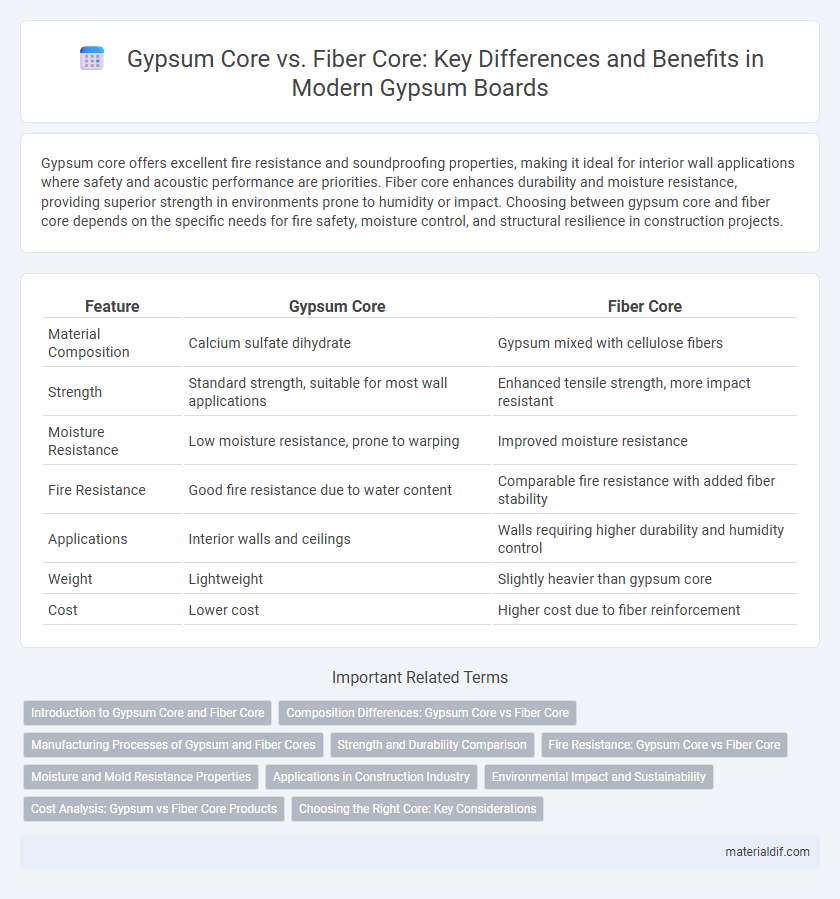

Gypsum core offers excellent fire resistance and soundproofing properties, making it ideal for interior wall applications where safety and acoustic performance are priorities. Fiber core enhances durability and moisture resistance, providing superior strength in environments prone to humidity or impact. Choosing between gypsum core and fiber core depends on the specific needs for fire safety, moisture control, and structural resilience in construction projects.

Table of Comparison

| Feature | Gypsum Core | Fiber Core |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate | Gypsum mixed with cellulose fibers |

| Strength | Standard strength, suitable for most wall applications | Enhanced tensile strength, more impact resistant |

| Moisture Resistance | Low moisture resistance, prone to warping | Improved moisture resistance |

| Fire Resistance | Good fire resistance due to water content | Comparable fire resistance with added fiber stability |

| Applications | Interior walls and ceilings | Walls requiring higher durability and humidity control |

| Weight | Lightweight | Slightly heavier than gypsum core |

| Cost | Lower cost | Higher cost due to fiber reinforcement |

Introduction to Gypsum Core and Fiber Core

Gypsum core is a traditional building material consisting of a dense, calcined gypsum core sandwiched between paper facings, valued for its fire resistance, sound insulation, and affordability. Fiber core gypsum board incorporates reinforcing fibers within the gypsum core, enhancing durability, impact resistance, and moisture tolerance. This innovation improves overall structural performance while maintaining the essential fire-resistant properties of conventional gypsum.

Composition Differences: Gypsum Core vs Fiber Core

Gypsum core primarily consists of calcium sulfate dihydrate, providing a smooth, fire-resistant base commonly used in drywall. Fiber core integrates cellulose fibers with gypsum, enhancing durability, impact resistance, and moisture absorption. The addition of fibers in fiber core significantly improves structural integrity compared to the pure gypsum core.

Manufacturing Processes of Gypsum and Fiber Cores

Gypsum cores are produced primarily through a wet process where calcined gypsum is mixed with water to create a slurry, which is then spread and dried to form rigid panels. Fiber cores incorporate similar methods but include reinforcement fibers such as cellulose or glass fibers within the slurry to enhance strength and durability. Manufacturing fiber cores involves specialized mixing and curing techniques to uniformly distribute fibers and ensure improved resistance to impact and moisture compared to traditional gypsum cores.

Strength and Durability Comparison

Gypsum core panels offer moderate strength and durability suitable for standard interior applications, while fiber core gypsum boards enhance resistance to impact and moisture, providing superior structural integrity. Fiber core technology integrates reinforcing fibers within the gypsum matrix, improving tensile strength and reducing susceptibility to cracking under stress. This makes fiber core panels ideal for high-traffic or humid environments where enhanced durability and longevity are critical.

Fire Resistance: Gypsum Core vs Fiber Core

Gypsum core drywall offers superior fire resistance due to its chemically bound water content, which releases steam when heated, slowing fire spread and improving safety. Fiber core drywall contains reinforcing fibers that provide enhanced impact resistance but generally exhibits lower fire resistance compared to gypsum core panels. Building codes often specify gypsum core materials in fire-rated assemblies to meet stringent fire protection standards.

Moisture and Mold Resistance Properties

Gypsum core boards offer standard moisture resistance but are more susceptible to mold growth when exposed to prolonged damp conditions due to their porous nature. Fiber core gypsum boards incorporate fiberglass strands that enhance structural integrity and significantly improve resistance to moisture penetration and mold development. Choosing fiber core gypsum is ideal for environments prone to high humidity or water exposure, ensuring longer durability and healthier indoor air quality.

Applications in Construction Industry

Gypsum core boards are widely used for interior walls and ceilings due to their fire resistance and smooth finish, making them ideal for residential and commercial buildings. Fiber core gypsum boards incorporate cellulose fibers to enhance impact resistance and moisture durability, which suits high-traffic areas and humid environments such as bathrooms and kitchens. The choice between gypsum core and fiber core depends on specific construction requirements, balancing cost-efficiency with performance characteristics like strength and moisture resistance.

Environmental Impact and Sustainability

Gypsum fiber core panels offer enhanced environmental benefits compared to traditional gypsum core, incorporating recycled natural cellulose fibers that improve sustainability by reducing raw material consumption and promoting recyclability. The production of fiber core panels typically generates lower carbon emissions and decreases waste, supporting sustainable building practices and contributing to LEED certification goals. Both cores are recyclable, but fiber core gypsum's integration of renewable materials results in a reduced environmental footprint throughout its lifecycle.

Cost Analysis: Gypsum vs Fiber Core Products

Gypsum core panels generally offer a lower initial cost compared to fiber core products, making them a cost-effective choice for budget-conscious projects. Fiber core boards, while more expensive upfront, provide enhanced moisture resistance and durability, potentially reducing long-term maintenance expenses. Evaluating total lifecycle costs reveals that gypsum core excels in affordable material and installation costs, whereas fiber core justifies its premium price through superior performance in humid or high-impact environments.

Choosing the Right Core: Key Considerations

Choosing the right core for gypsum boards involves evaluating factors such as fire resistance, moisture tolerance, and structural strength. Gypsum cores offer excellent fire resistance and sound insulation, making them ideal for interior walls and ceilings, while fiber cores enhance durability and moisture resistance, suited for areas with higher humidity or exterior applications. Assessing the specific environmental conditions and performance requirements ensures optimal selection between gypsum and fiber cores for construction projects.

Gypsum Core vs Fiber Core Infographic

materialdif.com

materialdif.com