Gypsum stucco offers a smoother finish and faster drying time compared to lime stucco, making it ideal for interior applications where quick turnaround is essential. Lime stucco provides superior breathability and durability, which enhances moisture regulation and longevity, especially in exterior environments. Choosing between gypsum and lime stucco depends on the specific project requirements, including environmental exposure and desired aesthetic qualities.

Table of Comparison

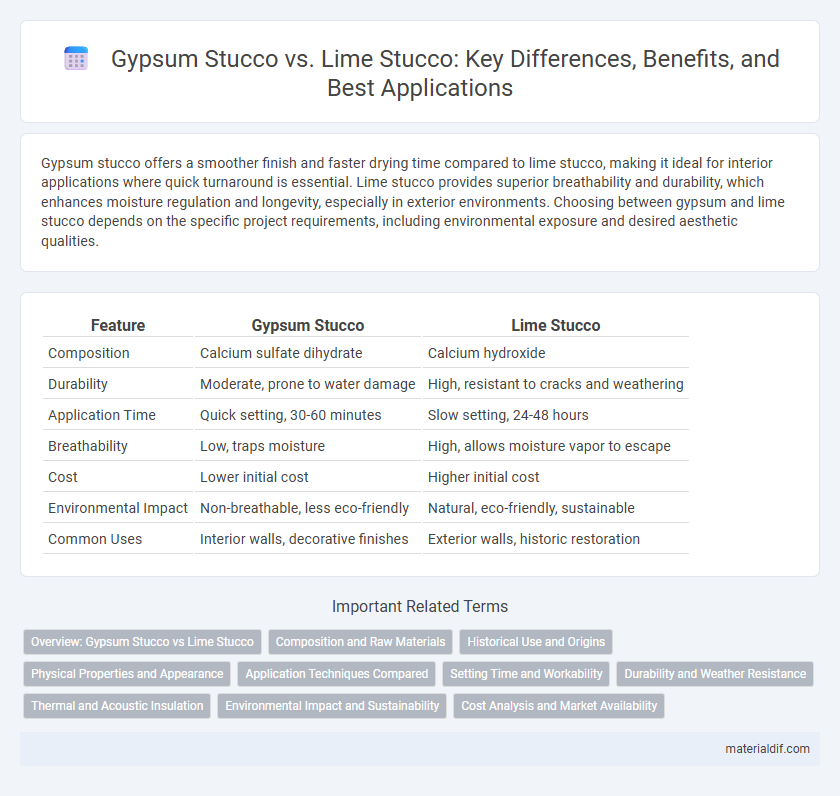

| Feature | Gypsum Stucco | Lime Stucco |

|---|---|---|

| Composition | Calcium sulfate dihydrate | Calcium hydroxide |

| Durability | Moderate, prone to water damage | High, resistant to cracks and weathering |

| Application Time | Quick setting, 30-60 minutes | Slow setting, 24-48 hours |

| Breathability | Low, traps moisture | High, allows moisture vapor to escape |

| Cost | Lower initial cost | Higher initial cost |

| Environmental Impact | Non-breathable, less eco-friendly | Natural, eco-friendly, sustainable |

| Common Uses | Interior walls, decorative finishes | Exterior walls, historic restoration |

Overview: Gypsum Stucco vs Lime Stucco

Gypsum stucco is a gypsum-based plaster known for its ease of application, fast drying time, and smooth finish, commonly used in interior walls for its fire resistance and mold-resistant properties. Lime stucco, made from lime, sand, and water, offers superior breathability, flexibility, and durability, making it ideal for exterior surfaces and historic restoration projects. While gypsum stucco provides quick installation and cost efficiency, lime stucco excels in moisture regulation and long-term weather resistance.

Composition and Raw Materials

Gypsum stucco primarily consists of calcium sulfate dihydrate derived from natural gypsum deposits or synthetic byproducts, offering faster setting times and smoother finishes. Lime stucco is composed mainly of calcium hydroxide obtained by calcining limestone, combined with aggregates like sand for durability and breathability. The differences in raw materials influence their chemical properties, with gypsum providing rigidity and lime delivering flexibility and moisture resistance.

Historical Use and Origins

Gypsum stucco originated in ancient Egypt and Rome, prized for its fast-setting properties and smooth finish, making it ideal for decorative plasterwork. Lime stucco dates back to Ancient Greece and Rome, valued for its breathability and durability in various climates, often used in historic Mediterranean architecture. Both materials have distinct historical significance, with gypsum preferred for rapid indoor applications and lime favored for exterior longevity and moisture regulation.

Physical Properties and Appearance

Gypsum stucco offers a smooth, fine texture with quick drying times and less shrinkage due to its crystalline structure, making it ideal for interior applications where a clean, polished finish is desired. Lime stucco features a coarser texture with greater flexibility and breathability, allowing it to accommodate thermal expansion and moisture vapor transmission, which enhances durability in exterior environments. The color of gypsum stucco tends to be brighter and whiter, whereas lime stucco usually has a muted, earthy tone that develops a natural patina over time.

Application Techniques Compared

Gypsum stucco is applied using wet coats that dry quickly, allowing for faster project completion and smoother finishes, making it ideal for interior walls. Lime stucco requires a longer curing time and multiple layers, promoting better breathability and durability, often preferred for historic restoration or exterior surfaces. Application techniques for lime stucco involve mixing with water and sand to create a pliable plaster that can be troweled on in thick coats, whereas gypsum stucco relies on pre-mixed formulations for faster application and reduced drying time.

Setting Time and Workability

Gypsum stucco sets rapidly, often within 30 minutes to an hour, enabling faster project completion but requiring quick application and finishing. Lime stucco has a significantly slower setting time, ranging from several hours to days, which improves workability and allows for more intricate detailing and smoother finishes. The extended curing period of lime stucco also enhances durability and breathability, making it ideal for traditional and restoration projects where moisture regulation is crucial.

Durability and Weather Resistance

Gypsum stucco offers smooth finishes but is less durable and more susceptible to moisture damage compared to lime stucco, which boasts superior weather resistance and longevity. Lime stucco's natural permeability allows it to withstand harsh weather conditions by preventing trapped moisture and reducing cracking. This makes lime stucco a preferred choice for exterior applications requiring enhanced durability and resistance to environmental factors.

Thermal and Acoustic Insulation

Gypsum stucco offers moderate thermal insulation with an R-value typically around 0.5 per inch, making it suitable for interior applications where temperature regulation is less critical. Lime stucco provides better breathability and superior acoustic insulation due to its denser composition, effectively reducing sound transmission in both residential and commercial buildings. While gypsum excels in fire resistance and ease of installation, lime stucco's natural thermal mass contributes to improved energy efficiency by stabilizing indoor temperatures.

Environmental Impact and Sustainability

Gypsum stucco has a lower carbon footprint due to its abundant natural mineral source and energy-efficient production process compared to lime stucco, which requires high-temperature kilns producing significant CO2 emissions. Gypsum stucco also offers superior recyclability and inertness, reducing landfill waste and environmental toxicity, whereas lime stucco undergoes chemical reactions that can release CO2 during carbonation. The use of gypsum stucco supports sustainable building practices by minimizing resource extraction impacts and enhancing indoor air quality through less alkaline content.

Cost Analysis and Market Availability

Gypsum stucco typically costs less than lime stucco due to lower material and labor expenses, making it a more economical choice for many construction projects. Market availability of gypsum stucco is higher, with widespread distribution and faster manufacturing turnaround compared to lime stucco, which has limited suppliers and longer production times. Cost efficiency and accessibility often drive the preference for gypsum stucco in both residential and commercial applications.

Gypsum stucco vs Lime stucco Infographic

materialdif.com

materialdif.com