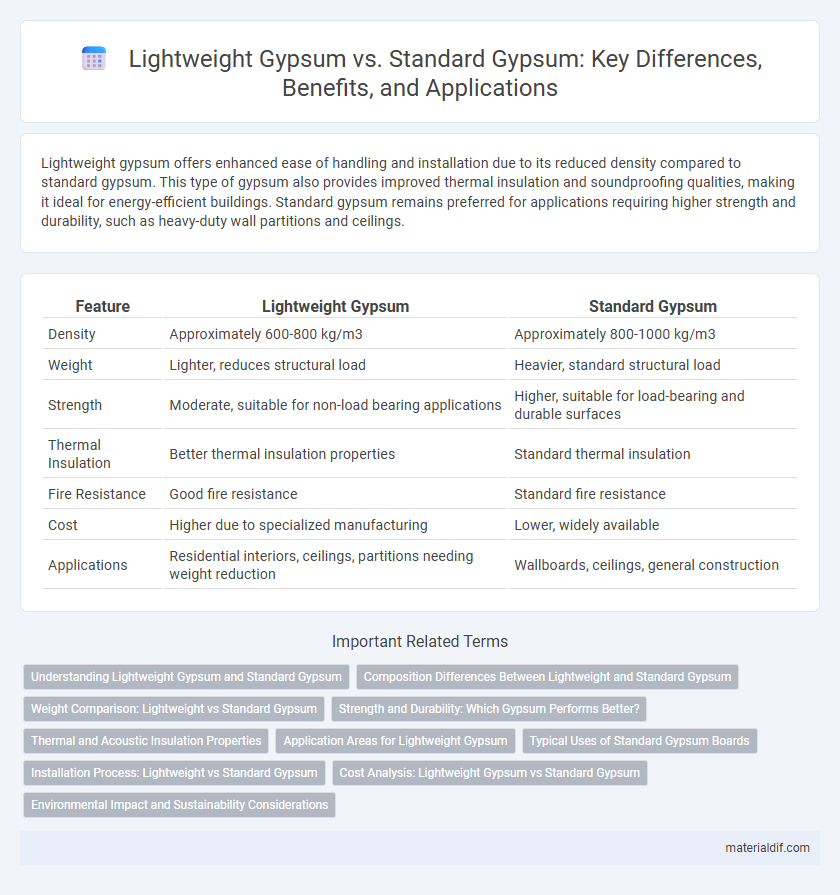

Lightweight gypsum offers enhanced ease of handling and installation due to its reduced density compared to standard gypsum. This type of gypsum also provides improved thermal insulation and soundproofing qualities, making it ideal for energy-efficient buildings. Standard gypsum remains preferred for applications requiring higher strength and durability, such as heavy-duty wall partitions and ceilings.

Table of Comparison

| Feature | Lightweight Gypsum | Standard Gypsum |

|---|---|---|

| Density | Approximately 600-800 kg/m3 | Approximately 800-1000 kg/m3 |

| Weight | Lighter, reduces structural load | Heavier, standard structural load |

| Strength | Moderate, suitable for non-load bearing applications | Higher, suitable for load-bearing and durable surfaces |

| Thermal Insulation | Better thermal insulation properties | Standard thermal insulation |

| Fire Resistance | Good fire resistance | Standard fire resistance |

| Cost | Higher due to specialized manufacturing | Lower, widely available |

| Applications | Residential interiors, ceilings, partitions needing weight reduction | Wallboards, ceilings, general construction |

Understanding Lightweight Gypsum and Standard Gypsum

Lightweight gypsum contains air bubbles or lightweight aggregates, reducing its density to approximately 30-40% less than standard gypsum, making it easier to handle and install. Standard gypsum, with a density typically around 800-1,000 kg/m3, offers higher strength and durability suited for load-bearing applications. Selecting between lightweight and standard gypsum depends on balancing structural requirements with ease of installation and thermal insulation needs.

Composition Differences Between Lightweight and Standard Gypsum

Lightweight gypsum typically contains a higher proportion of air entrainment agents and lightweight fillers such as perlite or vermiculite, reducing its density compared to standard gypsum. Standard gypsum consists mainly of calcium sulfate dihydrate with minimal additives, resulting in a denser and stronger material. The compositional variation directly influences the thermal insulation, sound absorption, and structural properties of the gypsum products.

Weight Comparison: Lightweight vs Standard Gypsum

Lightweight gypsum typically weighs around 8 to 10 pounds per square foot, making it significantly lighter than standard gypsum, which generally weighs about 13 to 15 pounds per square foot. This weight difference improves handling and installation efficiency, reduces structural load, and is preferred in applications requiring weight-sensitive construction materials. Choosing lightweight gypsum can lead to cost savings on labor and supports designs with stringent weight limitations.

Strength and Durability: Which Gypsum Performs Better?

Lightweight gypsum offers improved ease of handling and faster installation but generally exhibits lower compressive strength and less durability compared to standard gypsum. Standard gypsum provides superior strength, making it more suitable for load-bearing applications and environments requiring enhanced impact resistance. When evaluating performance, standard gypsum ensures greater long-term durability and structural integrity in construction projects.

Thermal and Acoustic Insulation Properties

Lightweight gypsum offers superior thermal insulation due to its increased porosity, which traps air and reduces heat transfer compared to standard gypsum. Acoustic insulation is also enhanced in lightweight gypsum, as the material's lower density and cellular structure better absorb sound waves, minimizing noise transmission. Standard gypsum, while more durable and dense, provides less effective thermal and acoustic insulation in building applications.

Application Areas for Lightweight Gypsum

Lightweight gypsum is widely used in interior walls, ceilings, and partitions due to its enhanced thermal insulation and soundproofing properties compared to standard gypsum. It is ideal for high-rise buildings and renovation projects where reducing structural load is critical. Applications often include residential apartments, office spaces, and commercial buildings requiring faster installation and improved energy efficiency.

Typical Uses of Standard Gypsum Boards

Standard gypsum boards are commonly used in residential and commercial interior walls and ceilings due to their durability and fire-resistant properties. They provide excellent sound insulation and are ideal for environments requiring structural strength, such as office buildings and schools. Standard gypsum boards also serve as a reliable surface for painting and wallpapering, making them versatile in various construction applications.

Installation Process: Lightweight vs Standard Gypsum

Lightweight gypsum boards accelerate the installation process due to their reduced weight, enabling easier handling and quicker mounting compared to standard gypsum boards. Standard gypsum requires more labor-intensive support during installation, increasing overall project time and effort. Contractors often prefer lightweight gypsum for large-scale projects to optimize efficiency and reduce fatigue.

Cost Analysis: Lightweight Gypsum vs Standard Gypsum

Lightweight gypsum typically costs 10-20% more than standard gypsum due to its specialized additives and reduced density manufacturing process. Standard gypsum remains more budget-friendly for large-scale projects, offering a lower initial material cost and widespread availability. However, lightweight gypsum can reduce installation labor and transportation expenses, potentially offsetting the higher material price in total project costs.

Environmental Impact and Sustainability Considerations

Lightweight gypsum reduces raw material usage and lowers transportation emissions due to its decreased density compared to standard gypsum, resulting in a smaller carbon footprint. Its improved thermal insulation properties contribute to energy efficiency in buildings, enhancing overall sustainability. However, standard gypsum remains highly recyclable and often contains a higher percentage of recycled content, which supports circular economy practices in construction.

Lightweight gypsum vs Standard gypsum Infographic

materialdif.com

materialdif.com