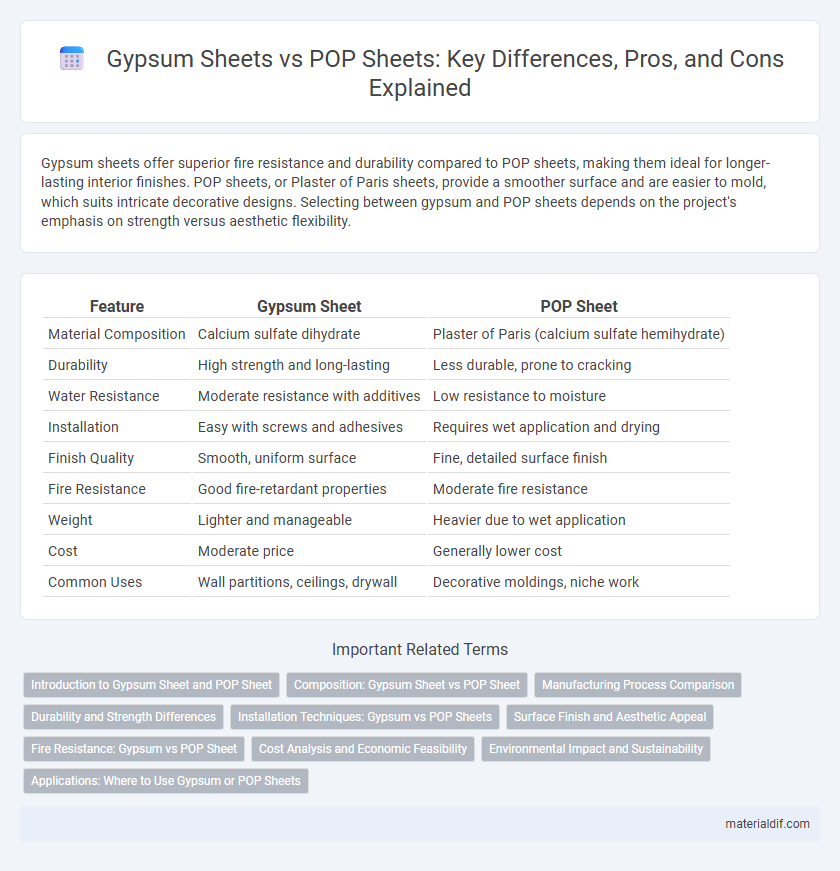

Gypsum sheets offer superior fire resistance and durability compared to POP sheets, making them ideal for longer-lasting interior finishes. POP sheets, or Plaster of Paris sheets, provide a smoother surface and are easier to mold, which suits intricate decorative designs. Selecting between gypsum and POP sheets depends on the project's emphasis on strength versus aesthetic flexibility.

Table of Comparison

| Feature | Gypsum Sheet | POP Sheet |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate | Plaster of Paris (calcium sulfate hemihydrate) |

| Durability | High strength and long-lasting | Less durable, prone to cracking |

| Water Resistance | Moderate resistance with additives | Low resistance to moisture |

| Installation | Easy with screws and adhesives | Requires wet application and drying |

| Finish Quality | Smooth, uniform surface | Fine, detailed surface finish |

| Fire Resistance | Good fire-retardant properties | Moderate fire resistance |

| Weight | Lighter and manageable | Heavier due to wet application |

| Cost | Moderate price | Generally lower cost |

| Common Uses | Wall partitions, ceilings, drywall | Decorative moldings, niche work |

Introduction to Gypsum Sheet and POP Sheet

Gypsum sheets are pre-manufactured boards composed of gypsum plaster sandwiched between layers of paper, offering enhanced durability, moisture resistance, and fireproofing compared to traditional Plaster of Paris (POP) sheets. POP sheets, made from fine Plaster of Paris powder, are typically applied as a wet plaster that sets quickly to form smooth, sculpted surfaces but lack the structural strength and uniform thickness of gypsum sheets. Gypsum sheets provide a faster installation process and superior acoustic insulation, making them ideal for modern interior wall and ceiling applications.

Composition: Gypsum Sheet vs POP Sheet

Gypsum sheets are composed primarily of natural gypsum mineral combined with additives like cellulose fibers and binders to enhance strength and moisture resistance. POP (Plaster of Paris) sheets consist of calcined gypsum, which is gypsum heated to remove water content, resulting in a finer powder that is rehydrated and molded into sheets. The key compositional difference lies in gypsum sheets using natural gypsum in a stabilized form, whereas POP sheets rely on the processed form of gypsum for quick setting and smooth finishing properties.

Manufacturing Process Comparison

Gypsum sheets are manufactured by mixing gypsum plaster with additives, then molding and drying them into rigid panels, ensuring uniform thickness and enhanced moisture resistance. POP (Plaster of Paris) sheets are produced by heating natural gypsum to remove water, grinding it into a fine powder, and then mixing with water to form molds that harden rapidly. The gypsum sheet manufacturing process offers greater consistency and durability, while POP sheets provide quicker setting times but less structural strength.

Durability and Strength Differences

Gypsum sheets offer superior durability compared to POP sheets due to their high density and resistance to moisture, making them ideal for long-lasting wall and ceiling applications. While POP sheets provide a smooth finish, they are more brittle and prone to cracking under stress, limiting their structural strength. The enhanced tensile strength of gypsum sheets ensures better load-bearing capacity and resilience in various construction environments.

Installation Techniques: Gypsum vs POP Sheets

Gypsum sheets offer straightforward installation with lightweight panels that can be easily cut and fixed using screws or nails, reducing labor time and mess compared to POP sheets. POP sheets require wet mixing and manual application, demanding skilled labor to mold and shape the material on-site, leading to longer installation durations. Gypsum sheets provide cleaner, faster installations with minimal drying time, while POP sheets excel in intricate designs but involve more complex, time-consuming techniques.

Surface Finish and Aesthetic Appeal

Gypsum sheets offer a smooth, uniform surface with a fine finish, ideal for modern interiors requiring a sleek and polished look. POP sheets provide a more textured surface, which can add a decorative, traditional appeal but may require additional finishing for a flawless appearance. The choice between gypsum and POP sheets largely depends on the desired aesthetic, with gypsum favored for clean, contemporary designs and POP preferred for ornate detailing.

Fire Resistance: Gypsum vs POP Sheet

Gypsum sheets offer superior fire resistance compared to POP (Plaster of Paris) sheets due to their high water content, which helps absorb heat and slow fire spread. Gypsum contains chemically combined water that releases as steam when exposed to fire, providing a natural barrier, whereas POP sheets lack this inherent fire-retardant property and tend to deteriorate faster under high temperatures. Construction standards often favor gypsum sheets for fire-rated partitions and ceilings because of their proven performance in fire resistance tests.

Cost Analysis and Economic Feasibility

Gypsum sheets generally offer lower overall installation costs compared to POP (Plaster of Paris) sheets due to reduced labor intensity and faster application processes. The durability and moisture resistance of gypsum sheets often result in lower maintenance expenses, enhancing long-term economic feasibility. Although POP sheets may have a lower initial material price, the frequent need for repairs and reapplications can lead to higher cumulative costs over time.

Environmental Impact and Sustainability

Gypsum sheets demonstrate superior environmental sustainability compared to POP (Plaster of Paris) sheets due to their higher recyclability and use of natural gypsum, reducing landfill waste and resource extraction. The manufacturing process of gypsum sheets emits fewer greenhouse gases and consumes less energy than POP sheets, which rely on calcined gypsum that demands higher temperatures. Gypsum sheets also offer better durability and moisture resistance, extending their lifespan and minimizing the frequency of replacements, thereby lowering the overall environmental footprint.

Applications: Where to Use Gypsum or POP Sheets

Gypsum sheets are ideal for ceilings, walls, and partitions in residential and commercial buildings due to their durability, fire resistance, and sound insulation properties. POP sheets, made from Plaster of Paris, are better suited for decorative applications such as false ceilings and intricate moldings because of their smooth finish and ease of sculpting. Choosing between gypsum and POP sheets depends on the need for structural strength versus aesthetic detailing in interior design projects.

Gypsum Sheet vs POP Sheet Infographic

materialdif.com

materialdif.com