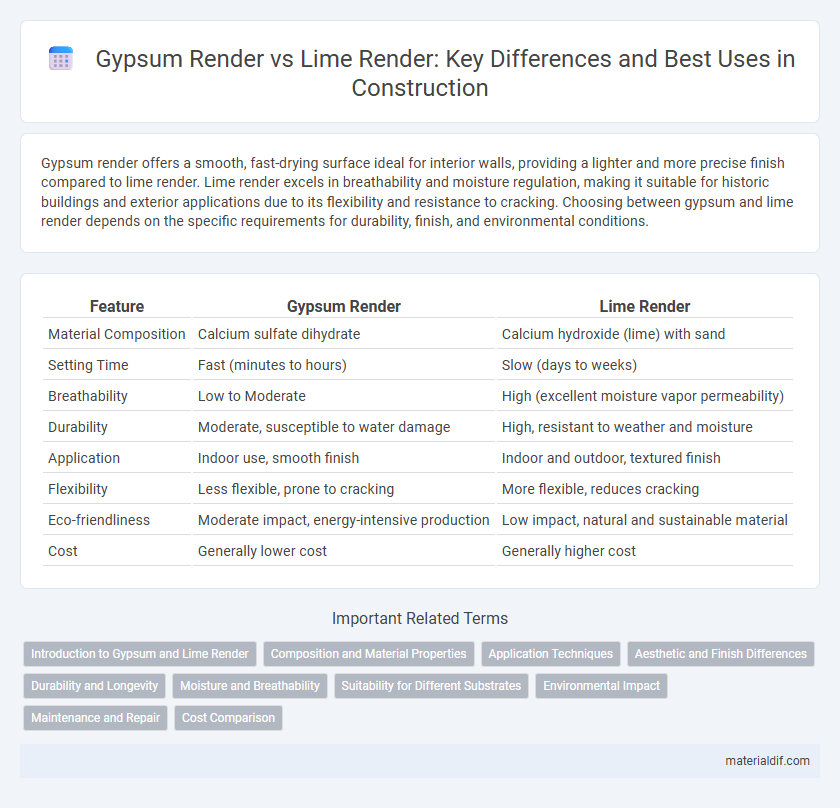

Gypsum render offers a smooth, fast-drying surface ideal for interior walls, providing a lighter and more precise finish compared to lime render. Lime render excels in breathability and moisture regulation, making it suitable for historic buildings and exterior applications due to its flexibility and resistance to cracking. Choosing between gypsum and lime render depends on the specific requirements for durability, finish, and environmental conditions.

Table of Comparison

| Feature | Gypsum Render | Lime Render |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate | Calcium hydroxide (lime) with sand |

| Setting Time | Fast (minutes to hours) | Slow (days to weeks) |

| Breathability | Low to Moderate | High (excellent moisture vapor permeability) |

| Durability | Moderate, susceptible to water damage | High, resistant to weather and moisture |

| Application | Indoor use, smooth finish | Indoor and outdoor, textured finish |

| Flexibility | Less flexible, prone to cracking | More flexible, reduces cracking |

| Eco-friendliness | Moderate impact, energy-intensive production | Low impact, natural and sustainable material |

| Cost | Generally lower cost | Generally higher cost |

Introduction to Gypsum and Lime Render

Gypsum render, composed primarily of calcium sulfate dihydrate, offers a smooth, fine finish ideal for interior walls due to its quick setting and moisture-resistant properties, enhancing surface durability and aesthetic appeal. Lime render, made from calcium hydroxide, provides excellent breathability and flexibility, making it suitable for older buildings by allowing moisture to evaporate and preventing structural damage. Both renders play crucial roles in construction, with gypsum favoring rapid application and modern interiors, while lime supports traditional masonry with its natural antifungal and weather-resistant qualities.

Composition and Material Properties

Gypsum render consists primarily of calcium sulfate dihydrate, offering fast setting and smooth finishes ideal for interior surfaces. Lime render is made from calcium hydroxide, known for its breathability, flexibility, and resistance to moisture, making it suitable for exterior applications. The hygroscopic nature of gypsum allows quick moisture absorption, whereas lime's porous structure facilitates vapor permeability and durability over time.

Application Techniques

Gypsum render offers quick setting times and smooth finishes, making it ideal for interior walls and detailed decorative work. Lime render requires multiple coat applications with longer curing times, suitable for external surfaces due to its breathability and flexibility. Techniques for gypsum involve fine troweling and sanding, whereas lime render demands layering and consistent moisture control to prevent cracking.

Aesthetic and Finish Differences

Gypsum render provides a smooth, polished finish that enhances interior walls with a bright, clean aesthetic, making it ideal for modern, contemporary designs. Lime render, by contrast, offers a matte, textured surface that contributes to a rustic, traditional look while promoting breathability and natural weather resistance. The choice between gypsum render and lime render significantly influences the final appearance and feel of a space, with gypsum emphasizing sleekness and lime emphasizing natural character.

Durability and Longevity

Gypsum render offers smooth finishes but lacks the durability and longevity of lime render, as gypsum is more susceptible to moisture damage and cracking over time. Lime render's natural breathability and flexibility enhance its resistance to weathering, promoting longer-lasting protection for building facades. Buildings treated with lime render often require less frequent maintenance, making it a superior choice for durability in varied climatic conditions.

Moisture and Breathability

Gypsum render offers a smooth finish but has limited moisture resistance and lower breathability compared to lime render. Lime render excels in moisture regulation by allowing walls to breathe and preventing dampness buildup through its porous structure. This makes lime render a superior choice for environments prone to humidity and moisture exposure.

Suitability for Different Substrates

Gypsum render is highly suitable for interior walls and ceilings due to its smooth finish and rapid drying properties, making it ideal for drywall and plasterboard substrates. Lime render excels on exterior masonry surfaces like brick and stone, offering superior breathability and flexibility that accommodate substrate movement and moisture variations. Selecting between gypsum and lime render depends on substrate type, environmental exposure, and required durability of the finish.

Environmental Impact

Gypsum render produces lower carbon emissions during manufacturing compared to lime render, making it a more eco-friendly choice for reducing environmental footprints in construction. Lime render offers natural breathability and carbon sequestration through atmospheric CO2 absorption during curing, contributing to sustainable building practices. Both materials have distinct environmental benefits, with gypsum supporting energy-efficient production and lime enhancing long-term air quality and durability.

Maintenance and Repair

Gypsum render requires less frequent maintenance compared to lime render due to its faster drying time and resistance to cracking, which reduces repair needs. Lime render, while more breathable and flexible, demands regular upkeep to prevent erosion and lime wash deterioration, often requiring patching or reapplication. Repairing gypsum render typically involves simple filling and sanding, whereas lime render repairs may necessitate matching the original lime composition to maintain adhesion and breathability.

Cost Comparison

Gypsum render typically costs more than lime render due to its synthetic production and quicker setting time, with prices averaging around $15 to $25 per square meter compared to lime render's $10 to $18 per square meter. Lime render involves longer curing periods and traditional application methods, which can reduce labor expenses but increase overall project duration and associated costs. Budget considerations often favor lime render for affordable and sustainable options, while gypsum renders are chosen for faster project completion despite higher material expenses.

Gypsum render vs Lime render Infographic

materialdif.com

materialdif.com