Fiberglass reinforced gypsum offers enhanced durability and moisture resistance compared to standard gypsum, making it ideal for high-humidity environments. Its composite structure improves impact strength and reduces the risk of cracking, extending the lifespan of drywall installations. Standard gypsum, while cost-effective and easy to install, lacks these reinforcement properties, limiting its use in areas prone to moisture and physical stress.

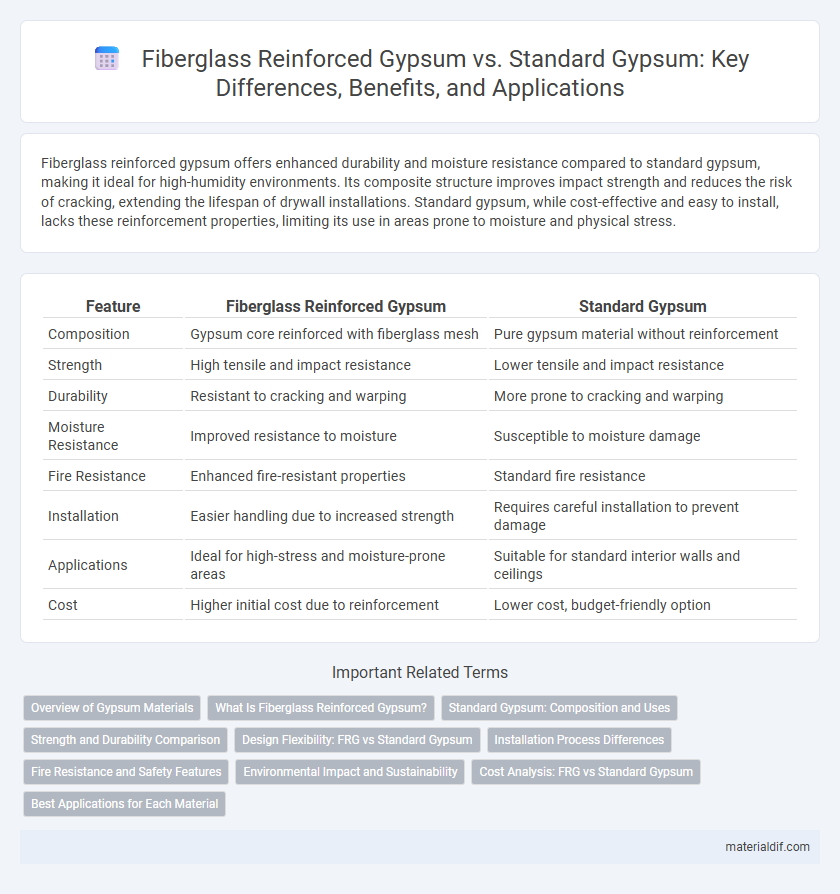

Table of Comparison

| Feature | Fiberglass Reinforced Gypsum | Standard Gypsum |

|---|---|---|

| Composition | Gypsum core reinforced with fiberglass mesh | Pure gypsum material without reinforcement |

| Strength | High tensile and impact resistance | Lower tensile and impact resistance |

| Durability | Resistant to cracking and warping | More prone to cracking and warping |

| Moisture Resistance | Improved resistance to moisture | Susceptible to moisture damage |

| Fire Resistance | Enhanced fire-resistant properties | Standard fire resistance |

| Installation | Easier handling due to increased strength | Requires careful installation to prevent damage |

| Applications | Ideal for high-stress and moisture-prone areas | Suitable for standard interior walls and ceilings |

| Cost | Higher initial cost due to reinforcement | Lower cost, budget-friendly option |

Overview of Gypsum Materials

Fiberglass reinforced gypsum (FRG) combines traditional gypsum with glass fibers, enhancing strength, durability, and resistance to cracking compared to standard gypsum. Standard gypsum, primarily composed of calcium sulfate dihydrate, offers excellent fire resistance and ease of installation but lacks the structural robustness of FRG. FRG is often used in demanding architectural applications requiring higher impact resistance and longevity.

What Is Fiberglass Reinforced Gypsum?

Fiberglass reinforced gypsum (FRG) is a composite material that combines gypsum plaster with fiberglass mats or strands to enhance durability and strength. Unlike standard gypsum, which is brittle and prone to cracking, FRG offers improved impact resistance, flexibility, and moisture tolerance. This makes FRG ideal for architectural applications such as ceiling panels, wall liners, and decorative moldings where enhanced performance and longevity are required.

Standard Gypsum: Composition and Uses

Standard gypsum primarily consists of calcium sulfate dihydrate, a naturally occurring mineral that provides excellent fire resistance and sound insulation. It is widely used in construction for drywall, plaster, and ceiling tiles due to its ease of installation and versatility. Standard gypsum's cost-effectiveness and biodegradability make it a preferred material for interior wall applications and decorative finishes.

Strength and Durability Comparison

Fiberglass reinforced gypsum exhibits significantly higher tensile strength and impact resistance compared to standard gypsum, making it ideal for applications requiring enhanced structural integrity. Its durability is improved by the incorporation of fiberglass fibers, which prevent cracking and increase resistance to water and environmental wear. Standard gypsum, while cost-effective and easy to install, is more prone to brittleness and damage under stress or moisture exposure.

Design Flexibility: FRG vs Standard Gypsum

Fiberglass reinforced gypsum (FRG) offers superior design flexibility compared to standard gypsum due to its enhanced strength and lightweight properties, allowing for intricate shapes and custom architectural details. FRG panels can be easily molded into complex forms without compromising durability, whereas standard gypsum is limited to flat or simple curved surfaces and is more prone to cracking under stress. This makes FRG ideal for high-end interior designs requiring seamless, sculptural finishes that are difficult to achieve with conventional gypsum.

Installation Process Differences

Fiberglass reinforced gypsum (FRG) offers faster installation due to its lightweight and enhanced flexibility compared to standard gypsum, which is heavier and more brittle. FRG panels typically require fewer fasteners and less finishing time because they resist cracking and warping, reducing labor and material costs. Standard gypsum demands careful handling and more time for joint taping and sanding to achieve a smooth surface.

Fire Resistance and Safety Features

Fiberglass reinforced gypsum offers superior fire resistance compared to standard gypsum due to its enhanced structural integrity and non-combustible properties, which significantly reduce flame spread and smoke generation. This material incorporates glass fibers that improve durability and prevent cracking under high temperatures, ensuring better safety in fire-prone environments. Standard gypsum typically has lower fire resistance ratings and is more susceptible to damage during fire exposure, making fiberglass reinforced gypsum a preferred choice for enhanced fire safety in building applications.

Environmental Impact and Sustainability

Fiberglass reinforced gypsum (FRG) offers enhanced environmental benefits compared to standard gypsum due to its increased durability and longer lifespan, reducing the frequency of replacement and associated waste. The incorporation of fiberglass fibers improves structural stability, decreasing material consumption and energy expenditure over time. Standard gypsum, while recyclable and abundant, tends to have a higher environmental footprint because of its lower strength and susceptibility to damage, which leads to more frequent disposal and resource use.

Cost Analysis: FRG vs Standard Gypsum

Fiberglass reinforced gypsum (FRG) typically incurs higher initial costs compared to standard gypsum due to the added materials and manufacturing complexity, with prices often ranging 20-40% above standard gypsum panels. However, FRG offers superior durability and impact resistance, reducing maintenance and replacement costs over a building's lifespan, which can lead to lower total cost of ownership. When evaluating project budgets, the upfront expense of FRG is offset by long-term savings in repair and longevity, making it a cost-effective choice for high-traffic or demanding environments.

Best Applications for Each Material

Fiberglass reinforced gypsum offers superior strength and moisture resistance, making it ideal for exterior applications such as wall panels, ceiling tiles, and moldings in humid environments. Standard gypsum, known for its affordability and ease of installation, is best suited for interior wall partitions and ceilings in dry areas where high moisture resistance is not required. Selecting the appropriate material depends on environmental exposure and structural demands to ensure durability and performance.

Fiberglass reinforced gypsum vs Standard gypsum Infographic

materialdif.com

materialdif.com