Gypsum-based adhesives offer faster setting times and superior workability compared to cement-based adhesives, making them ideal for indoor applications requiring precision and smooth finishes. Cement-based adhesives provide greater durability and water resistance, suitable for exterior or high-moisture environments where long-term strength is essential. Choosing between gypsum-based and cement-based adhesives depends on the specific project requirements, including setting time, environmental exposure, and desired finish quality.

Table of Comparison

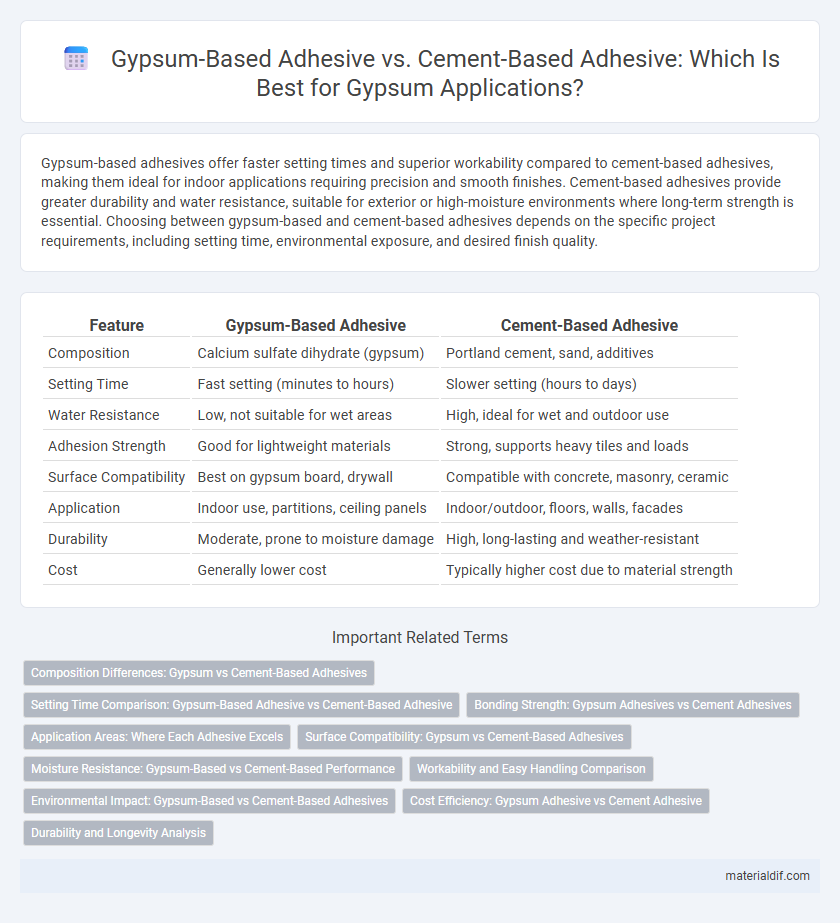

| Feature | Gypsum-Based Adhesive | Cement-Based Adhesive |

|---|---|---|

| Composition | Calcium sulfate dihydrate (gypsum) | Portland cement, sand, additives |

| Setting Time | Fast setting (minutes to hours) | Slower setting (hours to days) |

| Water Resistance | Low, not suitable for wet areas | High, ideal for wet and outdoor use |

| Adhesion Strength | Good for lightweight materials | Strong, supports heavy tiles and loads |

| Surface Compatibility | Best on gypsum board, drywall | Compatible with concrete, masonry, ceramic |

| Application | Indoor use, partitions, ceiling panels | Indoor/outdoor, floors, walls, facades |

| Durability | Moderate, prone to moisture damage | High, long-lasting and weather-resistant |

| Cost | Generally lower cost | Typically higher cost due to material strength |

Composition Differences: Gypsum vs Cement-Based Adhesives

Gypsum-based adhesives primarily consist of calcium sulfate hemihydrate, which reacts with water to form a stable, quick-setting matrix ideal for interior applications due to its fire-resistant properties and smooth finish. Cement-based adhesives contain Portland cement combined with calcium silicates, providing superior strength, durability, and moisture resistance suitable for exterior and heavy-duty uses. The chemical composition difference influences setting time, bonding strength, and environmental resistance, making gypsum adhesives preferred for delicate gypsum board installations, while cement adhesives excel in robust masonry and tile bonding.

Setting Time Comparison: Gypsum-Based Adhesive vs Cement-Based Adhesive

Gypsum-based adhesives typically set faster than cement-based adhesives, with initial setting times ranging from 10 to 30 minutes, making them ideal for quick repairs and installations. Cement-based adhesives generally require longer curing periods, often between 24 to 48 hours, due to their hydration process, which provides stronger long-term bonding. The faster setting time of gypsum adhesives enhances productivity in construction projects where time constraints are critical, whereas cement adhesives offer superior durability for structural applications.

Bonding Strength: Gypsum Adhesives vs Cement Adhesives

Gypsum-based adhesives offer superior bonding strength on gypsum board surfaces due to their compatibility with the substrate, ensuring enhanced adhesion and reduced risk of delamination. Cement-based adhesives provide robust bonding for porous and concrete substrates but may lack optimal adhesion on gypsum materials, leading to potential weak points. Selecting a gypsum adhesive maximizes the durability and bond integrity for gypsum applications, outperforming cement adhesives in this specific context.

Application Areas: Where Each Adhesive Excels

Gypsum-based adhesives excel in interior applications such as drywall installation, plastering, and decorative molding due to their fast setting time and smooth finish. Cement-based adhesives are preferred for exterior or high-moisture environments like tiling on floors, walls, and swimming pools because of their superior water resistance and durability. Choosing between the two depends largely on the specific project requirements, with gypsum-based adhesives optimizing indoor, dry conditions and cement-based adhesives enhancing strength in wet or load-bearing applications.

Surface Compatibility: Gypsum vs Cement-Based Adhesives

Gypsum-based adhesives are highly compatible with porous and delicate surfaces such as drywall, gypsum boards, and certain plaster finishes, ensuring strong adhesion without surface damage. Cement-based adhesives excel on rough, non-porous surfaces like concrete, masonry, and brick, offering superior durability and moisture resistance. Choosing between gypsum and cement adhesives depends on the substrate's porosity, texture, and structural requirements for optimal bonding performance.

Moisture Resistance: Gypsum-Based vs Cement-Based Performance

Gypsum-based adhesives exhibit lower moisture resistance compared to cement-based adhesives, as gypsum tends to absorb water and lose adhesion strength in wet conditions. Cement-based adhesives provide superior durability and resistance to moisture, making them ideal for wet or high-humidity environments. The chemical composition of cement enhances its water-resistant properties, ensuring longer-lasting performance in damp applications.

Workability and Easy Handling Comparison

Gypsum-based adhesive offers superior workability due to its smooth consistency and faster setting time, allowing for easier spreading and quicker project completion. Cement-based adhesive is heavier and requires more mixing effort, resulting in a denser texture that can be harder to handle and apply uniformly. The ease of handling gypsum-based adhesives makes them preferable for intricate tile installations and interior wall applications.

Environmental Impact: Gypsum-Based vs Cement-Based Adhesives

Gypsum-based adhesives have a lower environmental impact compared to cement-based adhesives due to their reduced carbon dioxide emissions during production and higher recyclability. Cement-based adhesives generate significant CO2, contributing to climate change and resource depletion, whereas gypsum products use abundant natural minerals and consume less energy. The biodegradability and non-toxic composition of gypsum adhesives further enhance their sustainability profile in construction applications.

Cost Efficiency: Gypsum Adhesive vs Cement Adhesive

Gypsum-based adhesives typically offer greater cost efficiency compared to cement-based adhesives due to lower raw material and manufacturing costs, resulting in reduced overall project expenses. The faster setting time of gypsum adhesives further minimizes labor costs and construction delays, enhancing economic benefits. Cement-based adhesives, while durable, often incur higher costs from longer curing periods and increased material usage, making gypsum adhesives a more budget-friendly choice for many applications.

Durability and Longevity Analysis

Gypsum-based adhesives offer faster setting times and better moisture regulation, but tend to have lower durability compared to cement-based adhesives, especially in high-stress or wet environments. Cement-based adhesives provide superior longevity due to their enhanced resistance to cracking, water exposure, and mechanical wear, making them ideal for structural and exterior applications. The chemical composition of cement-based adhesives ensures stronger bonding and long-term performance, whereas gypsum adhesives are more suitable for temporary or interior use where durability demands are lower.

Gypsum-based adhesive vs Cement-based adhesive Infographic

materialdif.com

materialdif.com