Gypsum powder is a naturally occurring mineral composed mainly of calcium sulfate dihydrate, commonly used as a raw material in construction and agriculture. Plaster of Paris is a processed form of gypsum obtained by heating gypsum powder to remove water content, resulting in a fine white powder that sets quickly upon mixing with water. The key difference lies in their applications: gypsum powder is often used for soil conditioning and cement production, while Plaster of Paris is preferred for molding, casting, and decorative work due to its fast-setting properties.

Table of Comparison

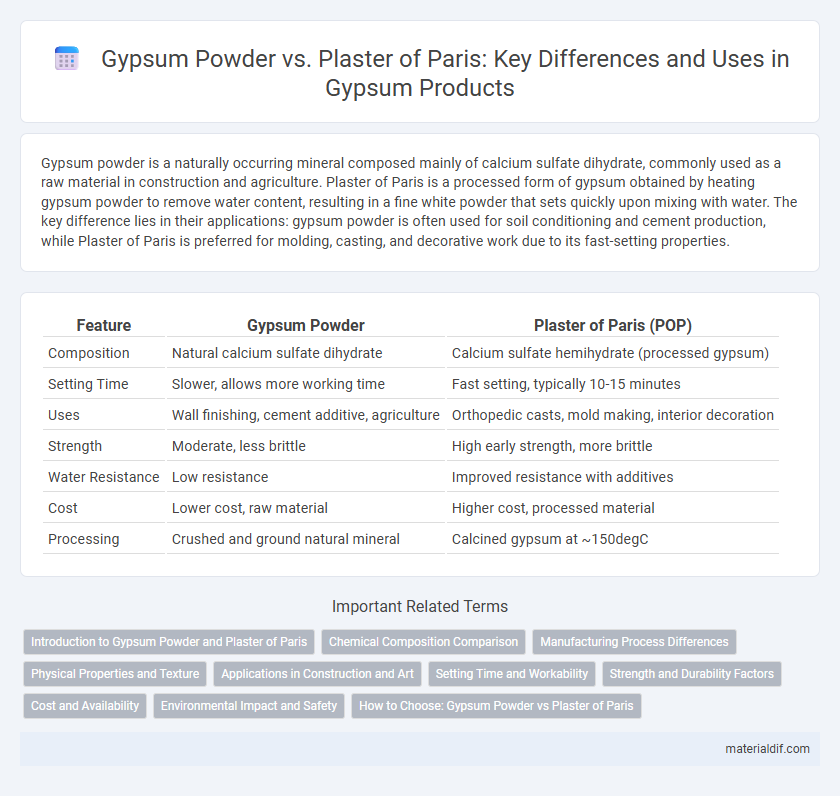

| Feature | Gypsum Powder | Plaster of Paris (POP) |

|---|---|---|

| Composition | Natural calcium sulfate dihydrate | Calcium sulfate hemihydrate (processed gypsum) |

| Setting Time | Slower, allows more working time | Fast setting, typically 10-15 minutes |

| Uses | Wall finishing, cement additive, agriculture | Orthopedic casts, mold making, interior decoration |

| Strength | Moderate, less brittle | High early strength, more brittle |

| Water Resistance | Low resistance | Improved resistance with additives |

| Cost | Lower cost, raw material | Higher cost, processed material |

| Processing | Crushed and ground natural mineral | Calcined gypsum at ~150degC |

Introduction to Gypsum Powder and Plaster of Paris

Gypsum powder, a natural mineral composed of calcium sulfate dihydrate, serves as the raw material for producing Plaster of Paris (POP), which is created by heating gypsum to remove water content. Plaster of Paris is a white, fine powder that hardens quickly when mixed with water, commonly used in construction and medical casts due to its excellent molding and setting properties. While gypsum powder remains in its natural hydrated state, POP undergoes thermal processing, making it more reactive and suitable for rapid setting applications.

Chemical Composition Comparison

Gypsum powder primarily consists of calcium sulfate dihydrate (CaSO4*2H2O), while Plaster of Paris is made by heating gypsum to remove water, resulting in calcium sulfate hemihydrate (CaSO4* 1/2H2O). This chemical difference influences their setting times and water absorption properties, with Plaster of Paris setting faster due to its hemihydrate form. The hydration reaction of Plaster of Paris reverts it back to gypsum's dihydrate state, crucial for applications requiring quick hardening and smooth finishes.

Manufacturing Process Differences

Gypsum powder is produced by crushing natural gypsum and then heating it to remove moisture, resulting in a fine, dry powder primarily composed of calcium sulfate hemihydrate. Plaster of Paris (POP) is manufactured by heating gypsum to around 150degC, which drives off water and converts it into a partially dehydrated form, allowing it to set quickly when mixed with water. The key manufacturing difference lies in the calcination temperature and moisture content, with POP undergoing a controlled heating process to achieve rapid setting properties, whereas gypsum powder retains more moisture and a looser particle structure.

Physical Properties and Texture

Gypsum powder is a naturally occurring mineral composed of calcium sulfate dihydrate, exhibiting a fine, smooth texture that enhances its workability in construction applications. Plaster of Paris, derived by heating gypsum to remove water molecules, results in a powder with a finer, more consistent particle size and a quicker setting time. The physical properties differ as gypsum powder maintains slight moisture content, providing plasticity, while Plaster of Paris hardens rapidly into a dense, brittle material ideal for molding and casting.

Applications in Construction and Art

Gypsum powder is widely used in construction for creating smooth wall surfaces, as it offers excellent workability and durability, making it suitable for drywall and plastering applications. Plaster of Paris (POP), derived from gypsum powder, is preferred in art for detailed moldings and sculptures due to its quick-setting properties and fine texture. Both materials contribute to interior finishing, but gypsum powder excels in structural applications while POP is favored for decorative and artistic detailing.

Setting Time and Workability

Gypsum powder generally has a longer setting time compared to Plaster of Paris (POP), allowing for extended workability and ease of molding in construction and sculpting applications. Plaster of Paris sets rapidly, often within 10 to 15 minutes, making it ideal for quick repairs but limiting the working time for detailed finishing. The prolonged setting time of gypsum powder enhances its versatility in complex projects, whereas POP's fast setting facilitates speedy completion but requires swift handling.

Strength and Durability Factors

Gypsum powder is the raw material from which Plaster of Paris (POP) is derived through heating and calcination, resulting in different physical properties. POP exhibits higher compressive strength due to its finer particle size and controlled setting time, making it suitable for detailed molds and interior decorative elements. However, gypsum powder-based materials demonstrate better moisture resistance and durability in structural applications, as uncalcined gypsum retains more natural hydration properties that contribute to long-term stability.

Cost and Availability

Gypsum powder is generally more cost-effective and widely available due to its natural abundance and straightforward processing methods. Plaster of Paris (POP), derived from calcined gypsum, tends to be pricier because of additional manufacturing steps and packaging expenses. In construction and art applications, gypsum powder remains the preferred choice for large-scale use, while POP is favored for detailed work despite its higher cost and comparatively limited availability.

Environmental Impact and Safety

Gypsum powder is a natural mineral primarily composed of calcium sulfate dihydrate, which makes it environmentally friendly due to its abundant availability and biodegradability. Plaster of Paris (POP), derived by heating gypsum to remove water, has a higher carbon footprint from energy-intensive calcination and releases dust that can cause respiratory issues, posing safety concerns during handling. Using raw gypsum powder reduces environmental impact and health risks compared to processed Plaster of Paris.

How to Choose: Gypsum Powder vs Plaster of Paris

Gypsum powder and Plaster of Paris (POP) differ primarily in composition and application, with gypsum powder being a raw, naturally occurring mineral form and POP a processed, quick-setting material derived from heating gypsum. When choosing between the two, consider gypsum powder for projects requiring slower setting times and higher workability, whereas POP suits rapid molding, casting, and detailed decorative work due to its fast hardening properties. Assess factors such as setting time, strength, project scale, and finish requirements to select the optimal material for construction or artistic applications.

Gypsum powder vs Plaster of Paris Infographic

materialdif.com

materialdif.com