Gypsum-based joint compounds offer superior ease of application and faster drying times compared to cement-based joint compounds, making them ideal for interior drywall finishing. Cement-based compounds provide greater resistance to moisture and are better suited for exterior or high-humidity environments where durability is critical. Choosing between the two depends largely on the specific project requirements, balancing workability against environmental resilience.

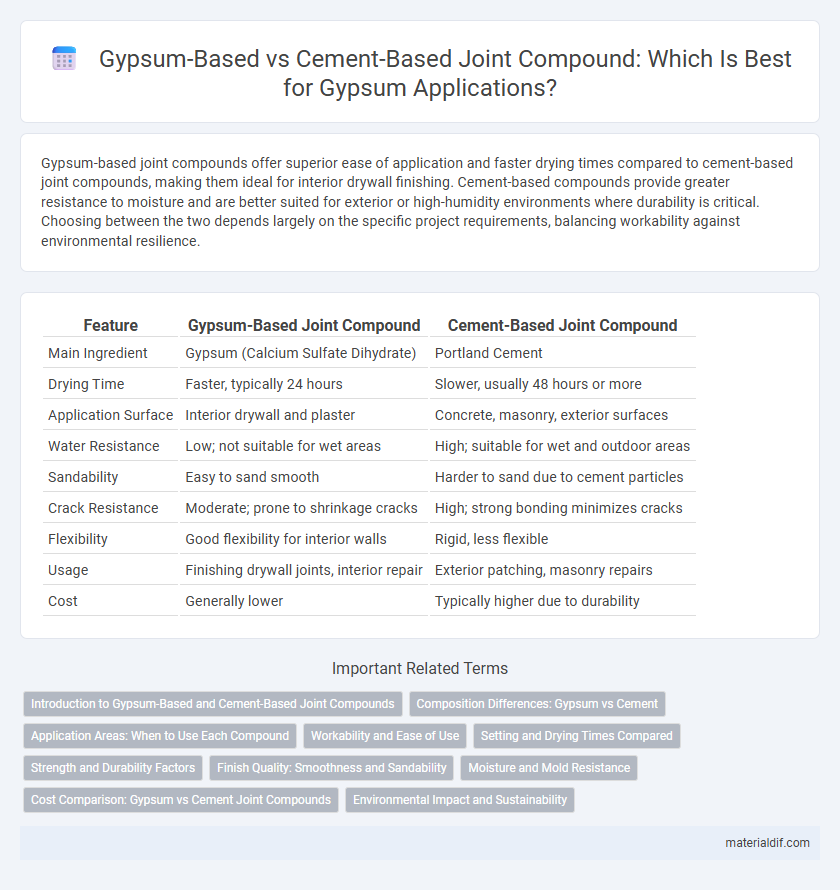

Table of Comparison

| Feature | Gypsum-Based Joint Compound | Cement-Based Joint Compound |

|---|---|---|

| Main Ingredient | Gypsum (Calcium Sulfate Dihydrate) | Portland Cement |

| Drying Time | Faster, typically 24 hours | Slower, usually 48 hours or more |

| Application Surface | Interior drywall and plaster | Concrete, masonry, exterior surfaces |

| Water Resistance | Low; not suitable for wet areas | High; suitable for wet and outdoor areas |

| Sandability | Easy to sand smooth | Harder to sand due to cement particles |

| Crack Resistance | Moderate; prone to shrinkage cracks | High; strong bonding minimizes cracks |

| Flexibility | Good flexibility for interior walls | Rigid, less flexible |

| Usage | Finishing drywall joints, interior repair | Exterior patching, masonry repairs |

| Cost | Generally lower | Typically higher due to durability |

Introduction to Gypsum-Based and Cement-Based Joint Compounds

Gypsum-based joint compounds are primarily composed of calcium sulfate dihydrate, offering ease of application, quick drying times, and superior sandability, making them ideal for interior wall finishing and drywall taping. Cement-based joint compounds, containing Portland cement as the main binder, provide enhanced moisture resistance and durability, suitable for exterior applications or areas exposed to higher humidity. Understanding the composition and performance characteristics of these compounds helps in selecting the right material for specific construction and renovation tasks.

Composition Differences: Gypsum vs Cement

Gypsum-based joint compounds primarily consist of calcium sulfate dihydrate, which provides quick-setting and easy sanding properties, making them ideal for interior drywall applications. Cement-based joint compounds contain Portland cement, characterized by a mixture of calcium silicates and aluminates that offer superior durability and moisture resistance, suited for exterior or high-moisture environments. The fundamental composition difference influences drying time, workability, and suitability for various construction needs.

Application Areas: When to Use Each Compound

Gypsum-based joint compound is ideal for interior walls and ceilings due to its smooth finish, fast drying time, and ease of sanding, making it perfect for drywall taping, embedding joint tape, and final coat applications. Cement-based joint compound offers superior moisture resistance and durability, making it suitable for exterior repairs, cement boards, and areas exposed to water or high humidity such as bathrooms and basements. Use gypsum-based compounds primarily for indoor, low-moisture environments, while cement-based compounds are preferred for outdoor or moisture-prone applications requiring enhanced strength and water resistance.

Workability and Ease of Use

Gypsum-based joint compound offers superior workability due to its smooth texture and longer open time, allowing easier application and sanding for seamless finishes. Cement-based joint compounds tend to set faster and develop higher initial strength but can be more difficult to manipulate and require more effort during application and finishing. The ease of use with gypsum formulations makes them preferred for interior drywall work, while cement-based compounds are more suited for exterior or high-moisture environments requiring durability.

Setting and Drying Times Compared

Gypsum-based joint compounds typically set and dry faster, often within 24 to 48 hours, making them ideal for quicker project completion. Cement-based joint compounds require longer drying times, sometimes up to 72 hours or more, due to slower hydration reactions and higher moisture retention. The faster setting time of gypsum-based compounds enhances efficiency in drywall finishing, while cement-based products provide superior durability in exterior or moisture-prone environments.

Strength and Durability Factors

Gypsum-based joint compound offers superior workability but generally lacks the compressive strength and durability of cement-based joint compound, which provides enhanced resistance to cracking and moisture exposure. Cement-based compounds are ideal for exterior or high-moisture environments due to their ability to withstand weathering and structural stress over time. The denser composition of cement-based joint compounds contributes to longer-lasting repair work and greater overall strength in heavy-duty applications.

Finish Quality: Smoothness and Sandability

Gypsum-based joint compound offers superior smoothness and ease of sanding compared to cement-based joint compound, resulting in a finer finish ideal for detailed interior wall work. Its lightweight, creamy consistency allows for seamless application and minimizes surface imperfections, enhancing paint adhesion and overall aesthetic appeal. Cement-based joint compounds tend to be coarser and harder to sand, making them less suitable for achieving a polished finish on drywall surfaces.

Moisture and Mold Resistance

Gypsum-based joint compounds offer moderate moisture resistance but are more susceptible to mold growth when exposed to prolonged damp conditions. Cement-based joint compounds provide superior moisture and mold resistance due to their alkaline nature, which inhibits microbial growth. For environments with high humidity or frequent water exposure, cement-based compounds are preferred for their durability and enhanced protection against mold development.

Cost Comparison: Gypsum vs Cement Joint Compounds

Gypsum-based joint compounds generally cost less than cement-based joint compounds due to lower raw material and manufacturing expenses. Cement-based compounds often require additives and longer curing times, which increase overall project costs. The initial investment in gypsum joint compounds makes them more economical for large-scale drywall finishing and interior wall applications.

Environmental Impact and Sustainability

Gypsum-based joint compounds typically exhibit lower environmental impact due to their natural mineral composition and lower embodied energy compared to cement-based alternatives, which generate higher CO2 emissions during cement production. Gypsum's recyclability and non-toxic properties contribute to sustainability by minimizing landfill waste and reducing indoor air pollution. Cement-based joint compounds, while offering durability, often involve intensive mining and energy consumption, presenting greater challenges for eco-friendly construction.

Gypsum-based joint compound vs Cement-based joint compound Infographic

materialdif.com

materialdif.com