Gypsum blocks offer excellent fire resistance and sound insulation, making them ideal for interior partition walls in residential and commercial buildings. AAC blocks provide superior thermal insulation and load-bearing capacity, which enhances energy efficiency and structural stability. Both materials are lightweight and easy to install, but AAC blocks tend to have higher compressive strength compared to gypsum blocks.

Table of Comparison

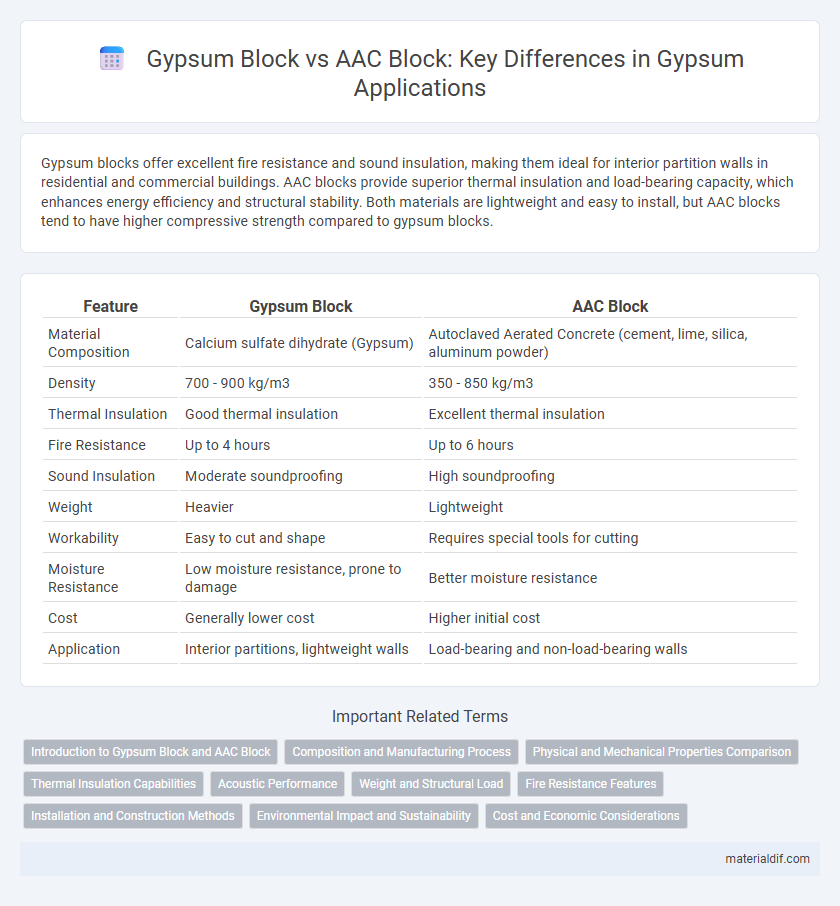

| Feature | Gypsum Block | AAC Block |

|---|---|---|

| Material Composition | Calcium sulfate dihydrate (Gypsum) | Autoclaved Aerated Concrete (cement, lime, silica, aluminum powder) |

| Density | 700 - 900 kg/m3 | 350 - 850 kg/m3 |

| Thermal Insulation | Good thermal insulation | Excellent thermal insulation |

| Fire Resistance | Up to 4 hours | Up to 6 hours |

| Sound Insulation | Moderate soundproofing | High soundproofing |

| Weight | Heavier | Lightweight |

| Workability | Easy to cut and shape | Requires special tools for cutting |

| Moisture Resistance | Low moisture resistance, prone to damage | Better moisture resistance |

| Cost | Generally lower cost | Higher initial cost |

| Application | Interior partitions, lightweight walls | Load-bearing and non-load-bearing walls |

Introduction to Gypsum Block and AAC Block

Gypsum blocks are made from natural gypsum plaster, offering excellent fire resistance, sound insulation, and ease of installation for interior partitions. AAC (Autoclaved Aerated Concrete) blocks are lightweight, cellular concrete units known for high thermal insulation, structural strength, and eco-friendly properties. Both materials serve as alternatives to traditional masonry, with gypsum blocks preferred for smooth finishes and AAC blocks favored for load-bearing walls and energy efficiency.

Composition and Manufacturing Process

Gypsum blocks are primarily made from hydrated calcium sulfate derived from natural or synthetic gypsum, processed by mixing with water and additives before being molded and steam-cured. AAC blocks consist of a mixture of cement, lime, sand, water, and aluminum powder, which reacts to produce tiny air bubbles, resulting in lightweight, autoclaved aerated concrete cured under high pressure and temperature. The manufacturing process of gypsum blocks involves hydration and setting in molds, while AAC blocks undergo a chemical foaming reaction followed by autoclaving for enhanced strength and insulation properties.

Physical and Mechanical Properties Comparison

Gypsum blocks exhibit lower density, typically around 900-1100 kg/m3, compared to AAC (Autoclaved Aerated Concrete) blocks which range from 500-700 kg/m3, making AAC blocks lighter and easier for handling and transportation. Mechanically, gypsum blocks have a compressive strength of approximately 3-6 MPa, while AAC blocks generally offer higher compressive strength values between 3.5-7 MPa, contributing to better load-bearing capacity. Both materials provide good thermal insulation, but AAC blocks tend to have superior fire resistance and soundproofing, influencing their application based on structural and environmental requirements.

Thermal Insulation Capabilities

Gypsum blocks provide moderate thermal insulation with a typical thermal conductivity of around 0.17-0.21 W/mK, making them suitable for interior partition walls where temperature regulation is needed. AAC (Autoclaved Aerated Concrete) blocks offer superior thermal insulation due to their porous structure, exhibiting thermal conductivity values as low as 0.09-0.14 W/mK, which significantly reduces heat transfer and enhances energy efficiency in buildings. The lower density and higher porosity of AAC blocks make them more effective in maintaining indoor temperature stability compared to gypsum blocks.

Acoustic Performance

Gypsum blocks offer superior acoustic performance due to their dense, non-porous structure, which effectively absorbs and dampens sound transmission. AAC (Autoclaved Aerated Concrete) blocks, while lightweight and thermally efficient, have a more porous composition that allows higher sound permeability. For projects prioritizing sound insulation, gypsum blocks provide enhanced noise reduction compared to AAC blocks.

Weight and Structural Load

Gypsum blocks are significantly lighter than AAC blocks, typically weighing around 800-1000 kg/m3 compared to AAC's 400-700 kg/m3, which reduces the structural load on foundations and frameworks. The lower density of gypsum blocks results in easier handling and faster installation, while AAC blocks, despite being heavier, provide superior thermal and acoustic insulation. Choosing between gypsum and AAC blocks depends on balancing the benefits of reduced weight with the required structural performance and insulation needs in construction projects.

Fire Resistance Features

Gypsum blocks exhibit superior fire resistance due to their chemical composition, which includes water molecules that release steam when heated, effectively slowing fire spread. AAC (Autoclaved Aerated Concrete) blocks also offer excellent fire resistance with a fire rating of up to 4 hours, but gypsum blocks provide enhanced thermal insulation properties, reducing heat transfer. Both materials are non-combustible, but gypsum blocks are often preferred in fire-prone environments for their ability to maintain structural integrity under high temperatures.

Installation and Construction Methods

Gypsum blocks enable faster installation due to their lighter weight and ease of cutting with standard tools, reducing labor time and costs compared to AAC blocks. AAC blocks require wet mortar for bonding and precise curing time, whereas gypsum blocks can be installed with dry jointing techniques, enhancing construction speed. Both materials offer fire resistance and sound insulation, but gypsum blocks allow more flexibility in interior partition wall designs due to their smooth surface and straightforward fixing methods.

Environmental Impact and Sustainability

Gypsum blocks are made from natural gypsum, a readily available mineral, which results in lower embodied energy and reduced CO2 emissions compared to AAC (Autoclaved Aerated Concrete) blocks that require significant energy for production. Gypsum blocks offer excellent recyclability and contribute to waste reduction, while AAC blocks, despite their thermal efficiency and lighter weight, involve energy-intensive processes including autoclaving and the use of cement. Choosing gypsum blocks supports sustainability goals by minimizing environmental footprint through lower resource consumption and enhanced material lifecycle benefits.

Cost and Economic Considerations

Gypsum blocks generally have a lower initial cost compared to AAC blocks, making them a budget-friendly option for interior partition walls. AAC blocks, while more expensive upfront, offer better thermal insulation and durability, potentially reducing long-term energy and maintenance expenses. Evaluating project requirements and lifecycle costs is essential to determine the most economical choice between gypsum and AAC blocks.

Gypsum block vs AAC block Infographic

materialdif.com

materialdif.com