Natural gypsum is mined directly from geological deposits, containing impurities that can affect its purity and performance in construction applications. Synthetic gypsum is a byproduct of industrial processes like flue gas desulfurization, offering a more consistent chemical composition and reduced environmental impact. Choosing between natural and synthetic gypsum depends on factors such as availability, cost, and specific project requirements for strength and durability.

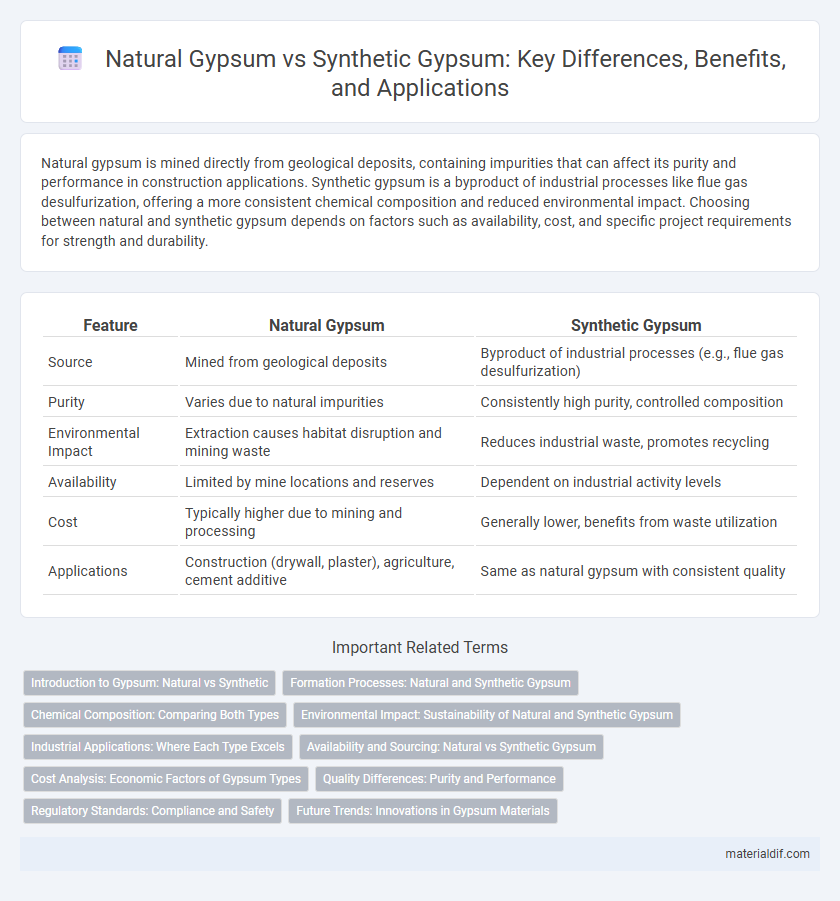

Table of Comparison

| Feature | Natural Gypsum | Synthetic Gypsum |

|---|---|---|

| Source | Mined from geological deposits | Byproduct of industrial processes (e.g., flue gas desulfurization) |

| Purity | Varies due to natural impurities | Consistently high purity, controlled composition |

| Environmental Impact | Extraction causes habitat disruption and mining waste | Reduces industrial waste, promotes recycling |

| Availability | Limited by mine locations and reserves | Dependent on industrial activity levels |

| Cost | Typically higher due to mining and processing | Generally lower, benefits from waste utilization |

| Applications | Construction (drywall, plaster), agriculture, cement additive | Same as natural gypsum with consistent quality |

Introduction to Gypsum: Natural vs Synthetic

Natural gypsum is a mineral composed of calcium sulfate dihydrate, commonly extracted from sedimentary rock deposits, while synthetic gypsum is a byproduct of industrial processes such as flue gas desulfurization in power plants. Natural gypsum contains impurities and requires mining and processing, whereas synthetic gypsum offers higher purity and consistent quality, making it a sustainable alternative in construction and agriculture. Both forms serve as key raw materials in cement production, soil conditioning, and plaster manufacturing.

Formation Processes: Natural and Synthetic Gypsum

Natural gypsum forms through the evaporation of mineral-rich waters in sedimentary basins, resulting in calcium sulfate dihydrate deposits over geological timescales. Synthetic gypsum is produced as a byproduct of industrial processes such as flue gas desulfurization in coal-fired power plants, where sulfur dioxide is chemically converted into calcium sulfate. The distinct formation processes lead to variations in purity and particle size, influencing their respective applications in construction and agriculture.

Chemical Composition: Comparing Both Types

Natural gypsum primarily consists of calcium sulfate dihydrate (CaSO4*2H2O) with minor impurities such as silica, clay, and organic matter, which can affect its purity and setting time in construction applications. Synthetic gypsum, often produced as a byproduct of flue gas desulfurization in power plants, features a highly consistent chemical composition with higher purity levels of calcium sulfate dihydrate and significantly fewer impurities. This uniformity in synthetic gypsum enhances its performance in industrial uses like drywall production by improving strength, smoothness, and setting behavior compared to natural gypsum.

Environmental Impact: Sustainability of Natural and Synthetic Gypsum

Natural gypsum mining disrupts ecosystems and depletes mineral reserves, contributing to habitat loss and increased carbon emissions. Synthetic gypsum, a byproduct of industrial processes like flue gas desulfurization, reduces waste and lowers the need for quarrying, promoting a circular economy. Utilizing synthetic gypsum enhances sustainability by minimizing environmental degradation and conserving natural resources in construction and manufacturing.

Industrial Applications: Where Each Type Excels

Natural gypsum, mined directly from geological deposits, excels in construction applications such as drywall manufacturing and cement production due to its purity and consistent mineral composition. Synthetic gypsum, a byproduct of industrial processes like flue gas desulfurization in power plants, offers superior environmental benefits and is widely used in sustainable building materials and soil conditioning. Both types serve critical roles in agriculture and environmental technologies, with natural gypsum improving soil structure and synthetic gypsum aiding sulfur capture and waste recycling.

Availability and Sourcing: Natural vs Synthetic Gypsum

Natural gypsum is mined from geological deposits, with availability dependent on regional mining operations and environmental regulations, often limited by local reserves. Synthetic gypsum is a byproduct of industrial processes such as flue gas desulfurization in power plants, offering a consistent and renewable supply tied to coal combustion and other industrial emissions. Sourcing synthetic gypsum reduces reliance on natural deposits and promotes waste recycling, enhancing supply stability in industries like construction and agriculture.

Cost Analysis: Economic Factors of Gypsum Types

Natural gypsum typically incurs lower extraction and processing costs due to its abundant availability and simpler mining procedures, making it more economically favorable for large-scale construction projects. Synthetic gypsum, produced as a byproduct of industrial processes such as flue gas desulfurization, often involves higher production costs but benefits from reduced raw material expenses and environmental compliance incentives. Evaluating cost-effectiveness requires analyzing regional supply chains, transportation expenses, and demand fluctuations, as synthetic gypsum can provide price stability amid natural gypsum shortages.

Quality Differences: Purity and Performance

Natural gypsum typically contains impurities such as clay, sand, and organic matter, which can affect its purity and consistency in construction applications. Synthetic gypsum, produced from flue gas desulfurization processes, offers higher purity levels with fewer contaminants, resulting in superior performance and strength in cement and drywall manufacturing. The enhanced consistency of synthetic gypsum contributes to improved workability and durability in finished products compared to natural gypsum varieties.

Regulatory Standards: Compliance and Safety

Natural gypsum and synthetic gypsum both adhere to stringent regulatory standards ensuring environmental compliance and occupational safety, with agencies like the EPA and OSHA setting specific guidelines for handling and disposal. Synthetic gypsum, often derived from flue gas desulfurization, typically undergoes rigorous testing to meet purity and contaminant limits, reducing hazardous waste concerns compared to natural gypsum mining. Compliance with these standards ensures that both forms are safe for use in construction and agriculture, minimizing health risks and environmental impact.

Future Trends: Innovations in Gypsum Materials

Future trends in gypsum materials emphasize sustainable innovations, with synthetic gypsum gaining prominence for its reduced environmental impact compared to natural gypsum. Advances in processing technologies enhance the purity and consistency of synthetic gypsum, making it a preferred choice for construction and environmental applications. Research continues to explore novel composite blends and recycling methods to optimize the lifecycle and performance of both natural and synthetic gypsum products.

Natural gypsum vs Synthetic gypsum Infographic

materialdif.com

materialdif.com