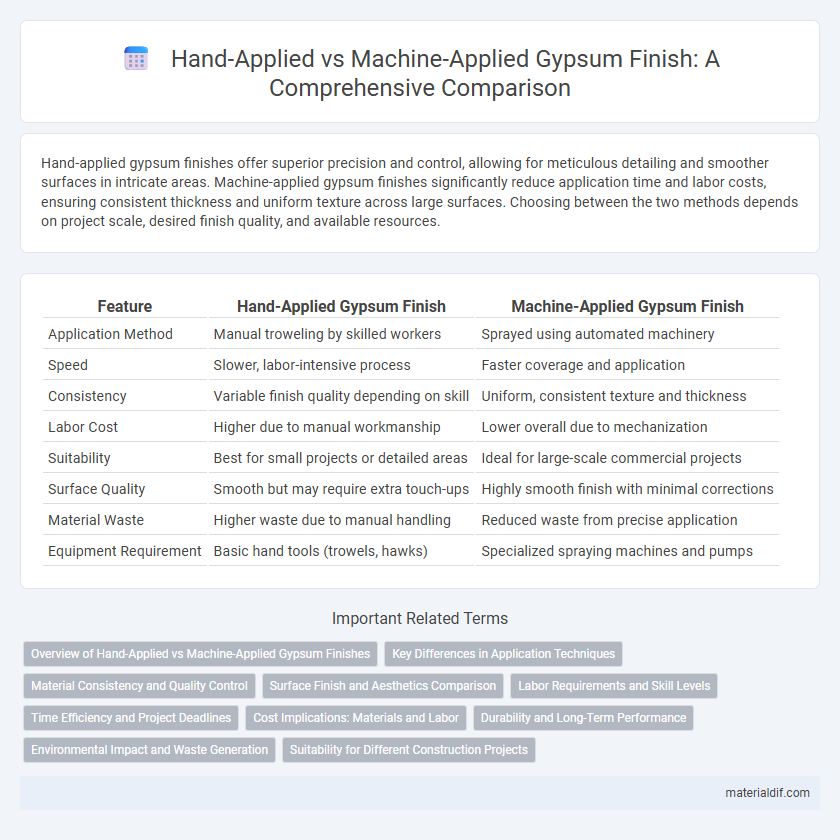

Hand-applied gypsum finishes offer superior precision and control, allowing for meticulous detailing and smoother surfaces in intricate areas. Machine-applied gypsum finishes significantly reduce application time and labor costs, ensuring consistent thickness and uniform texture across large surfaces. Choosing between the two methods depends on project scale, desired finish quality, and available resources.

Table of Comparison

| Feature | Hand-Applied Gypsum Finish | Machine-Applied Gypsum Finish |

|---|---|---|

| Application Method | Manual troweling by skilled workers | Sprayed using automated machinery |

| Speed | Slower, labor-intensive process | Faster coverage and application |

| Consistency | Variable finish quality depending on skill | Uniform, consistent texture and thickness |

| Labor Cost | Higher due to manual workmanship | Lower overall due to mechanization |

| Suitability | Best for small projects or detailed areas | Ideal for large-scale commercial projects |

| Surface Quality | Smooth but may require extra touch-ups | Highly smooth finish with minimal corrections |

| Material Waste | Higher waste due to manual handling | Reduced waste from precise application |

| Equipment Requirement | Basic hand tools (trowels, hawks) | Specialized spraying machines and pumps |

Overview of Hand-Applied vs Machine-Applied Gypsum Finishes

Hand-applied gypsum finishes offer greater control for intricate detailing and customization, making them ideal for small-scale or ornate projects. Machine-applied gypsum finishes provide faster application and uniform coverage, enhancing productivity on large-scale constructions with consistent texture. Selection depends on project size, desired finish quality, and labor skill level.

Key Differences in Application Techniques

Hand-applied gypsum finish involves manual troweling, allowing for meticulous control over texture and detail, which is ideal for intricate surfaces and smaller areas. Machine-applied gypsum finish utilizes spray equipment, enabling faster coverage and uniform thickness over large surfaces, significantly reducing labor time and improving efficiency. The choice between these techniques depends on the project scale, surface complexity, and desired finish quality.

Material Consistency and Quality Control

Hand-applied gypsum finish often results in variable material consistency due to differences in skill and technique, leading to uneven surfaces and potential quality control issues. Machine-applied gypsum finish provides greater uniformity by delivering a consistent mix and precise application thickness, enhancing overall finish quality. Automated processes reduce human error, ensuring better compliance with industry standards and improved durability of the gypsum surface.

Surface Finish and Aesthetics Comparison

Hand-applied gypsum finish offers a smoother, more detailed surface finish, allowing craftsmen to address imperfections and create intricate textures that enhance aesthetic appeal. Machine-applied gypsum finish provides a consistent, uniform surface ideal for large-scale projects but may lack the fine detailing achievable by manual application. Variations in surface finish between hand and machine application significantly impact the final visual quality and texture of gypsum walls and ceilings.

Labor Requirements and Skill Levels

Hand-applied gypsum finishes demand higher labor intensity and advanced craftsmanship, relying on skilled artisans to achieve smooth, precise textures. Machine-applied gypsum finishes reduce labor requirements by automating application, enabling faster coverage with less skill, though often sacrificing fine detailing. Selecting between hand and machine application depends on project scale, budget constraints, and desired finish quality.

Time Efficiency and Project Deadlines

Hand-applied gypsum finishes typically require significantly more labor hours, resulting in slower completion times and potential delays in meeting project deadlines. Machine-applied gypsum finishes enhance time efficiency by enabling faster application speeds and consistent coverage, reducing labor costs and accelerating project timelines. Projects with tight deadlines benefit from machine application due to its ability to streamline processes and maintain high-quality finishes within shorter periods.

Cost Implications: Materials and Labor

Hand-applied gypsum finish typically incurs higher labor costs due to the time-intensive manual application process, requiring skilled craftsmen for consistent quality. Machine-applied gypsum finish reduces labor expenses by accelerating application speed and ensuring uniform thickness, although initial investment in machinery and maintenance can increase upfront costs. Material wastage tends to be lower with machine application, contributing to overall cost efficiency despite the need for specialized equipment.

Durability and Long-Term Performance

Hand-applied gypsum finishes offer a higher level of craftsmanship with better adaptability to complex surfaces, resulting in enhanced durability due to meticulous surface preparation and application control. Machine-applied gypsum finishes deliver consistent thickness and texture, improving long-term performance by minimizing human error but may lack the fine detail achievable by hand application. Both methods require proper curing and sealing to maximize durability and resistance to cracking, moisture, and wear over time.

Environmental Impact and Waste Generation

Hand-applied gypsum finishes typically generate more waste due to uneven application and higher material runoff, increasing environmental burden through greater gypsum disposal. Machine-applied gypsum finishes offer precise control and reduced material waste, minimizing the environmental impact by optimizing gypsum usage and lowering energy consumption during application. Implementing machine application methods supports sustainable construction practices by significantly cutting down waste generation and resource depletion compared to manual techniques.

Suitability for Different Construction Projects

Hand-applied gypsum finish offers superior precision and is ideal for intricate architectural details, restoration projects, and small-scale renovations where craftsmanship is crucial. Machine-applied gypsum finish excels in large commercial constructions and high-volume residential developments, providing faster application rates and consistent surface quality. Project scale, complexity, and desired finish quality dictate the suitability of hand-applied versus machine-applied gypsum finishes.

Hand-applied gypsum finish vs Machine-applied gypsum finish Infographic

materialdif.com

materialdif.com