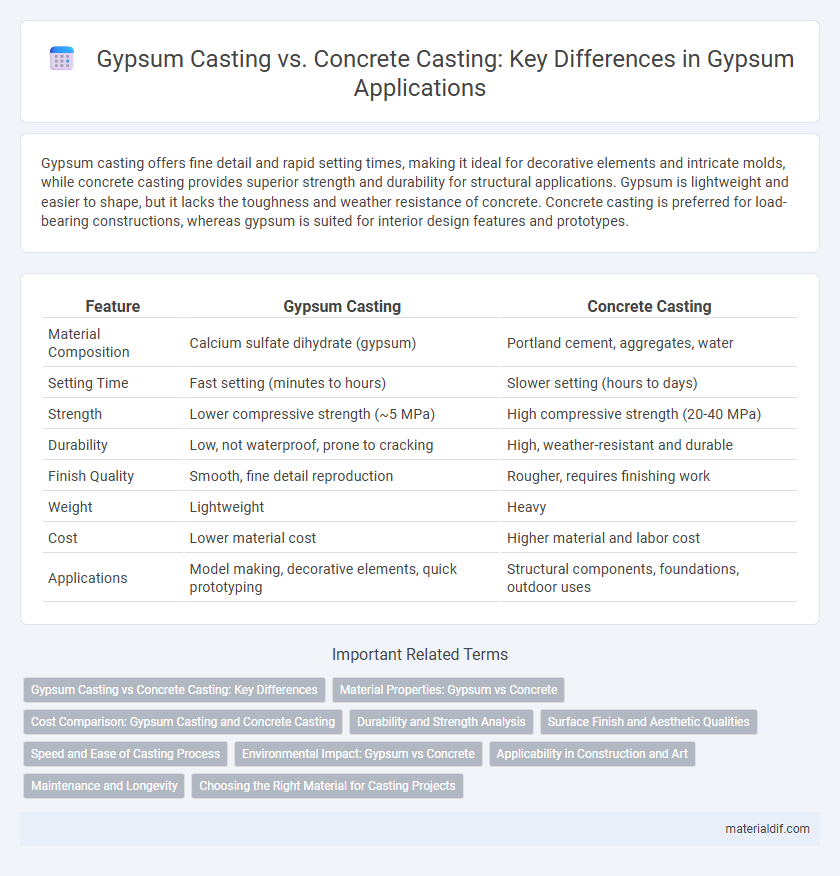

Table of Comparison

| Feature | Gypsum Casting | Concrete Casting |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate (gypsum) | Portland cement, aggregates, water |

| Setting Time | Fast setting (minutes to hours) | Slower setting (hours to days) |

| Strength | Lower compressive strength (~5 MPa) | High compressive strength (20-40 MPa) |

| Durability | Low, not waterproof, prone to cracking | High, weather-resistant and durable |

| Finish Quality | Smooth, fine detail reproduction | Rougher, requires finishing work |

| Weight | Lightweight | Heavy |

| Cost | Lower material cost | Higher material and labor cost |

| Applications | Model making, decorative elements, quick prototyping | Structural components, foundations, outdoor uses |

Gypsum Casting vs Concrete Casting: Key Differences

Gypsum casting offers finer detail and faster setting times compared to concrete casting, making it ideal for intricate molds and decorative elements. Concrete casting provides superior strength and durability, suitable for structural applications and outdoor use. Unlike concrete, gypsum casting is more brittle and less resistant to moisture, limiting its use in load-bearing and exterior environments.

Material Properties: Gypsum vs Concrete

Gypsum casting offers faster setting times and smoother surface finishes compared to concrete casting, making it ideal for detailed mold work and decorative elements. In contrast, concrete provides superior compressive strength and durability, suited for structural applications and outdoor environments. While gypsum has lower resistance to moisture and mechanical stress, concrete's dense matrix ensures long-term performance under heavy loads and adverse weather conditions.

Cost Comparison: Gypsum Casting and Concrete Casting

Gypsum casting typically incurs lower material costs than concrete casting due to gypsum's affordability and ease of handling. Labor expenses for gypsum casting are also generally reduced because of its faster setting time and simpler mold preparation. Overall, gypsum casting offers a cost-effective alternative for detailed molds, while concrete casting demands higher investment for durable and structural applications.

Durability and Strength Analysis

Gypsum casting exhibits lower durability and compressive strength compared to concrete casting, making it less suitable for structural applications requiring long-term load-bearing capacity. Concrete's hydraulic cement matrix provides superior resistance to weathering, chemical attack, and mechanical stress, resulting in enhanced durability and strength. While gypsum casting is ideal for detailed architectural molds and decorative elements, concrete casting remains the preferred choice for robust construction projects.

Surface Finish and Aesthetic Qualities

Gypsum casting produces a smoother and more detailed surface finish compared to concrete casting, allowing for intricate designs and fine textures ideal for decorative elements. The material's fine particle size and quick setting time contribute to its ability to replicate sharp details and a polished appearance. Concrete casting typically results in a rougher texture and requires additional finishing processes to achieve similar aesthetic qualities.

Speed and Ease of Casting Process

Gypsum casting offers significantly faster setting times than concrete, allowing molds to be demolded within hours instead of days. The material's fine particle size and smooth texture make the casting process easier, requiring less vibration and finishing work. Concrete casting demands longer curing periods and more complex handling due to its coarse aggregate and water content.

Environmental Impact: Gypsum vs Concrete

Gypsum casting generates significantly lower carbon emissions compared to concrete casting due to its lower energy-intensive production process and use of natural mineral resources. Concrete casting relies heavily on cement, which accounts for approximately 8% of global CO2 emissions, whereas gypsum plaster produces minimal greenhouse gases and is often sourced from industrial byproducts like flue-gas desulfurization. Gypsum is also more recyclable and biodegradable, reducing landfill waste and environmental degradation compared to the long-lasting non-biodegradable nature of concrete.

Applicability in Construction and Art

Gypsum casting offers superior detail and smooth finishes making it ideal for intricate art sculptures and architectural decorations, while concrete casting excels in structural applications requiring high durability and load-bearing capacity. Gypsum's quick setting time and ease of molding favor ornamental and interior elements, whereas concrete's robustness suits foundations, walls, and outdoor infrastructure. Both materials serve unique roles in construction and art, with gypsum prioritizing aesthetics and concrete emphasizing strength.

Maintenance and Longevity

Gypsum casting requires less maintenance due to its smooth surface and resistance to mold and mildew, but it is more susceptible to water damage and structural wear over time compared to concrete casting. Concrete casting offers superior longevity with its high durability and resistance to environmental factors like moisture, temperature fluctuations, and heavy loads. While gypsum is ideal for decorative elements with lower exposure, concrete remains the preferred material for structural components needing extended lifespan and minimal upkeep.

Choosing the Right Material for Casting Projects

Gypsum casting offers superior detail reproduction and faster setting times compared to concrete casting, making it ideal for intricate molds and indoor applications. Concrete casting provides greater strength and durability, suitable for structural elements and outdoor projects exposed to weathering. Selecting between gypsum and concrete depends on project requirements for finish quality, mechanical properties, and environmental conditions.

Gypsum casting vs Concrete casting Infographic

materialdif.com

materialdif.com