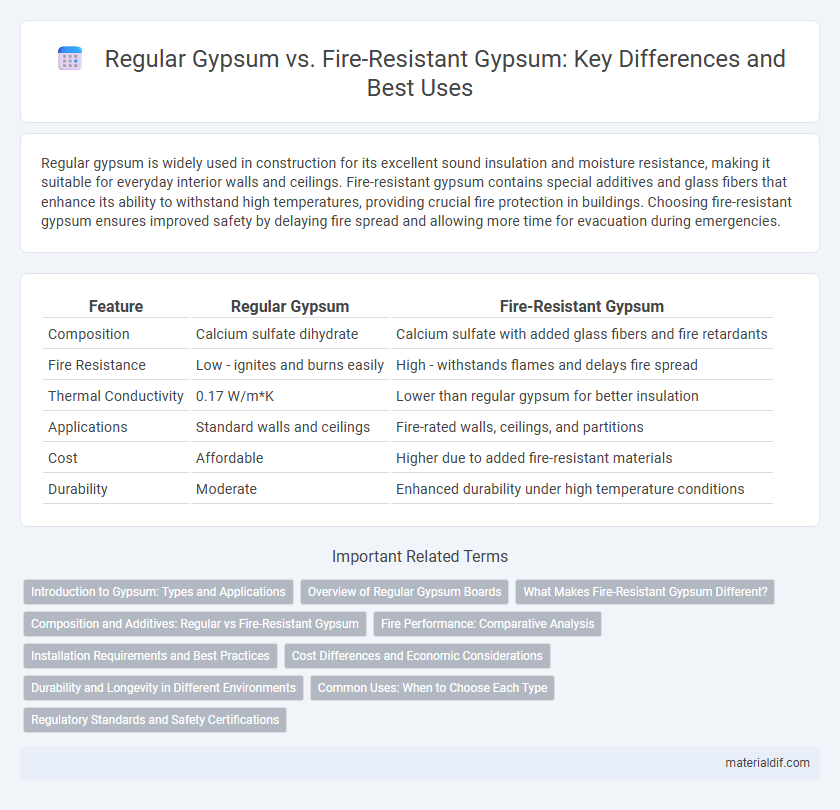

Regular gypsum is widely used in construction for its excellent sound insulation and moisture resistance, making it suitable for everyday interior walls and ceilings. Fire-resistant gypsum contains special additives and glass fibers that enhance its ability to withstand high temperatures, providing crucial fire protection in buildings. Choosing fire-resistant gypsum ensures improved safety by delaying fire spread and allowing more time for evacuation during emergencies.

Table of Comparison

| Feature | Regular Gypsum | Fire-Resistant Gypsum |

|---|---|---|

| Composition | Calcium sulfate dihydrate | Calcium sulfate with added glass fibers and fire retardants |

| Fire Resistance | Low - ignites and burns easily | High - withstands flames and delays fire spread |

| Thermal Conductivity | 0.17 W/m*K | Lower than regular gypsum for better insulation |

| Applications | Standard walls and ceilings | Fire-rated walls, ceilings, and partitions |

| Cost | Affordable | Higher due to added fire-resistant materials |

| Durability | Moderate | Enhanced durability under high temperature conditions |

Introduction to Gypsum: Types and Applications

Regular gypsum, primarily composed of calcium sulfate dihydrate, is widely used in construction for wallboards, plaster, and ceiling tiles due to its ease of installation and smooth finish. Fire-resistant gypsum incorporates glass fibers or other additives to enhance its ability to withstand high temperatures, making it essential for fire-rated wall assemblies and safety-critical areas. Both types serve distinct applications, with regular gypsum favored for general interior surfaces and fire-resistant gypsum mandated in commercial buildings and structures requiring enhanced fire protection.

Overview of Regular Gypsum Boards

Regular gypsum boards consist primarily of a gypsum core sandwiched between two layers of heavy paper, offering standard fire resistance and sound insulation suitable for most interior walls and ceilings. Their cost-effectiveness and ease of installation make them a common choice in residential and commercial construction where enhanced fire resistance is not a critical requirement. Compared to fire-resistant gypsum boards, regular gypsum lacks additional additives or layers that improve fire performance, limiting its use in areas with stringent fire safety regulations.

What Makes Fire-Resistant Gypsum Different?

Fire-resistant gypsum contains non-combustible fibers and additives such as fiberglass, enhancing its ability to withstand high temperatures compared to regular gypsum. Its denser core and specialized additives improve thermal insulation and fire retardant properties, making it a preferred material in fire-rated wall assemblies. The inclusion of chemically bound water within its structure releases steam when heated, slowing down heat transfer and increasing fire resistance.

Composition and Additives: Regular vs Fire-Resistant Gypsum

Regular gypsum primarily consists of calcium sulfate dihydrate, providing basic structural support and moisture resistance. Fire-resistant gypsum incorporates additives such as glass fibers, vermiculite, or other non-combustible materials that enhance its thermal stability and delay heat transfer during fire exposure. These additives increase the gypsum board's fire rating, making it suitable for applications requiring stringent fire safety standards.

Fire Performance: Comparative Analysis

Fire-resistant gypsum contains glass fibers and special additives that enhance its ability to withstand high temperatures, providing superior fire performance compared to regular gypsum. Regular gypsum offers basic fire resistance due to its inherent water content, but it tends to lose structural integrity faster under intense heat. Fire-resistant gypsum is commonly used in building applications requiring strict fire codes, offering extended protection and preventing rapid flame spread.

Installation Requirements and Best Practices

Regular gypsum boards require standard installation techniques involving screws or nails set in a staggered pattern with joints taped and finished for a smooth surface. Fire-resistant gypsum, often thicker and with glass fibers or other additives, demands precise fastening with corrosion-resistant screws and may require multiple layers to meet fire code ratings. Proper sealing of joints and penetrations is critical to maintain fire resistance and comply with building regulations.

Cost Differences and Economic Considerations

Regular gypsum panels generally cost less than fire-resistant gypsum, with prices varying by manufacturer but typically offering savings of 20-40%. Fire-resistant gypsum includes special additives like glass fibers and chemical retardants, which raise production expenses and result in higher market prices. Economic considerations favor regular gypsum for budget-conscious projects without strict fire codes, while fire-resistant gypsum is justified in settings requiring enhanced safety and compliance with fire regulations.

Durability and Longevity in Different Environments

Regular gypsum offers standard durability suitable for dry indoor environments but can degrade quickly when exposed to moisture or heat. Fire-resistant gypsum contains glass fibers and additives that enhance its structural integrity, providing superior longevity in high-temperature and humid conditions. This specialized formulation ensures fire-resistant gypsum maintains stability and strength longer than regular gypsum in demanding environments.

Common Uses: When to Choose Each Type

Regular gypsum is commonly used for interior walls and ceilings in residential and commercial buildings where fire resistance is not a primary concern, offering smooth finishes and ease of installation. Fire-resistant gypsum contains glass fibers and special additives that enhance its ability to withstand high temperatures, making it ideal for areas requiring compliance with fire safety codes such as corridors, stairwells, and commercial kitchens. Choosing fire-resistant gypsum is essential for improving building safety and meeting regulatory standards in fire-rated assemblies, while regular gypsum is suitable for standard construction needs with no stringent fire protection requirements.

Regulatory Standards and Safety Certifications

Regular gypsum typically meets basic building codes such as ASTM C1396 for gypsum board, while fire-resistant gypsum complies with stricter standards like ASTM E119 and UL 263, ensuring enhanced fire resistance. Fire-resistant gypsum boards are certified by organizations such as Underwriters Laboratories (UL) and carry Class A fire ratings, offering superior protection in fire-prone environments. Compliance with these regulatory standards is crucial for construction projects requiring certified fire safety measures, especially in commercial and institutional buildings.

Regular gypsum vs Fire-resistant gypsum Infographic

materialdif.com

materialdif.com