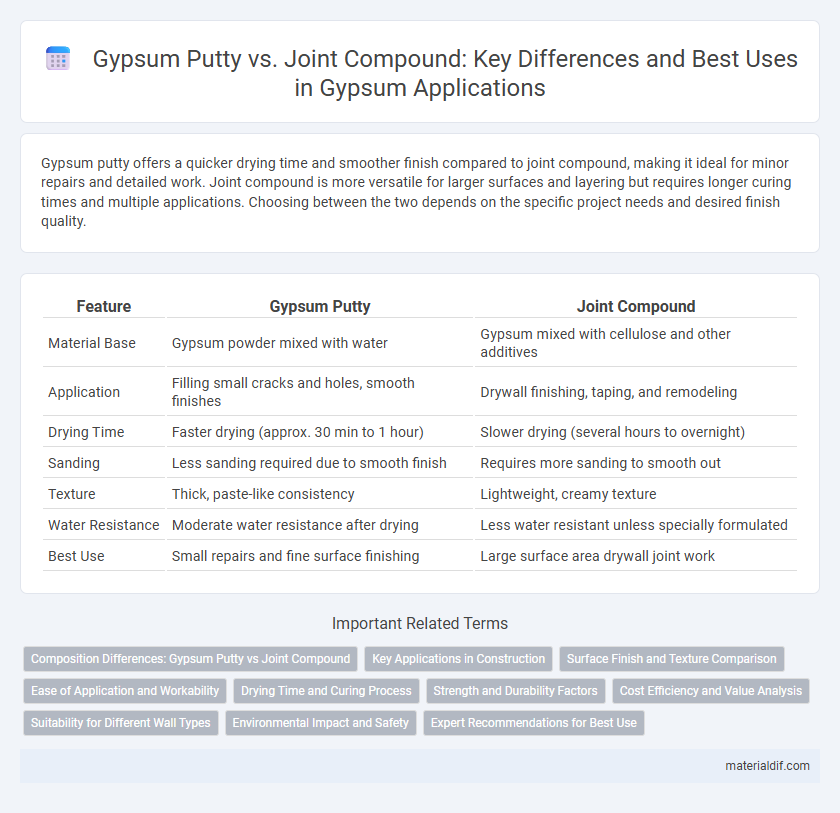

Gypsum putty offers a quicker drying time and smoother finish compared to joint compound, making it ideal for minor repairs and detailed work. Joint compound is more versatile for larger surfaces and layering but requires longer curing times and multiple applications. Choosing between the two depends on the specific project needs and desired finish quality.

Table of Comparison

| Feature | Gypsum Putty | Joint Compound |

|---|---|---|

| Material Base | Gypsum powder mixed with water | Gypsum mixed with cellulose and other additives |

| Application | Filling small cracks and holes, smooth finishes | Drywall finishing, taping, and remodeling |

| Drying Time | Faster drying (approx. 30 min to 1 hour) | Slower drying (several hours to overnight) |

| Sanding | Less sanding required due to smooth finish | Requires more sanding to smooth out |

| Texture | Thick, paste-like consistency | Lightweight, creamy texture |

| Water Resistance | Moderate water resistance after drying | Less water resistant unless specially formulated |

| Best Use | Small repairs and fine surface finishing | Large surface area drywall joint work |

Composition Differences: Gypsum Putty vs Joint Compound

Gypsum putty primarily consists of calcium sulfate hemihydrate mixed with water and fillers to form a dense, smooth paste ideal for fine surface finishing. Joint compound contains gypsum as a base but is formulated with added ingredients like fibers, binders, and vinyl polymers to enhance flexibility, drying time, and sanding properties. These composition differences result in gypsum putty offering better crack resistance and durability, while joint compound provides easier application and smoother sanding for drywall finishing.

Key Applications in Construction

Gypsum putty is primarily used for filling small cracks, holes, and surface imperfections on walls and ceilings due to its fine texture and quick drying properties. Joint compound serves as a versatile material for embedding drywall tape, smoothing joints between gypsum boards, and creating finished surfaces with excellent workability and sanding ability. Construction projects often select gypsum putty for detailed repairs, while joint compound is favored for larger-scale drywall installation and finishing tasks.

Surface Finish and Texture Comparison

Gypsum putty provides a smoother and denser surface finish compared to joint compound, making it ideal for achieving a polished look on walls and ceilings. The putty's finer texture fills small imperfections effectively, resulting in minimal sanding and a uniform appearance. Joint compound, while easier to work with, tends to have a coarser texture that may require additional layers and sanding to match the smoothness offered by gypsum putty.

Ease of Application and Workability

Gypsum putty offers superior ease of application due to its smooth, creamy consistency, making it ideal for quick repairs and detailed work on small surfaces. Joint compound, while versatile for larger drywall projects, tends to have a thicker texture that requires more effort to spread evenly and may need additional water to achieve optimal workability. The fast-drying nature of gypsum putty enhances efficiency in finishing tasks, whereas joint compound often requires longer drying times and multiple coats for a seamless finish.

Drying Time and Curing Process

Gypsum putty typically dries faster than joint compound, often within a few hours, making it ideal for quick repairs and surface finishing. The curing process of gypsum putty involves rapid setting due to its chemical composition, allowing it to harden quickly and be sanded or painted sooner. In contrast, joint compound requires longer drying and curing times, sometimes up to 24 hours or more, depending on thickness and environmental conditions, resulting in a slower overall project completion.

Strength and Durability Factors

Gypsum putty offers higher compressive strength and superior adhesion compared to joint compound, making it ideal for repairs requiring enhanced durability. Joint compound, primarily designed for finishing drywall joints, has a softer texture and lower resistance to impact and moisture. For structural reinforcement and long-lasting repairs, gypsum putty provides better performance due to its denser composition and faster curing time.

Cost Efficiency and Value Analysis

Gypsum putty generally offers higher cost efficiency due to its faster drying time and smoother finish, reducing labor costs in drywall repairs. Joint compound, while slightly cheaper per unit, requires multiple coats and longer drying periods, increasing overall project duration and labor expenses. Considering value, gypsum putty provides superior durability and less shrinkage, making it a more economical choice for high-quality, time-sensitive applications.

Suitability for Different Wall Types

Gypsum putty is ideal for smooth, indoor surfaces such as drywall and plaster walls, providing a hard, durable finish suitable for small repairs and fine detailing. Joint compound offers greater flexibility and is better suited for larger wall areas, including drywall seams and textured surfaces, due to its spreadability and ease of sanding. Different wall types demand specific materials; gypsum putty excels in high-strength repairs on rigid substrates, while joint compound adapts well to flexible, expansive drywall applications.

Environmental Impact and Safety

Gypsum putty typically contains fewer volatile organic compounds (VOCs) compared to traditional joint compound, resulting in lower indoor air pollution and improved safety for applicators. Joint compound often involves talc and silica, which pose respiratory risks if inhaled during sanding or mixing, necessitating protective measures. Environmentally, gypsum putty's faster drying and minimal waste generation contribute to reduced resource consumption and carbon footprint relative to joint compound.

Expert Recommendations for Best Use

Experts recommend gypsum putty for quick, small repairs and smooth finishes on plaster or drywall due to its fast drying time and ease of application. Joint compound is favored for larger projects involving multiple layers, sanding, and painting because of its superior workability and ability to fill gaps and joints effectively. For optimal results, professionals advise using gypsum putty on minor cosmetic fixes and joint compound for comprehensive drywall finishing and texturing tasks.

Gypsum putty vs Joint compound Infographic

materialdif.com

materialdif.com