Gypsum casting offers precise mold replication and creates solid, detailed structures ideal for intricate designs, whereas gypsum spraying provides a faster application method suitable for large surfaces and textured finishes. Casting requires more time and careful preparation but results in higher strength and durability, while spraying emphasizes efficiency and ease of use. Choosing between gypsum casting and spraying depends on the project's complexity, desired finish quality, and production speed.

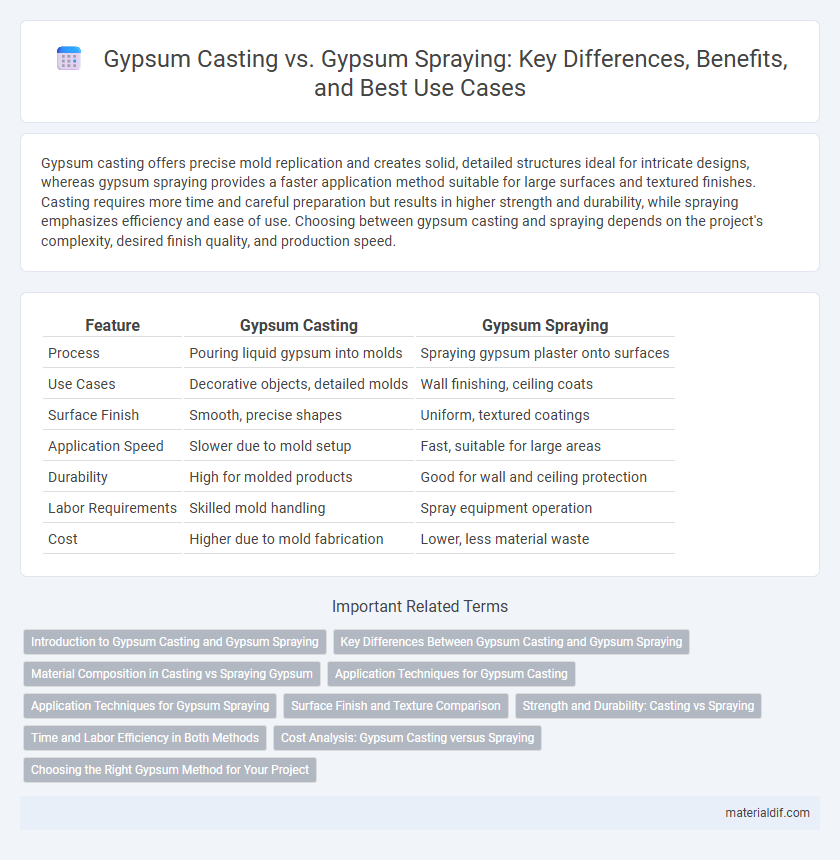

Table of Comparison

| Feature | Gypsum Casting | Gypsum Spraying |

|---|---|---|

| Process | Pouring liquid gypsum into molds | Spraying gypsum plaster onto surfaces |

| Use Cases | Decorative objects, detailed molds | Wall finishing, ceiling coats |

| Surface Finish | Smooth, precise shapes | Uniform, textured coatings |

| Application Speed | Slower due to mold setup | Fast, suitable for large areas |

| Durability | High for molded products | Good for wall and ceiling protection |

| Labor Requirements | Skilled mold handling | Spray equipment operation |

| Cost | Higher due to mold fabrication | Lower, less material waste |

Introduction to Gypsum Casting and Gypsum Spraying

Gypsum casting involves pouring a liquid gypsum mixture into molds to create detailed and precise shapes, commonly used in decorative arts and construction for producing intricate architectural elements. Gypsum spraying applies a gypsum slurry directly onto surfaces using spray equipment, enabling quick coverage and smooth finishing ideal for wallboarding and ceiling coatings. Both techniques utilize gypsum's fast-setting properties but differ significantly in application methods and end-use, impacting durability and surface texture.

Key Differences Between Gypsum Casting and Gypsum Spraying

Gypsum casting involves pouring a liquid gypsum mixture into molds to create precise, detailed shapes used in architectural elements and art, whereas gypsum spraying applies a dry gypsum powder mixed with water directly onto surfaces for rapid coating and finishing. Casting offers superior dimensional accuracy and strength ideal for intricate designs, while spraying excels in speed and efficiency for covering large areas with a smooth, even layer. The choice between these methods depends on the specific application requirements, with casting suited for decorative components and spraying preferred for quick surface treatment.

Material Composition in Casting vs Spraying Gypsum

Gypsum casting primarily utilizes a denser mix of calcium sulfate hemihydrate and water, often enhanced with additives to improve setting time and surface smoothness. In contrast, gypsum spraying involves a lighter, more fluid composition with added binders and aerators to ensure better adhesion and sprayability on vertical surfaces. The material composition differences directly impact the final product's texture, strength, and application method efficiency.

Application Techniques for Gypsum Casting

Gypsum casting involves pouring a liquid gypsum mixture into molds to create detailed, precise shapes commonly used in decorative elements, sculptures, and architectural details. This technique allows for high accuracy and smooth finishes, making it ideal for reproducing intricate designs and fine textures. The controlled environment of casting ensures consistent quality and durability in the final product compared to spraying methods.

Application Techniques for Gypsum Spraying

Gypsum spraying employs high-pressure equipment to evenly apply a consistent layer of gypsum plaster directly onto surfaces, ensuring rapid adhesion and uniform thickness. This technique enhances efficiency for large-scale wall and ceiling coatings, reducing manual labor compared to traditional casting methods. The spraying process also offers superior control over texture and finish, making it ideal for complex architectural designs and fast setting requirements.

Surface Finish and Texture Comparison

Gypsum casting produces smooth, dense surfaces ideal for detailed molds and fine textures, offering high precision in decorative elements. Gypsum spraying results in a more porous, textured finish suited for broader coverage and faster application but less detailed surface quality. Surface finish from casting is typically glossy and uniform, while sprayed gypsum textures exhibit a matte, rougher appearance with enhanced adhesion properties.

Strength and Durability: Casting vs Spraying

Gypsum casting produces denser and more uniform structures, resulting in higher strength and greater durability compared to gypsum spraying. Sprayed gypsum tends to have a more porous texture, which can reduce its resistance to impact and wear over time. The compactness achieved in casting makes it preferable for applications demanding long-term structural integrity.

Time and Labor Efficiency in Both Methods

Gypsum casting requires longer setting times and involves more manual labor for mold preparation and demolding, leading to extended project durations. Gypsum spraying significantly reduces application time by allowing rapid and uniform layering, which minimizes labor intensity and accelerates overall workflow. Choosing spraying over casting enhances time efficiency and labor productivity in construction and decorative applications.

Cost Analysis: Gypsum Casting versus Spraying

Gypsum casting typically involves higher initial setup costs due to mold fabrication and material preparation, but it offers precise shapes and smooth finishes ideal for intricate designs. Gypsum spraying reduces labor and mold expenses by applying a plaster mixture directly onto surfaces, leading to lower overall operational costs in large-scale or irregular applications. Cost efficiency depends on project scale and complexity, with casting favored for detail and spraying preferred for speed and reduced material waste.

Choosing the Right Gypsum Method for Your Project

Gypsum casting offers precise mold replication and strength ideal for detailed architectural elements, while gypsum spraying provides quick application and uniform coverage suited for large surface areas or fast renovations. Selecting the right gypsum method depends on project requirements such as intricacy, time constraints, and surface type, with casting favored for sculptural finishes and spraying for efficient wall coatings. Understanding the compatibility of gypsum material with your substrate ensures optimal durability and aesthetic results in both techniques.

Gypsum Casting vs Gypsum Spraying Infographic

materialdif.com

materialdif.com