Lightweight gypsum offers superior ease of handling and faster installation compared to traditional gypsum due to its reduced density and enhanced formulation. It provides improved thermal and acoustic insulation, making it an ideal choice for modern construction projects aiming for energy efficiency. Despite its lighter weight, lightweight gypsum maintains comparable strength and durability, ensuring reliable performance in wall and ceiling applications.

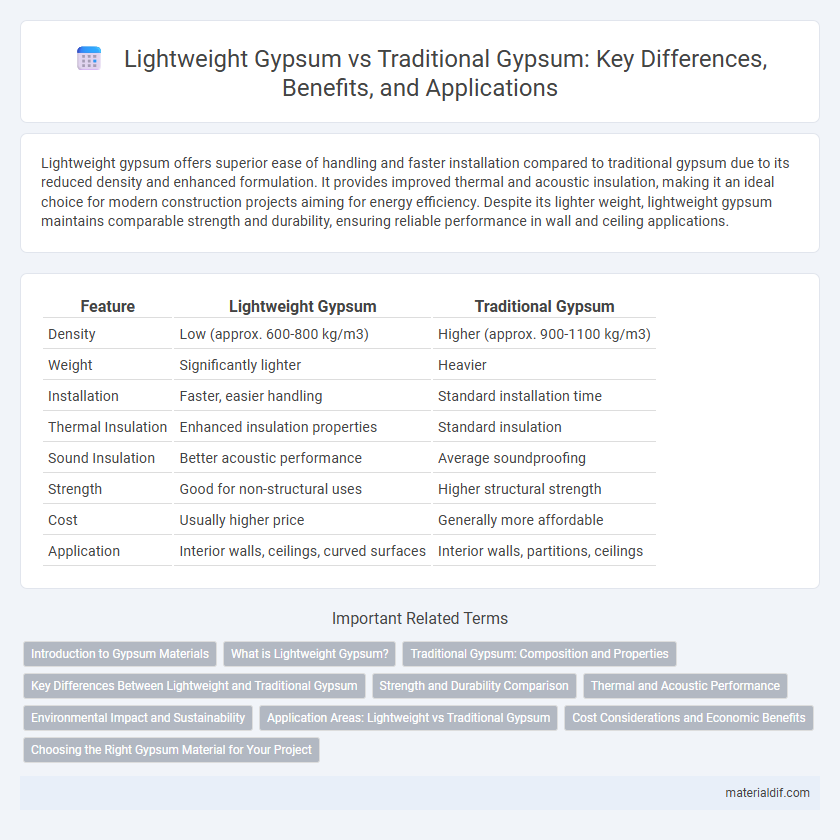

Table of Comparison

| Feature | Lightweight Gypsum | Traditional Gypsum |

|---|---|---|

| Density | Low (approx. 600-800 kg/m3) | Higher (approx. 900-1100 kg/m3) |

| Weight | Significantly lighter | Heavier |

| Installation | Faster, easier handling | Standard installation time |

| Thermal Insulation | Enhanced insulation properties | Standard insulation |

| Sound Insulation | Better acoustic performance | Average soundproofing |

| Strength | Good for non-structural uses | Higher structural strength |

| Cost | Usually higher price | Generally more affordable |

| Application | Interior walls, ceilings, curved surfaces | Interior walls, partitions, ceilings |

Introduction to Gypsum Materials

Lightweight gypsum offers enhanced workability and reduced density compared to traditional gypsum, making it ideal for applications requiring easier handling and faster installation. Traditional gypsum materials typically provide greater structural strength and sound insulation, suitable for load-bearing walls and durable finishes. Both types of gypsum are composed primarily of calcium sulfate dihydrate, but lightweight variants incorporate additives to improve performance in specific construction scenarios.

What is Lightweight Gypsum?

Lightweight gypsum is a type of gypsum board engineered with additives and expanded fillers to reduce density while maintaining strength and fire resistance. It offers improved workability and faster installation compared to traditional gypsum, making it ideal for ceilings and partitions where weight reduction is critical. Its enhanced thermal and acoustic properties also contribute to better building performance without compromising durability.

Traditional Gypsum: Composition and Properties

Traditional gypsum consists primarily of calcium sulfate dihydrate (CaSO4*2H2O), providing strong binding properties and durability. Its dense structure results in higher weight and enhanced fire resistance compared to lightweight gypsum. This material's thermal insulation is moderate, making it suitable for robust construction and interior finishing applications.

Key Differences Between Lightweight and Traditional Gypsum

Lightweight gypsum contains additives or air bubbles that reduce its density, making it easier to handle and install compared to traditional gypsum, which is denser and heavier. Traditional gypsum offers superior sound insulation and fire resistance due to its solid composition, while lightweight gypsum sacrifices some of these properties for enhanced flexibility and reduced weight. The choice between lightweight and traditional gypsum hinges on project requirements such as load-bearing capacity, acoustic performance, and ease of installation.

Strength and Durability Comparison

Lightweight gypsum offers improved handling and faster installation but generally exhibits lower compressive strength and durability compared to traditional gypsum. Traditional gypsum boards provide superior fire resistance and moisture durability, making them ideal for high-stress environments and long-term structural applications. The choice between lightweight and traditional gypsum hinges on balancing ease of use with the required strength and longevity for specific construction projects.

Thermal and Acoustic Performance

Lightweight gypsum offers superior thermal insulation due to its porous structure, reducing heat transfer and enhancing energy efficiency compared to traditional gypsum. Its acoustic performance is also improved, providing better sound absorption and noise reduction in interior spaces. Traditional gypsum, while durable, typically exhibits lower insulation and soundproofing capabilities.

Environmental Impact and Sustainability

Lightweight gypsum significantly reduces environmental impact by using fewer raw materials and lowering energy consumption during manufacturing compared to traditional gypsum. Its improved thermal insulation properties contribute to energy efficiency in buildings, reducing overall carbon footprints. Sustainable production methods and enhanced recyclability make lightweight gypsum a preferable choice for eco-friendly construction.

Application Areas: Lightweight vs Traditional Gypsum

Lightweight gypsum is widely used in interior partitions, ceilings, and decorative elements due to its reduced weight and ease of handling, making it ideal for renovation projects and areas requiring quick installation. Traditional gypsum, known for its high density and durability, is preferred in construction zones requiring enhanced sound insulation, fire resistance, and structural strength, such as load-bearing walls and commercial buildings. Application selection depends on balancing weight considerations with performance requirements in residential, commercial, and industrial environments.

Cost Considerations and Economic Benefits

Lightweight gypsum panels often reduce transportation and installation costs due to their lower density, leading to decreased labor expenses and faster project timelines compared to traditional gypsum. Although traditional gypsum sheets are usually less expensive per unit, the overall project cost can be higher because of increased handling difficulty and longer installation times. Choosing lightweight gypsum can offer economic benefits by minimizing structural support requirements and enhancing energy efficiency, which contribute to long-term savings.

Choosing the Right Gypsum Material for Your Project

Lightweight gypsum offers enhanced workability and reduced structural load compared to traditional gypsum, making it ideal for ceilings and partitions where ease of installation and weight savings are crucial. Traditional gypsum provides superior density and sound insulation, making it suitable for walls and areas requiring robustness and durability. Selecting the right gypsum material depends on project requirements such as load capacity, acoustic performance, and installation efficiency.

Lightweight gypsum vs Traditional gypsum Infographic

materialdif.com

materialdif.com