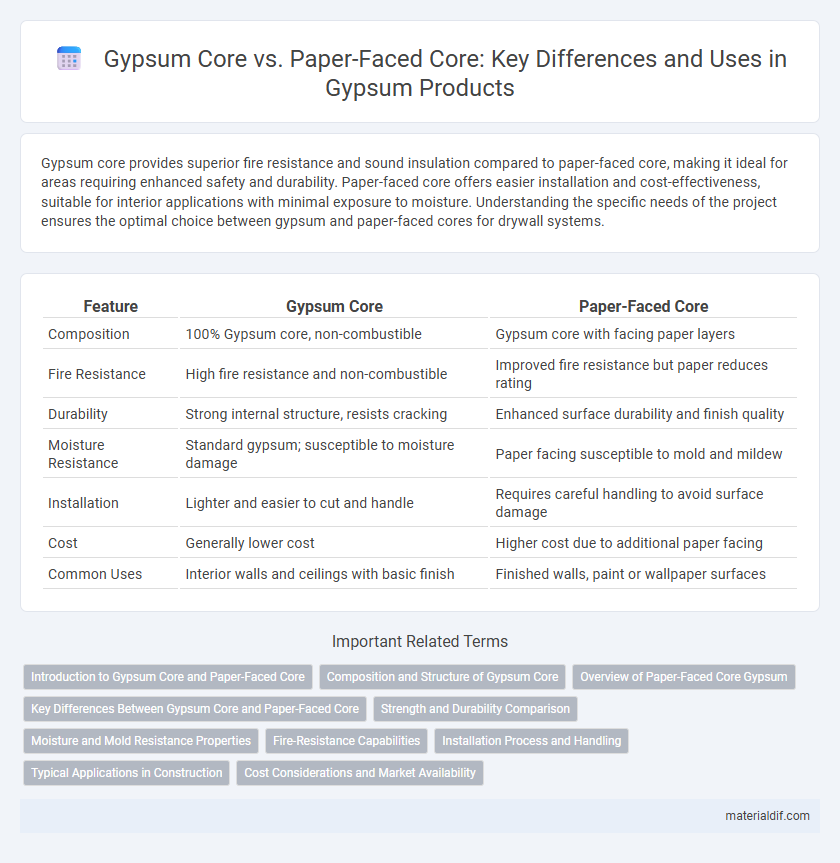

Gypsum core provides superior fire resistance and sound insulation compared to paper-faced core, making it ideal for areas requiring enhanced safety and durability. Paper-faced core offers easier installation and cost-effectiveness, suitable for interior applications with minimal exposure to moisture. Understanding the specific needs of the project ensures the optimal choice between gypsum and paper-faced cores for drywall systems.

Table of Comparison

| Feature | Gypsum Core | Paper-Faced Core |

|---|---|---|

| Composition | 100% Gypsum core, non-combustible | Gypsum core with facing paper layers |

| Fire Resistance | High fire resistance and non-combustible | Improved fire resistance but paper reduces rating |

| Durability | Strong internal structure, resists cracking | Enhanced surface durability and finish quality |

| Moisture Resistance | Standard gypsum; susceptible to moisture damage | Paper facing susceptible to mold and mildew |

| Installation | Lighter and easier to cut and handle | Requires careful handling to avoid surface damage |

| Cost | Generally lower cost | Higher cost due to additional paper facing |

| Common Uses | Interior walls and ceilings with basic finish | Finished walls, paint or wallpaper surfaces |

Introduction to Gypsum Core and Paper-Faced Core

Gypsum core consists of a mineral-based interior made from gypsum plaster, providing fire resistance, sound insulation, and structural strength commonly used in drywall and plasterboard manufacturing. Paper-faced core features a gypsum core wrapped in specially formulated paper sheets that enhance durability, surface finish, and ease of installation while maintaining moisture resistance and flexibility. Both core types are essential in construction for walls and ceilings, with gypsum core prioritizing core material properties and paper-faced core emphasizing exterior surface quality.

Composition and Structure of Gypsum Core

Gypsum core is primarily composed of a dense, non-combustible gypsum mineral mixed with reinforcing fibers for added strength, providing excellent fire resistance and sound insulation properties. Unlike paper-faced cores, the gypsum core itself serves as the main structural component, offering rigidity and durability without reliance on external facings. The internal crystalline structure of the gypsum core ensures moisture resistance and dimensional stability, making it ideal for a variety of building applications.

Overview of Paper-Faced Core Gypsum

Paper-faced core gypsum consists of a gypsum core encased in specially designed paper that enhances durability, moisture resistance, and fire retardance. This type of gypsum board is widely used in interior wall systems due to its smooth finish, ease of installation, and improved surface adhesion for paints and finishes. The paper facing also helps protect the core from damage during handling and contributes to overall structural integrity.

Key Differences Between Gypsum Core and Paper-Faced Core

Gypsum core consists primarily of a solid gypsum core sandwiched between paper facings, providing fire resistance, soundproofing, and moisture control, whereas paper-faced core refers to the paper layers themselves that encase the gypsum. Gypsum core offers enhanced structural strength and durability, making it integral for drywall and gypsum board applications, while paper-faced cores mainly contribute to surface finish and attachment properties. The key differences lie in their composition and function: gypsum core delivers core properties like fire resistance, while paper-faced core influences surface texture and installation performance.

Strength and Durability Comparison

Gypsum core offers excellent fire resistance and sound insulation but tends to be more brittle and prone to damage under impact compared to paper-faced core, which is reinforced with a durable paper layer enhancing its tensile strength and flexibility. Paper-faced core provides improved resistance to cracking and moisture, making it more suitable for high-traffic or humid environments. Strength and durability metrics consistently show paper-faced gypsum boards outperform gypsum-only cores in terms of impact resistance and long-term structural integrity.

Moisture and Mold Resistance Properties

Gypsum core boards typically offer better moisture resistance compared to paper-faced cores, as the paper facing on gypsum board can absorb water and promote mold growth under high humidity conditions. Mold resistance in gypsum core products is enhanced by additives like fiberglass mats and moisture-resistant core treatments that prevent fungal development. Selecting moisture-resistant gypsum cores with specialized facings significantly improves durability in damp environments such as bathrooms and basements.

Fire-Resistance Capabilities

Gypsum core offers superior fire-resistance capabilities due to its dense composition and ability to absorb heat, effectively slowing fire spread and maintaining structural integrity. Paper-faced core, while providing basic fire protection, is less effective as the paper layer can ignite and degrade under high temperatures, compromising the overall fire resistance of the material. Fire-rated gypsum boards with non-combustible cores are preferred in construction for enhanced safety and compliance with fire codes.

Installation Process and Handling

Gypsum core boards feature a solid gypsum center that provides lightweight ease during installation but requires careful handling to prevent breakage and dust generation. Paper-faced core drywall incorporates a gypsum core encased in paper, offering enhanced rigidity and reduced dust, making it easier to cut and install with fewer protective measures. Both types demand precise measurement and secure fastening, but paper-faced core panels generally streamline handling and reduce installation time due to their durability and cleaner edges.

Typical Applications in Construction

Gypsum core is widely used in interior wall and ceiling systems for residential and commercial buildings due to its fire resistance, sound insulation, and moisture control properties. Paper-faced core drywall enhances structural rigidity and provides a smooth surface for finishing, making it ideal for walls and ceilings requiring paint or wallpaper application. Both cores serve distinct roles in construction, with gypsum core favored for its durability in damp environments and paper-faced core preferred for aesthetic and finishing purposes.

Cost Considerations and Market Availability

Gypsum core boards typically offer a lower cost option compared to paper-faced core boards due to simpler manufacturing processes and fewer materials involved. Paper-faced core boards, often preferred for enhanced durability and finish, tend to have higher market availability in premium construction sectors but come at a premium price. Cost considerations should balance initial budget constraints with long-term performance needs, as gypsum core is widely available in standard framing projects while paper-faced cores dominate specialized architectural applications.

Gypsum core vs Paper-faced core Infographic

materialdif.com

materialdif.com