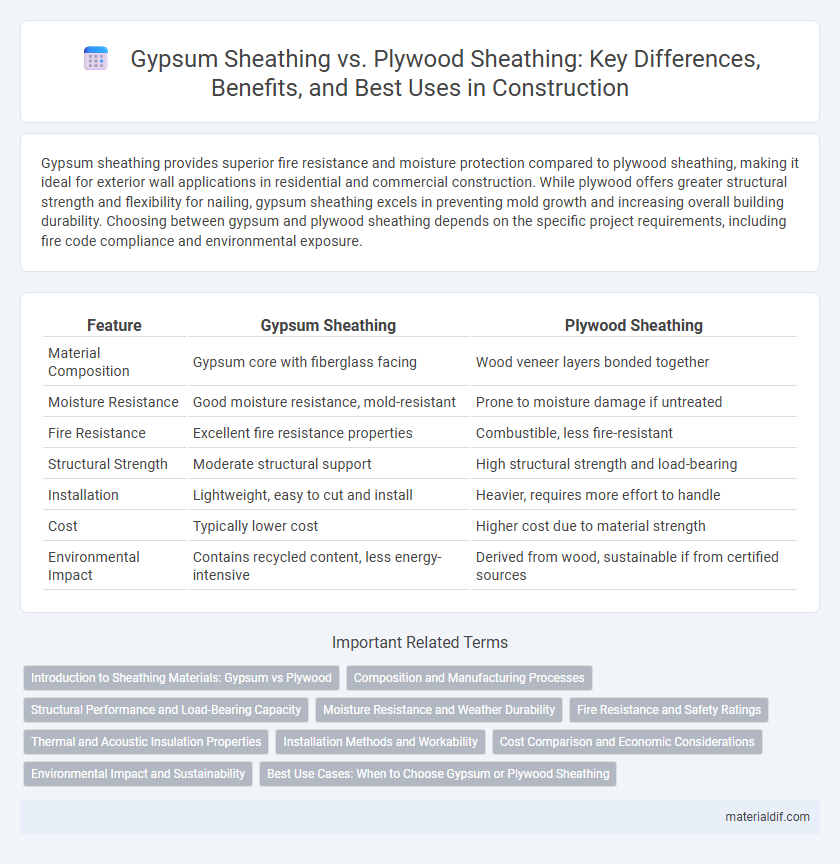

Gypsum sheathing provides superior fire resistance and moisture protection compared to plywood sheathing, making it ideal for exterior wall applications in residential and commercial construction. While plywood offers greater structural strength and flexibility for nailing, gypsum sheathing excels in preventing mold growth and increasing overall building durability. Choosing between gypsum and plywood sheathing depends on the specific project requirements, including fire code compliance and environmental exposure.

Table of Comparison

| Feature | Gypsum Sheathing | Plywood Sheathing |

|---|---|---|

| Material Composition | Gypsum core with fiberglass facing | Wood veneer layers bonded together |

| Moisture Resistance | Good moisture resistance, mold-resistant | Prone to moisture damage if untreated |

| Fire Resistance | Excellent fire resistance properties | Combustible, less fire-resistant |

| Structural Strength | Moderate structural support | High structural strength and load-bearing |

| Installation | Lightweight, easy to cut and install | Heavier, requires more effort to handle |

| Cost | Typically lower cost | Higher cost due to material strength |

| Environmental Impact | Contains recycled content, less energy-intensive | Derived from wood, sustainable if from certified sources |

Introduction to Sheathing Materials: Gypsum vs Plywood

Gypsum sheathing offers superior fire resistance and moisture tolerance compared to traditional plywood sheathing, making it ideal for exterior wall applications where enhanced protection is required. Plywood sheathing provides structural strength and flexibility, often used in framing to support siding and roofing while contributing to overall building stability. Choosing between gypsum and plywood sheathing depends on project requirements for fire safety, moisture resistance, and structural support in construction.

Composition and Manufacturing Processes

Gypsum sheathing is composed primarily of gypsum plaster encased in fiberglass mats, produced through a calcination process where natural gypsum is heated to remove water content and then combined with additives for fire resistance and moisture control. Plywood sheathing consists of thin layers of wood veneers glued together with waterproof adhesives, created by pressing and bonding wood veneers under heat and pressure to form durable, flexible panels. The distinct manufacturing processes result in gypsum sheathing offering superior fire resistance and moisture control, while plywood sheathing provides higher structural strength and impact resistance.

Structural Performance and Load-Bearing Capacity

Gypsum sheathing offers superior fire resistance and moisture control compared to plywood sheathing, enhancing building safety and durability. Plywood sheathing provides higher structural performance with greater load-bearing capacity, making it ideal for wall and roof applications where strength is critical. The choice between gypsum and plywood sheathing depends on project requirements balancing fire protection and structural demands.

Moisture Resistance and Weather Durability

Gypsum sheathing offers superior moisture resistance compared to plywood sheathing due to its inorganic core, which reduces susceptibility to water damage and mold growth. Plywood sheathing tends to absorb moisture, leading to swelling, warping, and reduced structural integrity over time. Gypsum's enhanced weather durability makes it a preferred choice in climates with high humidity or frequent precipitation, ensuring longer-lasting protection for building envelopes.

Fire Resistance and Safety Ratings

Gypsum sheathing offers superior fire resistance compared to plywood sheathing due to its non-combustible composition and inherent ability to slow heat transfer. Fire safety ratings for gypsum sheathing typically range from Class A to Class C, with many gypsum products achieving Class A ratings for the highest flame spread resistance. In contrast, plywood sheathing is combustible and generally requires additional fire-retardant treatments to meet equivalent fire safety standards.

Thermal and Acoustic Insulation Properties

Gypsum sheathing offers superior fire resistance and enhanced thermal insulation compared to plywood sheathing, thanks to its mineral composition that slows heat transfer. Acoustic insulation is also improved with gypsum sheathing, as its dense, non-combustible layers better absorb and dampen sound vibrations. Plywood sheathing, while structurally strong, typically provides lower performance in both thermal insulation and soundproofing capabilities.

Installation Methods and Workability

Gypsum sheathing offers easier installation due to its lighter weight and consistent panel size, allowing quicker handling and fastening compared to plywood sheathing, which is heavier and requires more effort to cut and secure. Gypsum panels are designed with smooth surfaces and uniform edges that facilitate seamless drywall integration, while plywood can present variability in thickness and surface texture, complicating alignment and finishing. The moisture resistance of gypsum sheathing improves workability in damp environments, reducing installation delays caused by swelling or warping common with plywood.

Cost Comparison and Economic Considerations

Gypsum sheathing generally offers a lower initial cost compared to plywood sheathing, making it a budget-friendly option for many construction projects. Its moisture resistance reduces the likelihood of water damage, potentially lowering maintenance and repair expenses over time. While plywood provides greater structural strength, gypsum sheathing's cost efficiency and ease of installation contribute to overall economic advantages in suitable applications.

Environmental Impact and Sustainability

Gypsum sheathing offers a lower environmental impact than plywood sheathing due to its composition, which primarily utilizes abundant natural materials like calcium sulfate dihydrate, reducing reliance on timber resources. It provides enhanced fire resistance and moisture management, contributing to longer building lifespans and decreased waste generation in construction. Plywood, derived from hardwood trees, involves more intensive logging practices and higher energy consumption during production, resulting in a larger carbon footprint compared to gypsum-based products.

Best Use Cases: When to Choose Gypsum or Plywood Sheathing

Gypsum sheathing excels in fire resistance and moisture protection, making it ideal for exterior walls in climates prone to humidity and where enhanced fire safety is required. Plywood sheathing offers superior structural strength and flexibility, preferred for roof decking and shear walls in areas with high wind or seismic activity. Choose gypsum for improved fire ratings and moisture barriers, and plywood for load-bearing applications and structural durability.

Gypsum sheathing vs Plywood sheathing Infographic

materialdif.com

materialdif.com