Gypsum insulation offers superior fire resistance and moisture regulation compared to mineral wool, making it ideal for enhancing indoor air quality and safety. Mineral wool insulation excels in thermal and soundproofing properties but is more susceptible to water absorption and potential mold growth. Selecting between gypsum and mineral wool insulation depends on prioritizing either moisture control and fire safety or thermal efficiency and acoustic performance.

Table of Comparison

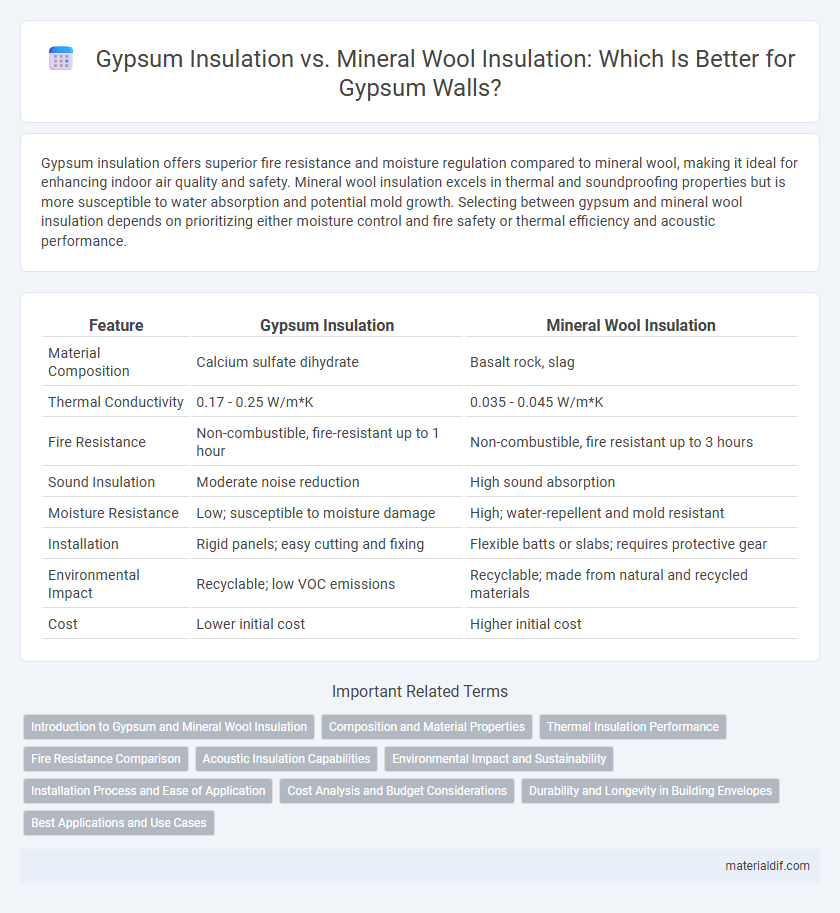

| Feature | Gypsum Insulation | Mineral Wool Insulation |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate | Basalt rock, slag |

| Thermal Conductivity | 0.17 - 0.25 W/m*K | 0.035 - 0.045 W/m*K |

| Fire Resistance | Non-combustible, fire-resistant up to 1 hour | Non-combustible, fire resistant up to 3 hours |

| Sound Insulation | Moderate noise reduction | High sound absorption |

| Moisture Resistance | Low; susceptible to moisture damage | High; water-repellent and mold resistant |

| Installation | Rigid panels; easy cutting and fixing | Flexible batts or slabs; requires protective gear |

| Environmental Impact | Recyclable; low VOC emissions | Recyclable; made from natural and recycled materials |

| Cost | Lower initial cost | Higher initial cost |

Introduction to Gypsum and Mineral Wool Insulation

Gypsum insulation consists of hydrated calcium sulfate used primarily for fire resistance and thermal regulation in buildings, offering excellent moisture absorption properties. Mineral wool insulation, made from spun mineral fibers such as basalt or slag, provides superior soundproofing and higher thermal resistance with enhanced fireproofing capabilities. Both materials contribute to energy efficiency but vary in composition, insulation value, and application suited for different construction needs.

Composition and Material Properties

Gypsum insulation primarily consists of calcium sulfate dihydrate, offering fire resistance and soundproofing with a rigid, non-combustible structure. Mineral wool insulation, made from spun natural or recycled stone and slag fibers, provides superior thermal resistance and excellent sound absorption due to its fibrous, porous composition. The denser, crystalline structure of gypsum contrasts with the fibrous, flexible nature of mineral wool, influencing their respective performance in moisture resistance and thermal conductivity.

Thermal Insulation Performance

Gypsum insulation offers moderate thermal resistance with an R-value typically ranging from 0.45 to 0.5 per inch, effectively reducing heat transfer in residential and commercial buildings. Mineral wool insulation provides superior thermal performance, often achieving R-values between 3.0 and 3.3 per inch, enhancing energy efficiency and maintaining stable indoor temperatures. The higher density and fibrous structure of mineral wool contribute to its better thermal insulation properties compared to gypsum-based materials.

Fire Resistance Comparison

Gypsum insulation offers superior fire resistance due to its high moisture content, which absorbs heat and slows combustion, making it an effective barrier in fire-prone environments. Mineral wool insulation also provides excellent fire resistance, withstanding temperatures up to 1,200degC (2,192degF) without melting, but may lack the inherent moisture-based thermal delay found in gypsum. Both materials are non-combustible, but gypsum's fire-resistant properties are enhanced by its water release during exposure to heat, contributing to prolonged structural integrity during fires.

Acoustic Insulation Capabilities

Gypsum insulation offers moderate acoustic insulation with its density and mass helping to absorb sound vibrations, making it suitable for reducing airborne noise in interior walls. Mineral wool insulation excels in acoustic performance due to its fibrous structure, providing superior sound absorption and effective dampening of both airborne and impact noise. When prioritizing soundproofing, mineral wool insulation generally outperforms gypsum by delivering higher Noise Reduction Coefficient (NRC) ratings and enhanced sound transmission class (STC) values.

Environmental Impact and Sustainability

Gypsum insulation offers a sustainable solution by utilizing abundant natural minerals and exhibiting low embodied energy during production, which reduces its overall carbon footprint compared to mineral wool. Mineral wool insulation, often made from recycled slag or basalt rock, provides durable thermal performance but involves higher energy consumption and emissions during manufacturing. Both materials contribute to environmental efficiency, yet gypsum's recyclability and lower environmental impact make it a preferable choice for eco-conscious construction projects.

Installation Process and Ease of Application

Gypsum insulation offers a straightforward installation process due to its lightweight and ease of cutting, allowing for quick fitting around electrical boxes and irregular shapes, reducing labor time. In contrast, mineral wool insulation, while highly effective for thermal and acoustic performance, requires protective gear during installation because of its fibrous composition, potentially slowing down the application process. The ease of application of gypsum insulation often results in cost savings and less worker fatigue compared to mineral wool, making it ideal for projects with tight schedules or limited skilled labor.

Cost Analysis and Budget Considerations

Gypsum insulation generally offers a lower initial cost compared to mineral wool insulation, making it a budget-friendly choice for many construction projects. Mineral wool insulation, while more expensive upfront, provides superior thermal and acoustic performance, potentially reducing long-term energy expenses. Evaluating the total cost of ownership, including installation, maintenance, and energy savings, is crucial for accurate budget planning between gypsum and mineral wool insulation options.

Durability and Longevity in Building Envelopes

Gypsum insulation offers excellent fire resistance and moisture regulation, contributing to durability in building envelopes, but it can be susceptible to water damage if not properly sealed. Mineral wool insulation provides superior resilience against moisture, mold, and pests, maintaining its thermal properties and structural integrity over time, thus enhancing longevity. The choice between gypsum and mineral wool insulation depends on specific environmental exposures and maintenance considerations for the building envelope.

Best Applications and Use Cases

Gypsum insulation excels in interior wall applications, providing excellent fire resistance and soundproofing for residential and commercial buildings. Mineral wool insulation is ideal for high-temperature environments, offering superior thermal performance and moisture resistance in industrial settings and exterior walls. Gypsum's ease of installation suits retrofit projects, while mineral wool's durability supports harsh climate conditions and acoustic optimization.

Gypsum insulation vs Mineral wool insulation Infographic

materialdif.com

materialdif.com