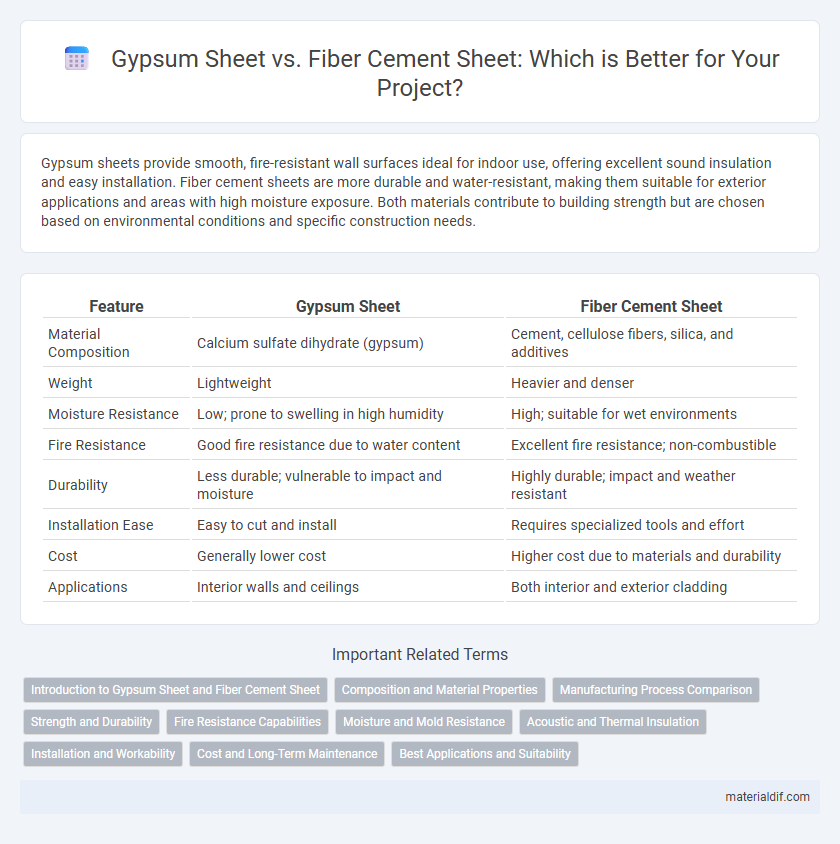

Gypsum sheets provide smooth, fire-resistant wall surfaces ideal for indoor use, offering excellent sound insulation and easy installation. Fiber cement sheets are more durable and water-resistant, making them suitable for exterior applications and areas with high moisture exposure. Both materials contribute to building strength but are chosen based on environmental conditions and specific construction needs.

Table of Comparison

| Feature | Gypsum Sheet | Fiber Cement Sheet |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate (gypsum) | Cement, cellulose fibers, silica, and additives |

| Weight | Lightweight | Heavier and denser |

| Moisture Resistance | Low; prone to swelling in high humidity | High; suitable for wet environments |

| Fire Resistance | Good fire resistance due to water content | Excellent fire resistance; non-combustible |

| Durability | Less durable; vulnerable to impact and moisture | Highly durable; impact and weather resistant |

| Installation Ease | Easy to cut and install | Requires specialized tools and effort |

| Cost | Generally lower cost | Higher cost due to materials and durability |

| Applications | Interior walls and ceilings | Both interior and exterior cladding |

Introduction to Gypsum Sheet and Fiber Cement Sheet

Gypsum sheets are lightweight, fire-resistant panels made from calcium sulfate dihydrate that provide smooth surfaces for interior wall applications, known for their ease of installation and cost-effectiveness. Fiber cement sheets combine cement, cellulose fibers, and sand to create durable, moisture-resistant panels ideal for both interior and exterior use with enhanced structural strength. Both materials serve as common alternatives for wall cladding, with gypsum sheets excelling in indoor environments and fiber cement sheets preferred for exposure to harsh weather conditions.

Composition and Material Properties

Gypsum sheets are primarily composed of calcium sulfate dihydrate mixed with paper facings, offering excellent fire resistance and sound insulation due to their mineral-based core. Fiber cement sheets combine cement, cellulose fibers, and sand, resulting in a denser material with superior moisture resistance and structural durability ideal for exterior applications. The inorganic nature of fiber cement sheets also makes them less prone to mold and warping compared to the more porous gypsum sheets.

Manufacturing Process Comparison

Gypsum sheets are manufactured by mixing calcium sulfate dihydrate with water, forming a slurry that is then sandwiched between paper layers and dried. Fiber cement sheets combine cement, cellulose fibers, and silica, which are molded and cured under high pressure and temperature to enhance durability. The gypsum sheet process is faster and more energy-efficient, while fiber cement sheets require longer curing times and offer greater resistance to moisture and fire.

Strength and Durability

Gypsum sheets offer moderate strength and are prone to moisture damage, limiting their durability in wet environments, while fiber cement sheets provide superior strength, impact resistance, and excellent durability against water, mold, and fire. Fiber cement sheets maintain structural integrity under harsh conditions, making them ideal for external applications and high-humidity areas. The enhanced fiber reinforcement in fiber cement sheets significantly outperforms gypsum sheets in load-bearing capacity and lifespan.

Fire Resistance Capabilities

Gypsum sheets offer superior fire resistance due to their high water content, which slows heat transfer and provides effective fireproofing in building applications. Fiber cement sheets, while durable and moisture-resistant, generally have lower fire resistance compared to gypsum sheets because they lack the inherent fire-retardant properties of gypsum. Choosing gypsum sheets enhances fire safety in walls and ceilings, making them preferable for fire-rated construction assemblies.

Moisture and Mold Resistance

Gypsum sheets have limited moisture resistance and are prone to mold growth in high-humidity environments, making them less suitable for wet areas. Fiber cement sheets exhibit superior moisture and mold resistance due to their dense, non-porous composition, providing enhanced durability in bathrooms, kitchens, and exterior applications. This makes fiber cement sheets a preferred choice in construction projects requiring long-term exposure to moisture and mold-prone conditions.

Acoustic and Thermal Insulation

Gypsum sheets offer superior acoustic insulation due to their dense composition, effectively reducing sound transmission in residential and commercial spaces. Fiber cement sheets provide enhanced thermal insulation, resisting heat transfer and contributing to energy efficiency in building envelopes. Both materials serve distinct insulation purposes, with gypsum excelling in soundproofing and fiber cement optimizing thermal performance.

Installation and Workability

Gypsum sheets offer faster installation due to their lightweight nature and ease of cutting with standard tools, making them ideal for interior applications. Fiber cement sheets require specialized tools and more time during installation because of their density and toughness, but they provide superior durability and moisture resistance. Workability of gypsum sheets is enhanced by their smooth surface which facilitates finishing, whereas fiber cement sheets demand careful handling to avoid chipping and dust generation.

Cost and Long-Term Maintenance

Gypsum sheets generally offer a lower initial cost compared to fiber cement sheets, making them a budget-friendly option for interior wall applications. However, fiber cement sheets exhibit superior durability and resistance to moisture, reducing long-term maintenance expenses, especially in humid or exterior environments. Investing in fiber cement sheets can lead to significant savings over time due to fewer repairs and replacements.

Best Applications and Suitability

Gypsum sheets excel in interior applications such as wall partitions and ceilings due to their excellent fire resistance, sound insulation, and smooth finish, making them ideal for residential and commercial spaces. Fiber cement sheets offer superior durability and moisture resistance, making them suitable for exterior cladding, wet areas like bathrooms and kitchens, and environments exposed to harsh weather or termites. Choosing between gypsum and fiber cement depends on the specific requirements of fire resistance, moisture exposure, and structural durability in the intended application.

Gypsum sheet vs Fiber cement sheet Infographic

materialdif.com

materialdif.com