Gypsum wallboard offers superior fire resistance and easier installation compared to cement wallboard, making it ideal for interior walls and ceilings. Cement wallboard provides greater moisture resistance and durability, suitable for exterior applications and wet areas such as bathrooms and kitchens. Choosing between the two depends on the specific requirements for moisture control, fire safety, and structural strength in the construction project.

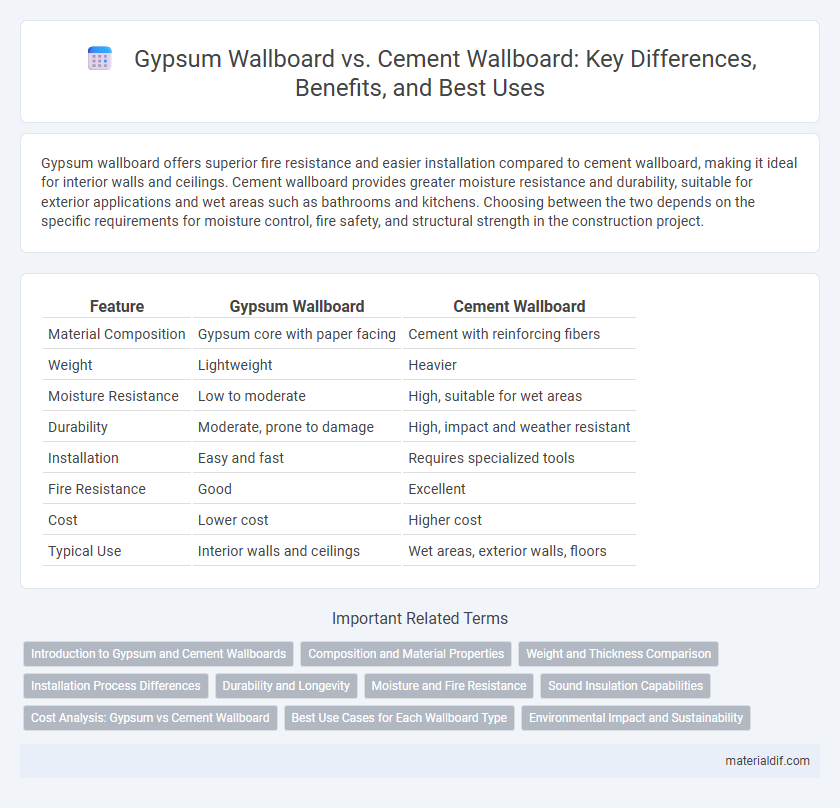

Table of Comparison

| Feature | Gypsum Wallboard | Cement Wallboard |

|---|---|---|

| Material Composition | Gypsum core with paper facing | Cement with reinforcing fibers |

| Weight | Lightweight | Heavier |

| Moisture Resistance | Low to moderate | High, suitable for wet areas |

| Durability | Moderate, prone to damage | High, impact and weather resistant |

| Installation | Easy and fast | Requires specialized tools |

| Fire Resistance | Good | Excellent |

| Cost | Lower cost | Higher cost |

| Typical Use | Interior walls and ceilings | Wet areas, exterior walls, floors |

Introduction to Gypsum and Cement Wallboards

Gypsum wallboard, composed primarily of gypsum plaster sandwiched between paper layers, offers excellent fire resistance and moisture control, making it ideal for interior walls and ceilings. Cement wallboard consists of a cement mixture reinforced with glass fiber mats, providing superior durability and resistance to water and impact, suitable for wet areas and exterior applications. Both materials serve as essential substrates in construction, with gypsum wallboard favored for ease of installation and finish, while cement wallboard excels in longevity and structural performance.

Composition and Material Properties

Gypsum wallboard consists primarily of a core of hydrated calcium sulfate dihydrate (gypsum) sandwiched between layers of paper, offering fire resistance and ease of installation but limited moisture resistance. Cement wallboard is made of a cementitious core often reinforced with cellulose or glass fibers, providing superior durability, high moisture resistance, and strength in comparison to gypsum. The inorganic cement matrix in cement wallboard resists mold and water damage, making it suitable for exterior or wet applications where gypsum's absorbent core would degrade.

Weight and Thickness Comparison

Gypsum wallboard typically weighs around 1.6 pounds per square foot and is available in thicknesses ranging from 1/4 inch to 5/8 inch, making it lightweight and easy to handle for interior applications. Cement wallboard, also known as cement backer board, is significantly heavier at approximately 3 to 4 pounds per square foot and comes in standard thicknesses of 1/4 inch and 1/2 inch, designed for durability in wet or exterior environments. The weight difference impacts installation ease, with gypsum favored for faster handling and cement wallboard chosen for strength and moisture resistance.

Installation Process Differences

Gypsum wallboard installation involves lightweight panels that are easily cut with a utility knife and typically attached using nails or screws to wood or metal studs, allowing for faster handling and minimal drying time. Cement wallboard requires more precise cutting tools such as a wet saw or carbide-tipped blade due to its dense composition and is fastened with specialized corrosion-resistant screws; it demands a slurry or concrete-based joint compound that cures slowly, increasing overall installation time. Moisture resistance differences in cement wallboard make it suitable for wet environments, but its heavier weight and installation complexity require more labor and expertise compared to gypsum wallboard.

Durability and Longevity

Gypsum wallboard offers ease of installation and cost-effectiveness but generally has lower durability compared to cement wallboard, which provides superior resistance to moisture, impact, and fire. Cement wallboard, made from a combination of cement and reinforcing fibers, typically lasts longer in high-traffic or wet environments such as bathrooms and kitchens. Its enhanced longevity and structural strength make cement wallboard a preferred choice for projects requiring long-term durability and resistance to harsh conditions.

Moisture and Fire Resistance

Gypsum wallboard offers excellent fire resistance due to its non-combustible core and inherent moisture barrier, making it ideal for interior applications in dry environments. Cement wallboard surpasses gypsum in moisture resistance, featuring a dense, water-resistant composition suitable for high-humidity areas and exterior use. Choosing between gypsum and cement wallboard depends on prioritizing fire protection or enhanced moisture durability in construction projects.

Sound Insulation Capabilities

Gypsum wallboard typically offers moderate sound insulation, with a Noise Reduction Coefficient (NRC) around 0.3 to 0.5, making it suitable for standard interior walls. Cement wallboard provides enhanced soundproofing due to its higher density and rigidity, achieving NRC values up to 0.6 or more, which effectively reduces noise transmission in high-traffic or moisture-prone areas. The mass and stiffness of cement wallboard contribute significantly to its superior acoustic performance compared to gypsum wallboard.

Cost Analysis: Gypsum vs Cement Wallboard

Gypsum wallboard generally offers lower initial costs compared to cement wallboard, making it a budget-friendly option for interior walls and ceilings. Cement wallboard, while more expensive upfront, provides superior durability and moisture resistance, reducing long-term maintenance and replacement expenses. Evaluating total lifecycle costs highlights gypsum's affordability for dry environments, whereas cement wallboard is cost-effective in high-moisture or exterior applications due to its longevity.

Best Use Cases for Each Wallboard Type

Gypsum wallboard excels in interior applications such as bedrooms, living rooms, and offices due to its lightweight nature, ease of installation, and superior fire resistance. Cement wallboard is ideal for wet or high-moisture environments like bathrooms, kitchens, and exterior facades, offering enhanced durability, mold resistance, and structural strength. Selecting gypsum wallboard optimizes cost-efficiency and smooth finishes, while cement wallboard ensures longevity and resilience in demanding conditions.

Environmental Impact and Sustainability

Gypsum wallboard typically has a lower environmental impact due to its recyclability and lower embodied energy compared to cement wallboard, which requires high-energy production processes involving cement and other minerals. Cement wallboard offers greater durability and moisture resistance but often results in higher carbon emissions and resource depletion during manufacturing. Choosing gypsum wallboard supports sustainable construction by reducing landfill waste and promoting the use of abundant natural gypsum resources.

Gypsum wallboard vs Cement wallboard Infographic

materialdif.com

materialdif.com