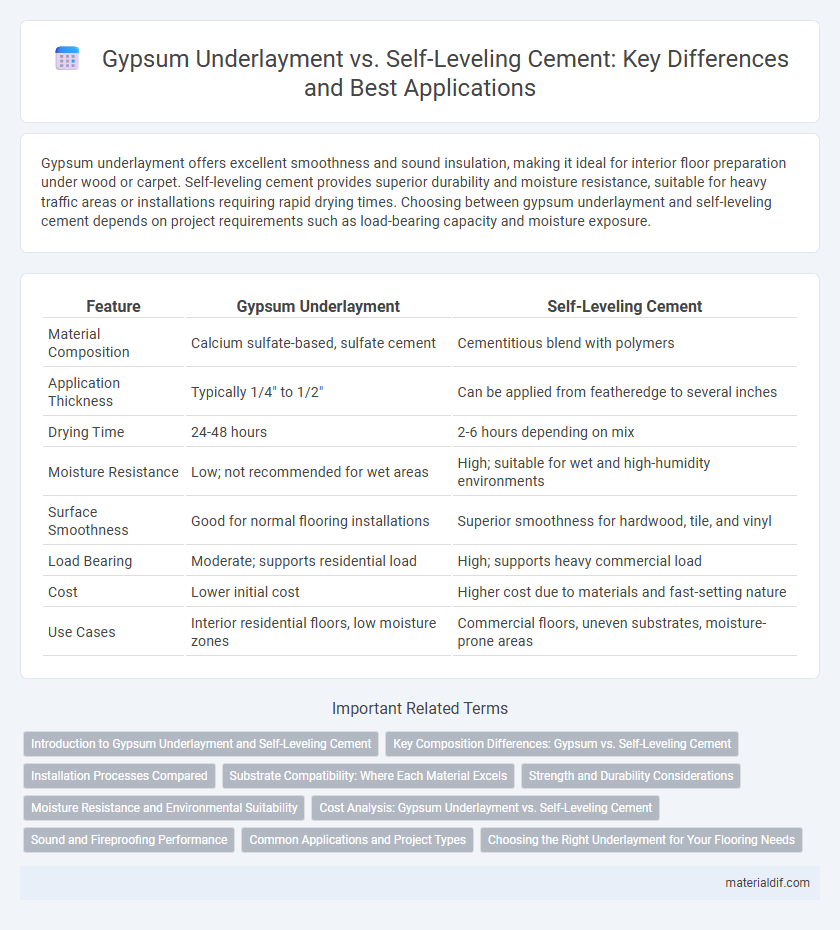

Gypsum underlayment offers excellent smoothness and sound insulation, making it ideal for interior floor preparation under wood or carpet. Self-leveling cement provides superior durability and moisture resistance, suitable for heavy traffic areas or installations requiring rapid drying times. Choosing between gypsum underlayment and self-leveling cement depends on project requirements such as load-bearing capacity and moisture exposure.

Table of Comparison

| Feature | Gypsum Underlayment | Self-Leveling Cement |

|---|---|---|

| Material Composition | Calcium sulfate-based, sulfate cement | Cementitious blend with polymers |

| Application Thickness | Typically 1/4" to 1/2" | Can be applied from featheredge to several inches |

| Drying Time | 24-48 hours | 2-6 hours depending on mix |

| Moisture Resistance | Low; not recommended for wet areas | High; suitable for wet and high-humidity environments |

| Surface Smoothness | Good for normal flooring installations | Superior smoothness for hardwood, tile, and vinyl |

| Load Bearing | Moderate; supports residential load | High; supports heavy commercial load |

| Cost | Lower initial cost | Higher cost due to materials and fast-setting nature |

| Use Cases | Interior residential floors, low moisture zones | Commercial floors, uneven substrates, moisture-prone areas |

Introduction to Gypsum Underlayment and Self-Leveling Cement

Gypsum underlayment is a cementitious material designed to provide a smooth, durable surface for installing floor coverings, known for its lightweight properties and fast drying time. Self-leveling cement is a polymer-modified cementitious compound that flows easily to create an even, level substrate for floors, with superior crack resistance and high compressive strength. Both materials improve floor flatness and moisture resistance but differ in application method and performance characteristics, making selection dependent on project requirements.

Key Composition Differences: Gypsum vs. Self-Leveling Cement

Gypsum underlayment primarily consists of calcium sulfate hemihydrate, which provides a smooth, workable surface ideal for finishing floors, whereas self-leveling cement is composed mainly of cementitious materials combined with polymers and fine aggregates for enhanced strength and rapid curing. Unlike gypsum's softer, more porous matrix, self-leveling cement features a denser, more durable structure that resists moisture and cracking. The chemical and physical differences in these compositions dictate their suitability, with gypsum underlayment favored for lightweight interior applications and self-leveling cement preferred in high-traffic or moisture-prone areas.

Installation Processes Compared

Gypsum underlayment requires careful mixing and spreading with a trowel to ensure an even surface, often needing drying times of 24 to 48 hours for proper curing. Self-leveling cement is poured and spreads out evenly on its own, reducing manual labor and significantly decreasing drying times to as little as a few hours. The faster installation and smoother finish of self-leveling cement make it ideal for projects demanding quick turnaround and minimal surface preparation.

Substrate Compatibility: Where Each Material Excels

Gypsum underlayment excels on wood and concrete substrates, providing excellent adhesion and moisture regulation for interior floors. Self-leveling cement performs best on concrete surfaces, offering superior strength and rapid curing, ideal for heavy traffic areas. Compatibility with substrate porosity and moisture levels dictates optimal product selection to ensure durable, smooth flooring installations.

Strength and Durability Considerations

Gypsum underlayment offers moderate strength suitable for light to medium traffic areas but may be prone to surface damage and moisture sensitivity. Self-leveling cement provides superior compressive strength and enhanced durability, making it ideal for high-traffic or industrial environments. The cement's resistance to cracking and wear ensures a longer lifespan compared to gypsum-based products.

Moisture Resistance and Environmental Suitability

Gypsum underlayment offers moderate moisture resistance suitable for dry interior environments but tends to deteriorate when exposed to high humidity or water. Self-leveling cement provides superior moisture resistance and durability, making it ideal for areas prone to moisture, such as bathrooms and basements. Environmentally, gypsum is a natural, recyclable material with low VOC emissions, while self-leveling cement typically contains higher levels of cementitious components and additives, impacting its environmental footprint.

Cost Analysis: Gypsum Underlayment vs. Self-Leveling Cement

Gypsum underlayment typically costs between $2 to $4 per square foot, making it a more budget-friendly choice for interior flooring projects compared to self-leveling cement, which ranges from $3 to $7 per square foot due to higher material and labor expenses. Installation of gypsum underlayment is faster and requires less specialized labor, further reducing overall project costs. Self-leveling cement provides superior durability and moisture resistance but may necessitate additional substrate preparation, increasing upfront investment.

Sound and Fireproofing Performance

Gypsum underlayment offers superior fire resistance due to its non-combustible properties and ability to slow heat transfer, making it an excellent choice for fireproofing applications. Self-leveling cement provides moderate soundproofing by creating a dense, solid layer that reduces impact noise but lacks the insulating air pockets found in gypsum underlayments. For projects prioritizing enhanced fire protection and sound attenuation, gypsum underlayment outperforms self-leveling cement in both categories.

Common Applications and Project Types

Gypsum underlayment is commonly used in residential and commercial flooring projects for smoothing subfloors before installing tile, carpet, or hardwood, providing excellent moisture resistance and sound insulation. Self-leveling cement is preferred in industrial and large-scale commercial applications requiring rapid leveling of uneven surfaces, particularly in high-traffic areas needing high durability and fast curing times. Both materials serve as effective substrates, with gypsum underlayment favored for lighter loads and aesthetic finishes, while self-leveling cement handles heavy-duty demands and complex structural requirements.

Choosing the Right Underlayment for Your Flooring Needs

Gypsum underlayment offers excellent moisture resistance and soundproofing, making it ideal for residential and commercial flooring projects that require durability and comfort. Self-leveling cement provides superior leveling properties and faster curing times, perfect for uneven substrates and heavy foot traffic areas. Selecting the right underlayment depends on your specific flooring type, subfloor condition, and project timeline, ensuring optimal performance and longevity.

Gypsum underlayment vs Self-leveling cement Infographic

materialdif.com

materialdif.com