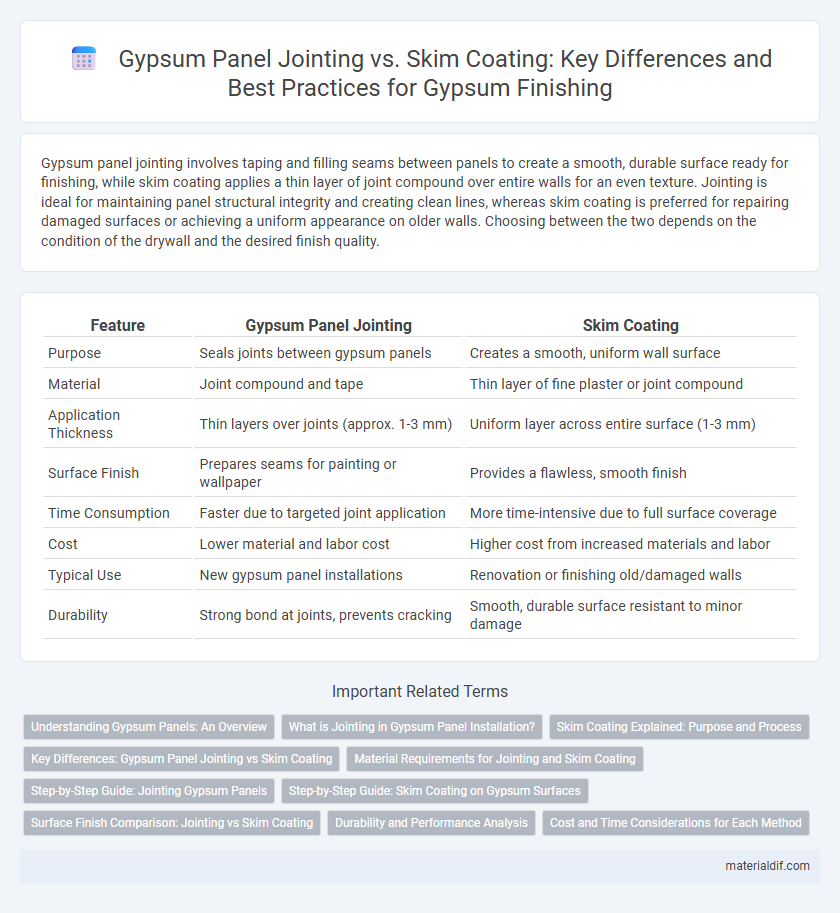

Gypsum panel jointing involves taping and filling seams between panels to create a smooth, durable surface ready for finishing, while skim coating applies a thin layer of joint compound over entire walls for an even texture. Jointing is ideal for maintaining panel structural integrity and creating clean lines, whereas skim coating is preferred for repairing damaged surfaces or achieving a uniform appearance on older walls. Choosing between the two depends on the condition of the drywall and the desired finish quality.

Table of Comparison

| Feature | Gypsum Panel Jointing | Skim Coating |

|---|---|---|

| Purpose | Seals joints between gypsum panels | Creates a smooth, uniform wall surface |

| Material | Joint compound and tape | Thin layer of fine plaster or joint compound |

| Application Thickness | Thin layers over joints (approx. 1-3 mm) | Uniform layer across entire surface (1-3 mm) |

| Surface Finish | Prepares seams for painting or wallpaper | Provides a flawless, smooth finish |

| Time Consumption | Faster due to targeted joint application | More time-intensive due to full surface coverage |

| Cost | Lower material and labor cost | Higher cost from increased materials and labor |

| Typical Use | New gypsum panel installations | Renovation or finishing old/damaged walls |

| Durability | Strong bond at joints, prevents cracking | Smooth, durable surface resistant to minor damage |

Understanding Gypsum Panels: An Overview

Gypsum panel jointing involves sealing the gaps between panels using joint compound and tape to create a smooth, uniform surface ready for decoration. Skim coating applies a thin layer of finishing plaster over entire gypsum surfaces, providing enhanced durability and a flawless finish. Understanding the differences in preparation techniques helps optimize drywall installation quality and long-term maintenance.

What is Jointing in Gypsum Panel Installation?

Jointing in gypsum panel installation involves filling and sealing the gaps between individual panels using joint compound, tape, and sometimes corner beads to create a smooth, uniform surface. This process enhances structural integrity, prevents cracks, and prepares the surface for painting or further finishing. Unlike skim coating, jointing focuses specifically on the seams rather than covering the entire wall surface.

Skim Coating Explained: Purpose and Process

Skim coating is a finishing technique applied to gypsum panels to create a smooth, seamless surface free of joints and imperfections. This process involves spreading a thin layer of joint compound over the entire panel surface, which enhances the wall's durability and improves paint adhesion. Skim coating minimizes visible seams and imperfections more effectively than traditional jointing, making it ideal for achieving a high-quality, polished finish.

Key Differences: Gypsum Panel Jointing vs Skim Coating

Gypsum panel jointing involves filling and sealing the joints between gypsum boards with specialized compounds to create a smooth, continuous surface, ensuring structural integrity and preventing cracks. Skim coating is a thin layer of finishing plaster applied over entire surfaces, including gypsum panels, to achieve a uniformly smooth and flawless finish. The key difference lies in jointing targeting only seams and repairs, while skim coating transforms the entire wall texture for enhanced aesthetics and durability.

Material Requirements for Jointing and Skim Coating

Gypsum panel jointing requires joint compound, joint tape, and corner beads to ensure seamless connections between panels, focusing on filling gaps and reinforcing joints. Skim coating demands a fine, smooth gypsum-based finishing plaster or compound applied in thin layers to create a uniform surface ready for painting or decoration. Both techniques rely on different material properties: jointing materials prioritize adhesion and crack resistance, while skim coatings emphasize smoothness and surface refinement.

Step-by-Step Guide: Jointing Gypsum Panels

Jointing gypsum panels involves embedding joint tape into a layer of joint compound, applying multiple coats to create a smooth, seamless surface, and sanding between applications for a flawless finish. This method provides greater durability and crack resistance compared to skim coating, which simply involves applying a thin layer of compound over the entire surface. Professional jointing ensures optimal adhesion and long-lasting results in drywall installation and repair.

Step-by-Step Guide: Skim Coating on Gypsum Surfaces

Skim coating on gypsum surfaces involves applying a thin, smooth layer of joint compound to create an even finish, enhancing durability and paint adherence compared to traditional gypsum panel jointing. Start by cleaning and priming the gypsum panels, then apply the first thin coat of joint compound using a wide drywall knife, allowing it to dry completely before sanding lightly. Follow with subsequent coats, gradually building a flawless surface, finishing with fine sanding to ensure a smooth, paint-ready finish without visible seams or imperfections.

Surface Finish Comparison: Jointing vs Skim Coating

Gypsum panel jointing involves filling and sanding seams to create a smooth base, while skim coating applies a thin, uniform layer of joint compound over the entire surface for enhanced texture consistency. Jointing targets only the gaps and fastener holes, resulting in less material usage but potentially visible imperfections under certain lighting conditions. Skim coating delivers a superior, polished finish that better conceals surface irregularities and offers increased durability for high-visibility applications.

Durability and Performance Analysis

Gypsum panel jointing offers superior durability by providing strong, crack-resistant seams through reinforced joint tapes and compounds, ensuring long-lasting performance under structural stress. Skim coating, while enhancing surface smoothness and aesthetic appeal, is less effective in concealing joint weaknesses and prone to cracking over time due to its thinner application. Performance analysis confirms that gypsum panel jointing maintains structural integrity and reduces maintenance needs more effectively than skim coating in high-traffic or high-moisture environments.

Cost and Time Considerations for Each Method

Gypsum panel jointing typically offers a cost-effective solution with faster application times compared to skim coating, as it involves taping and filling seams rather than covering entire surfaces. Skim coating requires more skilled labor and extended drying periods, increasing both time and expense, but delivers a smoother, more uniform finish ideal for high-quality decorative surfaces. Choosing between the two depends on project budget constraints and desired aesthetic outcomes, with jointing preferred for rapid installation and skim coating favored for premium surface refinement.

Gypsum panel jointing vs Skim coating Infographic

materialdif.com

materialdif.com