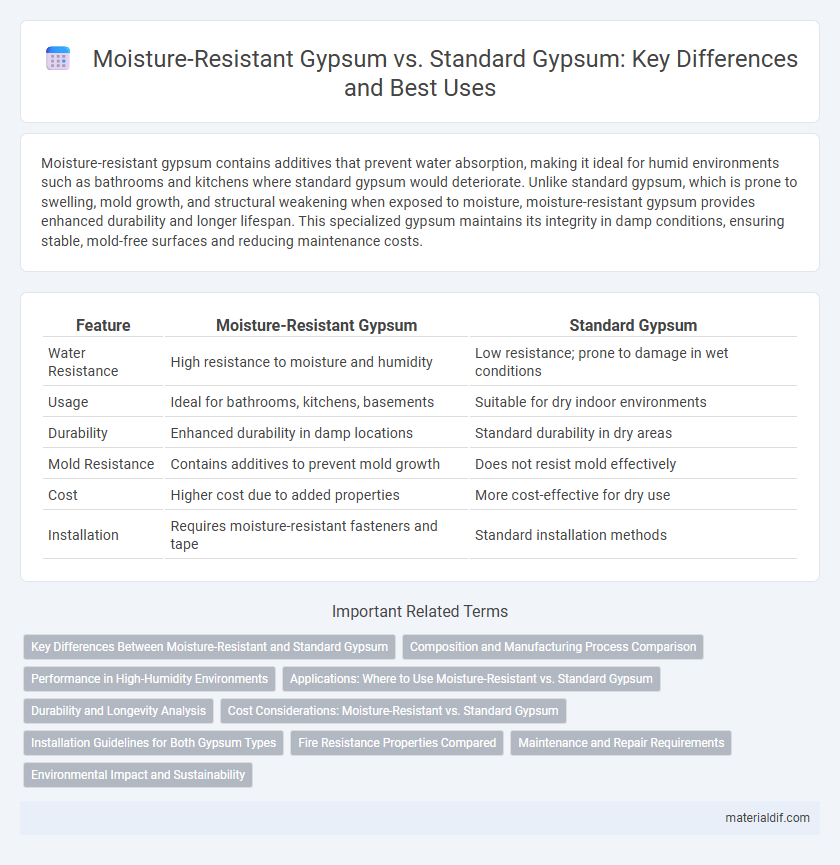

Moisture-resistant gypsum contains additives that prevent water absorption, making it ideal for humid environments such as bathrooms and kitchens where standard gypsum would deteriorate. Unlike standard gypsum, which is prone to swelling, mold growth, and structural weakening when exposed to moisture, moisture-resistant gypsum provides enhanced durability and longer lifespan. This specialized gypsum maintains its integrity in damp conditions, ensuring stable, mold-free surfaces and reducing maintenance costs.

Table of Comparison

| Feature | Moisture-Resistant Gypsum | Standard Gypsum |

|---|---|---|

| Water Resistance | High resistance to moisture and humidity | Low resistance; prone to damage in wet conditions |

| Usage | Ideal for bathrooms, kitchens, basements | Suitable for dry indoor environments |

| Durability | Enhanced durability in damp locations | Standard durability in dry areas |

| Mold Resistance | Contains additives to prevent mold growth | Does not resist mold effectively |

| Cost | Higher cost due to added properties | More cost-effective for dry use |

| Installation | Requires moisture-resistant fasteners and tape | Standard installation methods |

Key Differences Between Moisture-Resistant and Standard Gypsum

Moisture-resistant gypsum contains water-repellent additives and a denser core, enabling it to withstand humid environments without degrading, unlike standard gypsum which absorbs moisture and weakens over time. The paper facing on moisture-resistant gypsum is treated to prevent mold growth, whereas standard gypsum is susceptible to mold and mildew in damp conditions. These features make moisture-resistant gypsum ideal for bathrooms and kitchens, while standard gypsum is best suited for dry, interior spaces.

Composition and Manufacturing Process Comparison

Moisture-resistant gypsum incorporates water-repellent additives such as silicone compounds or wax emulsions within its core composition, enhancing its ability to withstand high humidity and water exposure compared to standard gypsum, which primarily consists of calcium sulfate dihydrate without these additives. The manufacturing process of moisture-resistant gypsum involves integrating hydrophobic agents during the slurry mixing stage, followed by controlled drying techniques to ensure these agents are evenly distributed and maintain the board's structural integrity under moist conditions. Standard gypsum relies on conventional calcination and hydration processes without moisture barriers, resulting in lower resistance to water and increased susceptibility to mold and degradation in damp environments.

Performance in High-Humidity Environments

Moisture-resistant gypsum outperforms standard gypsum in high-humidity environments due to its enhanced mold and mildew resistance, making it ideal for bathrooms and basements. Its proprietary additives reduce water absorption, maintaining structural integrity and preventing warping or deterioration over time. Standard gypsum lacks these features, leading to quicker degradation when exposed to excessive moisture.

Applications: Where to Use Moisture-Resistant vs. Standard Gypsum

Moisture-resistant gypsum is ideal for high-humidity areas such as bathrooms, kitchens, basements, and laundry rooms, providing enhanced protection against mold and mildew growth. Standard gypsum is best suited for dry, interior spaces like living rooms, bedrooms, and offices where moisture exposure is minimal. Using the appropriate type of gypsum in the correct application ensures durability and maintains structural integrity over time.

Durability and Longevity Analysis

Moisture-resistant gypsum contains water-repellent additives that significantly enhance its durability compared to standard gypsum, which is prone to deterioration in humid environments. The enhanced composition reduces the risk of mold growth, swelling, and structural weakening, thereby extending the service life of drywall installations. In environments with high humidity, moisture-resistant gypsum can last up to 50% longer than standard gypsum, making it a preferred choice for bathrooms, kitchens, and basements.

Cost Considerations: Moisture-Resistant vs. Standard Gypsum

Moisture-resistant gypsum typically costs 20-30% more than standard gypsum due to its enhanced materials and manufacturing process designed to prevent mold and moisture damage. While the initial investment is higher, moisture-resistant gypsum reduces long-term expenses by minimizing repairs and maintenance in humid environments. Standard gypsum remains more cost-effective for dry, low-moisture areas where resistance to water is not a critical factor.

Installation Guidelines for Both Gypsum Types

Moisture-resistant gypsum requires installation in environments with controlled humidity, using vapor barriers and corrosion-resistant fasteners to prevent mold and deterioration. Standard gypsum should be installed in dry areas, fastened securely with appropriate screws, and joints sealed with paper or fiberglass tape and joint compound. Both types demand adherence to manufacturer guidelines for cutouts, corner beads, and finishing to ensure durability and performance.

Fire Resistance Properties Compared

Moisture-resistant gypsum boards contain additives like fiberglass and water-repellent chemicals, enhancing not only their moisture resistance but also their fire resistance by slowing heat transfer and preventing rapid ignition. Standard gypsum, composed primarily of calcium sulfate dihydrate, inherently provides fire resistance due to the water molecules within, which absorb heat and release steam during a fire, but lacks the specialized additives that improve performance in high-moisture areas. Fire ratings for moisture-resistant gypsum typically meet or exceed those of standard gypsum, making them suitable for environments requiring both moisture control and enhanced fire protection.

Maintenance and Repair Requirements

Moisture-resistant gypsum contains additives that enhance durability by preventing mold growth and water damage, significantly reducing maintenance and repair frequency compared to standard gypsum. Standard gypsum absorbs moisture easily, leading to deterioration, frequent repairs, and higher long-term costs. Choosing moisture-resistant gypsum provides a more reliable, low-maintenance wall solution in high-humidity environments.

Environmental Impact and Sustainability

Moisture-resistant gypsum boards contain additives like wax and silicone that enhance durability, reducing the frequency of replacements and lowering overall waste compared to standard gypsum. Standard gypsum, being more susceptible to water damage, often leads to higher resource consumption and landfill accumulation, negatively impacting environmental sustainability. Choosing moisture-resistant gypsum contributes to sustainable construction by minimizing material waste and promoting longer-lasting building interiors.

Moisture-resistant gypsum vs Standard gypsum Infographic

materialdif.com

materialdif.com